Automatic measuring device for volume change of concrete

A volume change, automatic measurement technology, applied in the direction of material inspection products, etc., can solve the problem of not being able to accurately and automatically measure continuously, and achieve the effects of simple structure, convenient use and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

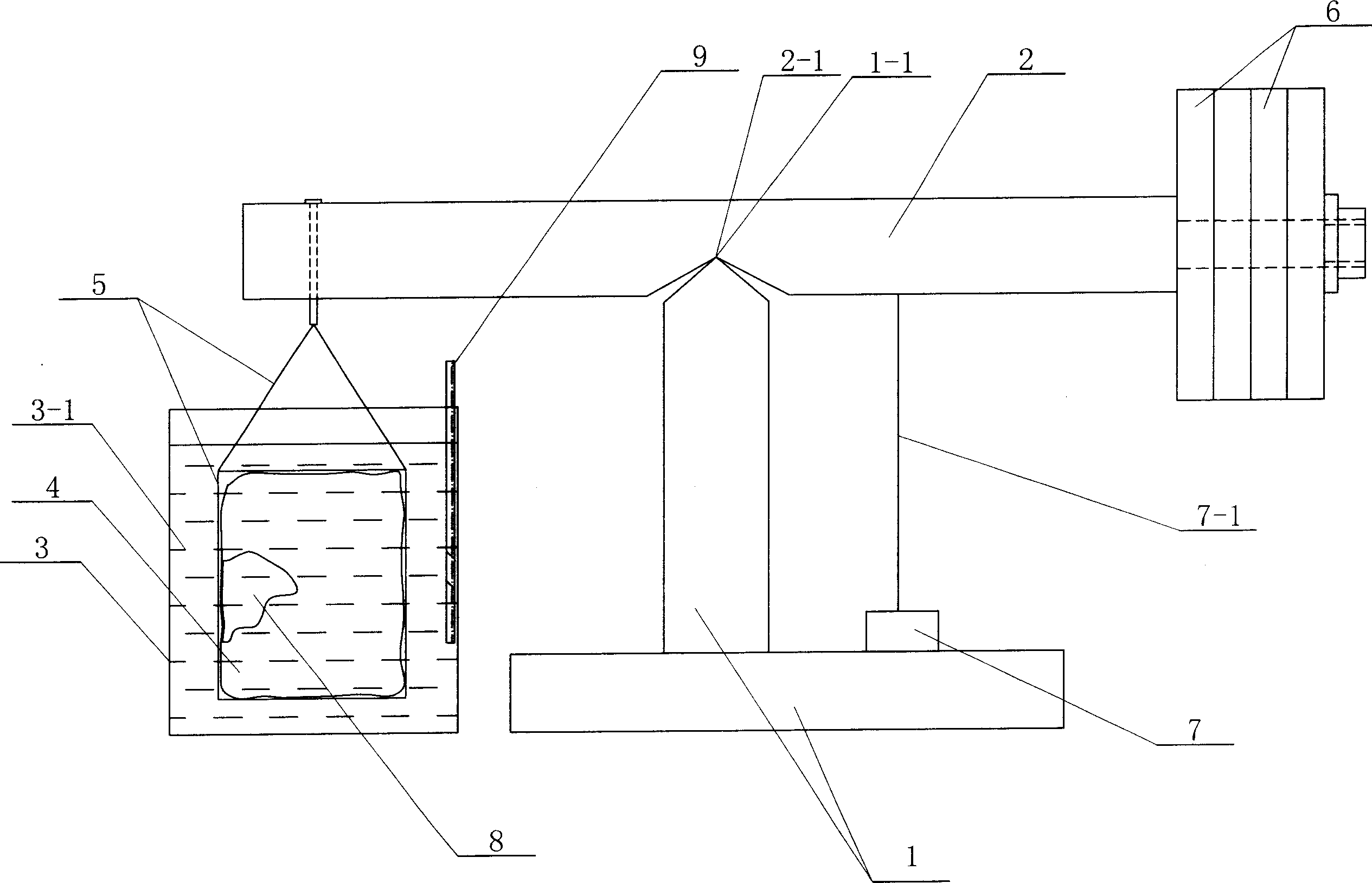

[0007] Specific embodiments: this embodiment is made up of support 1, balance beam 2, container 3, sealing rubber membrane 4, hanger 5, counterweight weight 6, tension sensor 7, thermometer 9; The upper apex 1-1 of support 1 is The sharp point is connected to the sharp groove of the lower end surface 2-1 of the middle part of the balance beam 2, the counterweight 6 is sleeved on the right end of the balance beam 2, and the upper end of the hanger 5 is connected to the left end of the balance beam 2. The concrete sample 8 is arranged in the sealing rubber membrane 4, and the sealing rubber membrane 4 is arranged in the hanger 5, and the sealing rubber membrane 4 is completely immersed in the liquid 3-1 in the container 3, and the sealing rubber membrane 4 and the hanger 5 is not in contact with the inner wall of the container 3, the base of the tension sensor 7 is connected to the upper right side of the bracket 1, the force detection end 7-1 of the tension sensor 7 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com