Hydroxycarboxylic Acids and Salts

a technology applied in the field of hydroxycarboxylic acids and salts, can solve the problems of limited condensed admixtures, including but not limited to, other chemical processes, and the lik

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

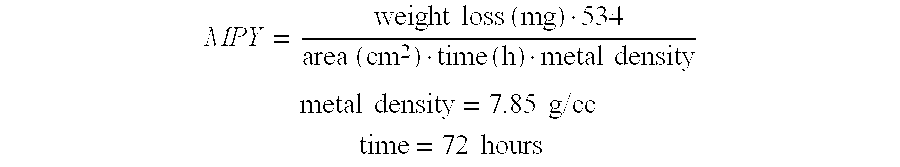

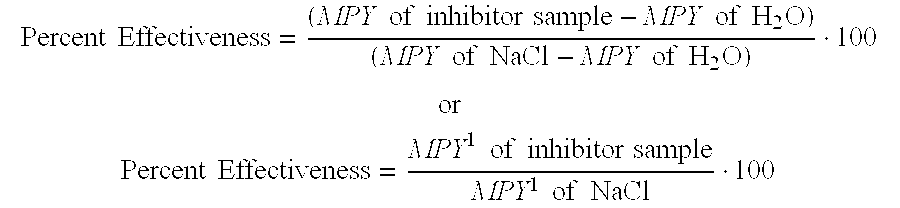

Corrosion Test Methods

[0027]Salt products prepared by the nitric acid oxidation methods and work up procedures described in this invention were evaluated for their corrosion inhibiting properties according to standard testing methods. Corrosion tests were performed according to the National Association of Corrosion Engineers (NACE) Standard TM0169-95 modified by the Pacific Northwest Snowfighters (PNS) (NACE TM0169-95).

[0028]The test procedure was modified to use 30 mL of a 3% solution of inhibitor per square inch of total coupon surface area. Stamped and numbered steel TSI coupons which met the ASTM F436 Type 1 requirement with a Rockwell hardness of C 38-45 were used for each corrosion test. Approximate coupon dimensions are 1.37 in. outer diameter,0.60 in. inner diameter, and 0.10 in. thickness with a density of 7.85 grams per cubic centimeter. Coupons were placed in a sealed container on a rock tumbler with a non-abrasive cleanser for 30 minutes to remove surface grease and impu...

example 2

Samples Prepared as Concrete Admixtures

[0037]The samples prepared as concrete admixtures were of the type listed in Table 2 Sample I being oxidation mixtures as described with no glucarate removed, Sample II being oxidation mixtures as described with some glucarate removed, and Sample III being a single admixture substance from the oxidation, i.e., monopotassium D-glucarate.[0038]I nitric acid oxidized 95-99% liquid dextrose[0039]II nitric acid oxidized 95-99% liquid less D-glucarate[0040]III monopotassium D-glucarate

[0041]A pH greater than 9 was established for Samples I-II by addition of sodium hydroxide, whereas the pH of the Sample III solution was established as greater than 9 by addition of potassium hydroxide.

A.—Admixture Sample Preparation

[0042]Numerous samples were prepared from the dextrose oxidation product to be tested as potential concrete admixtures. Each sample was varied by control of reaction conditions, work-up procedure and product analysis by ion chromatography f...

example 3

General Methods

[0048]Solutions were concentrated in vacuo (15-25 mbar) using a rotary evaporator and water bath at 50° C. pH measurements were made with a Thermo Orion 310 pH meter (Thermo Fisher Scientific, Inc., Waltham, Mass., USA) which was calibrated prior to use. Oxidations were carried out in Mettler Toledo LabMax reactor, designed to operate as a computer controlled closed-system reactor. The Labmax was fitted with a top-loading balance, a liquid feed pump, an oxygen Sierra flow valve, a mechanically driven stirring rod, a thermometer, a 2 liter thermal jacketed flask, an FTS recirculating chiller, a pressure manifold fitted with pressure relief valves and pressure gauge, and a personal computer with CamileTG v1.2 software. The software installed allows the operator to program experiments based on specific parameters and conditions. Oxidation procedures are readily changed as needed as illustrated in Examples 9-13.

[0049]Examples of, but not limited to, preparation of polyol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com