System and method for temperature control and crack prevention intelligent monitoring of concrete dam

An intelligent monitoring system, temperature control and crack prevention technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as restricting the rapid construction of dams, meet complex construction and environmental conditions, and speed up construction. Process, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

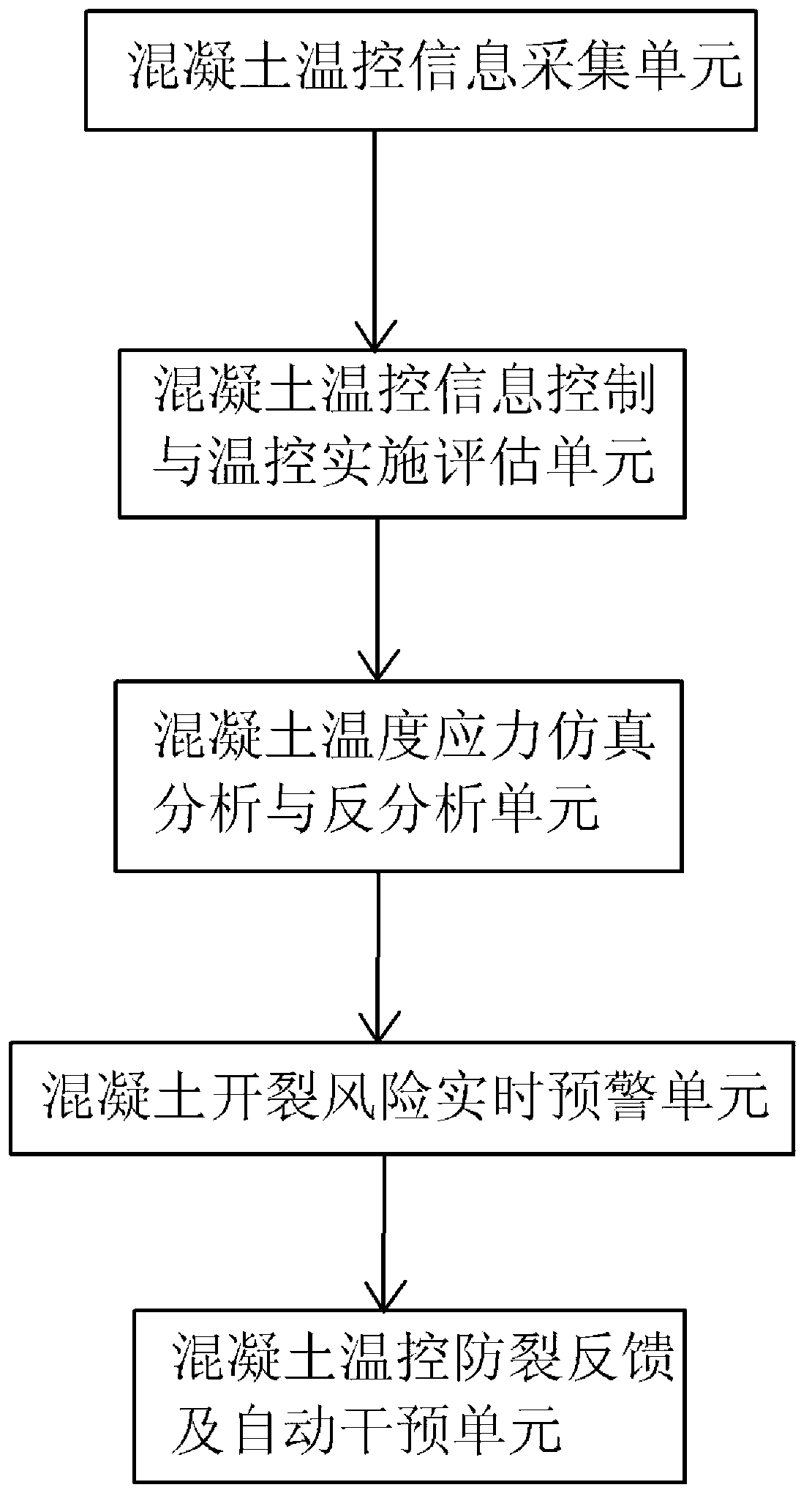

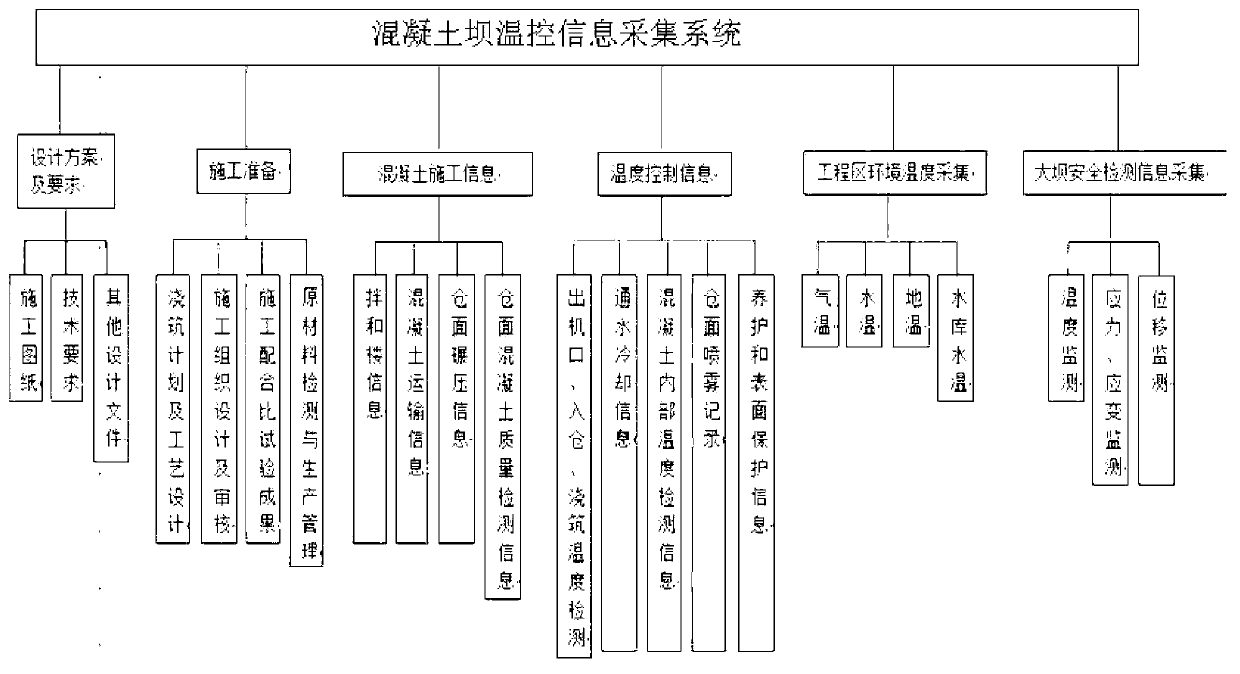

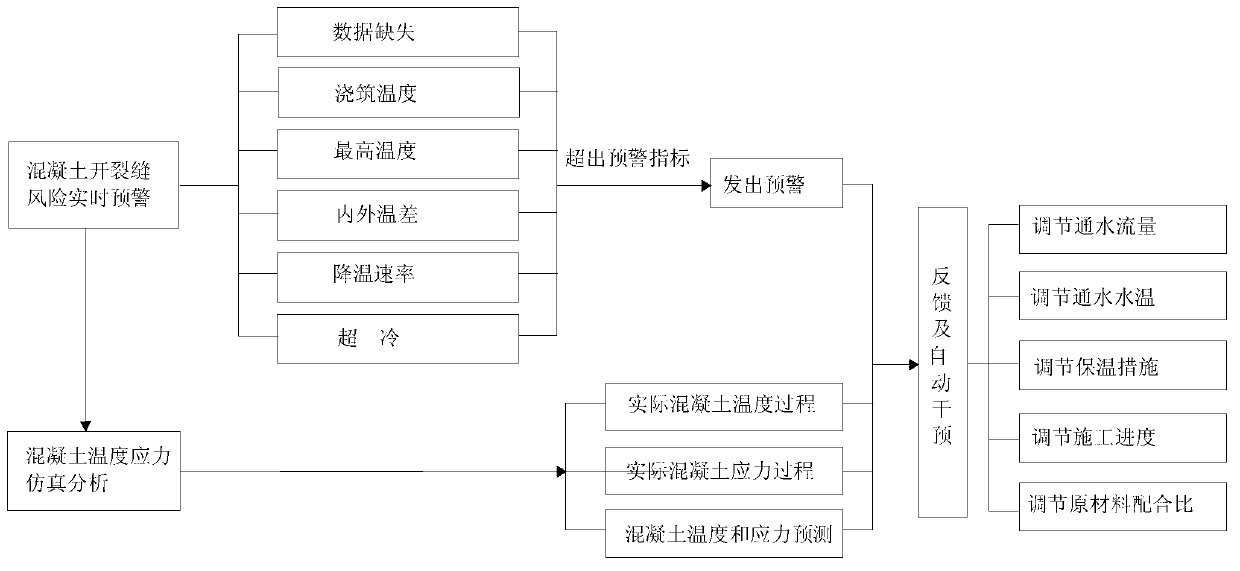

[0016] Such as figure 1 As shown, this concrete dam temperature control and anti-cracking intelligent monitoring system includes a concrete temperature control information acquisition unit (referred to as the concrete temperature control information acquisition system in the figure), a concrete temperature control information control and temperature control implementation evaluation unit, Concrete temperature stress simulation analysis and anti-analysis unit, concrete cracking risk real-time early warning unit, concrete temperature control anti-cracking feedback and automatic intervention unit, through the concrete temperature control information acquisition unit to collect the temperature control monitoring data information of the concrete dam in real time, the concrete temperature control The information control and temperature control implementation evaluation unit stores, controls, shares and evaluates the temperature control monitoring data information, and then through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com