Temperature stress test-based same condition simulated maintenance test method and inversion simulated maintenance test method and system

A technology of temperature stress and test method, which is applied in the direction of controlling/regulating the system, controlling multiple variables at the same time, using stable tension/pressure to test the strength of materials, etc., and can solve problems such as the inability to test the mechanical properties of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

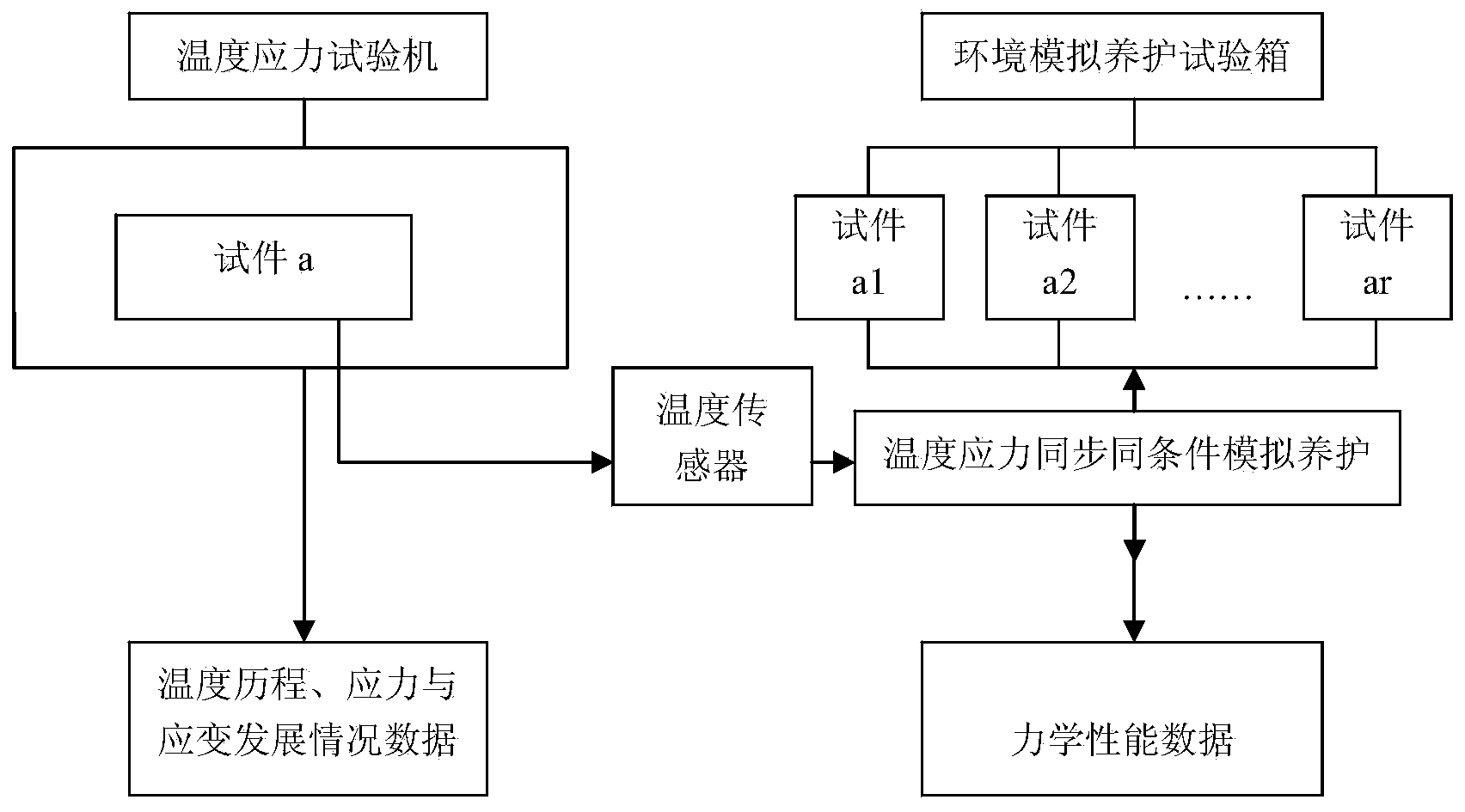

[0038] This example is an example of temperature stress test and maintenance under the same conditions, the specific process can be seen figure 2 .

[0039] (1) The system used in the same-condition curing test based on the temperature stress test in this example includes two devices: a temperature stress test machine and an environment simulation curing test box.

[0040] The temperature stress testing machine adopts the HYPY-II temperature stress testing machine of Beijing Hangyuan Pingyang Technology Development Co., Ltd., and its test mode includes several modes such as approximate adiabatic temperature rise, constant temperature control, and archived data matching.

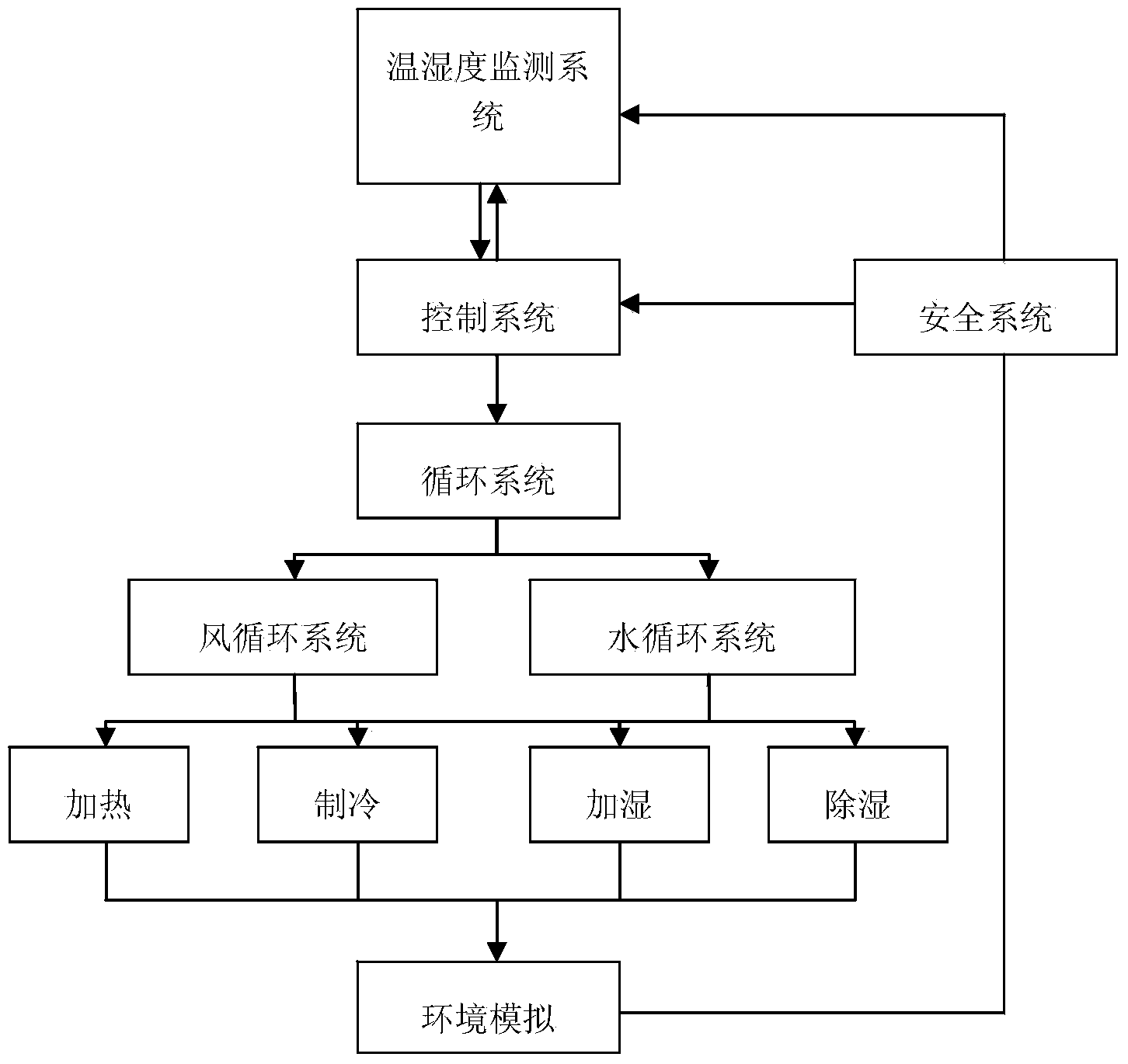

[0041] Environmental simulation maintenance test chamber such as figure 2 As shown, it has a working room, which can accommodate multiple concrete simultaneous curing specimens a1, a2,,,, ar, r is a natural number greater than or equal to 2, in addition, the environmental simulation curing test box also S...

Embodiment 2

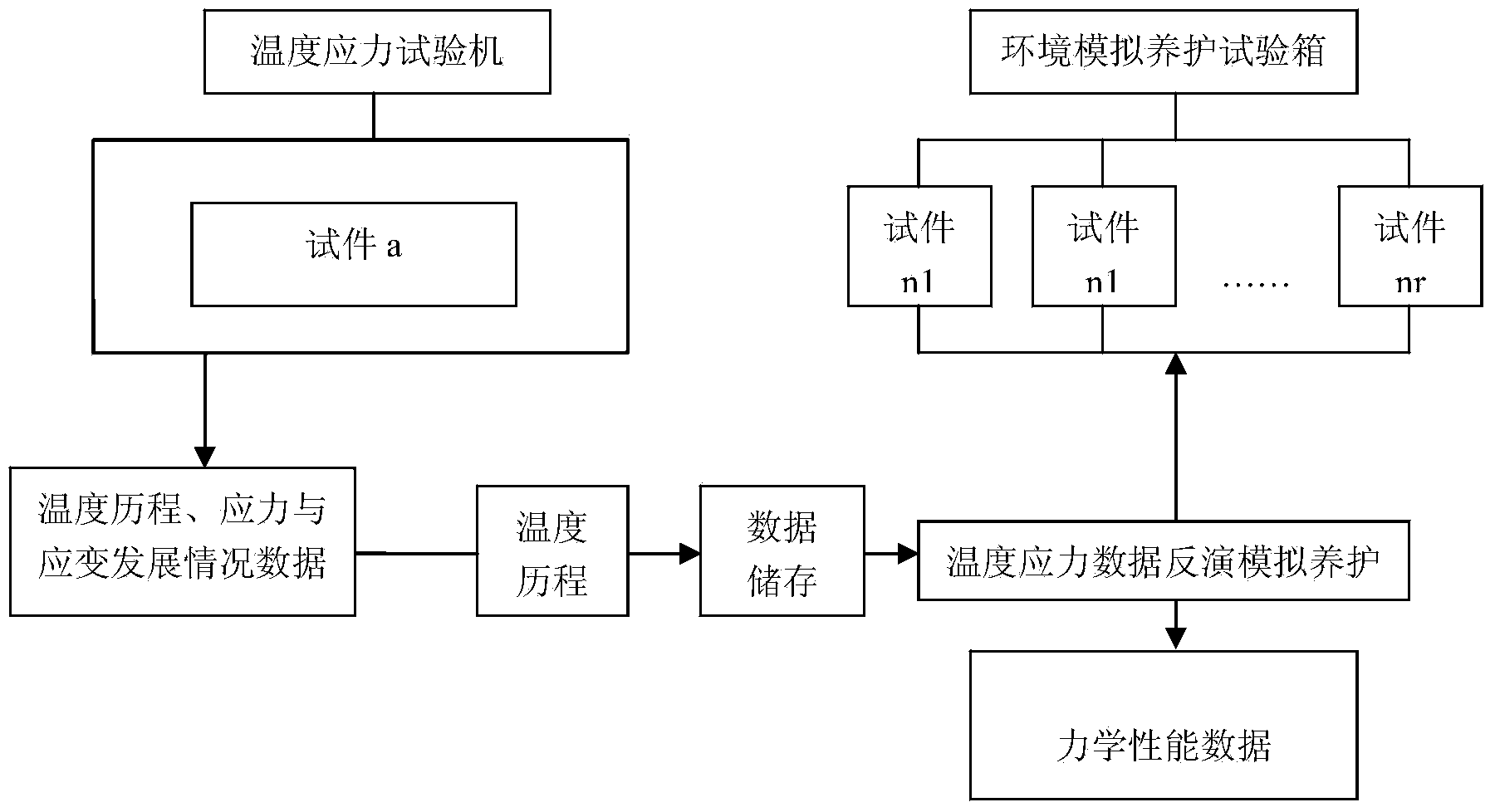

[0056] This example is a temperature and stress data inversion simulation test example, and its specific process can be seen in image 3 .

[0057] (1) The temperature stress data inversion simulation maintenance test system based on the temperature stress test in this example includes two parts: the temperature stress test machine and the environmental simulation maintenance test box.

[0058] The temperature stress testing machine adopts the HYPY-II temperature stress testing machine of Beijing Hangyuan Pingyang Technology Development Co., Ltd., and its test mode includes several modes such as approximate adiabatic temperature rise, constant temperature control, and archived data matching.

[0059] Environmental simulation maintenance test chamber such as figure 2 As shown, it has a working room, which can accommodate multiple concrete simultaneous curing specimens a1, a2,,,, ar, r is a natural number greater than or equal to 2, in addition, the environmental simulation cu...

Embodiment 3

[0075] Test the temperature stress test data and concrete mechanical performance data of a poured concrete pier under the same temperature history.

[0076] The concrete pier is a concrete pier that has been in normal use, and a temperature sensor is embedded inside the concrete solid component. Test its temperature history data and store that data.

[0077] Set up the system as shown in Example 2, import the temperature history data obtained by actual measurement into the temperature stress testing machine and the synchronous simulation curing test box respectively, and obtain the crack resistance of the concrete specimen in the temperature stress testing machine, and the early age Volume deformation, creep, stress relaxation, temperature sensitivity and other performance parameters; the environmental simulation curing test under the same conditions can measure the compressive strength, splitting tensile strength, flexural strength, elastic modulus and other mechanical prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com