Joggle-joint smart shield segment

A technology of tenon-joining shield pipes and shield segments, which is applied in wellbore lining, tunnel lining, underground chambers, etc., can solve the difficulty in collecting segment status information for shield segment operation and maintenance, and the large amount of shield segments used. and other problems, to achieve the effect of speeding up the construction process of the shield, making the occlusion firm, and improving the splicing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

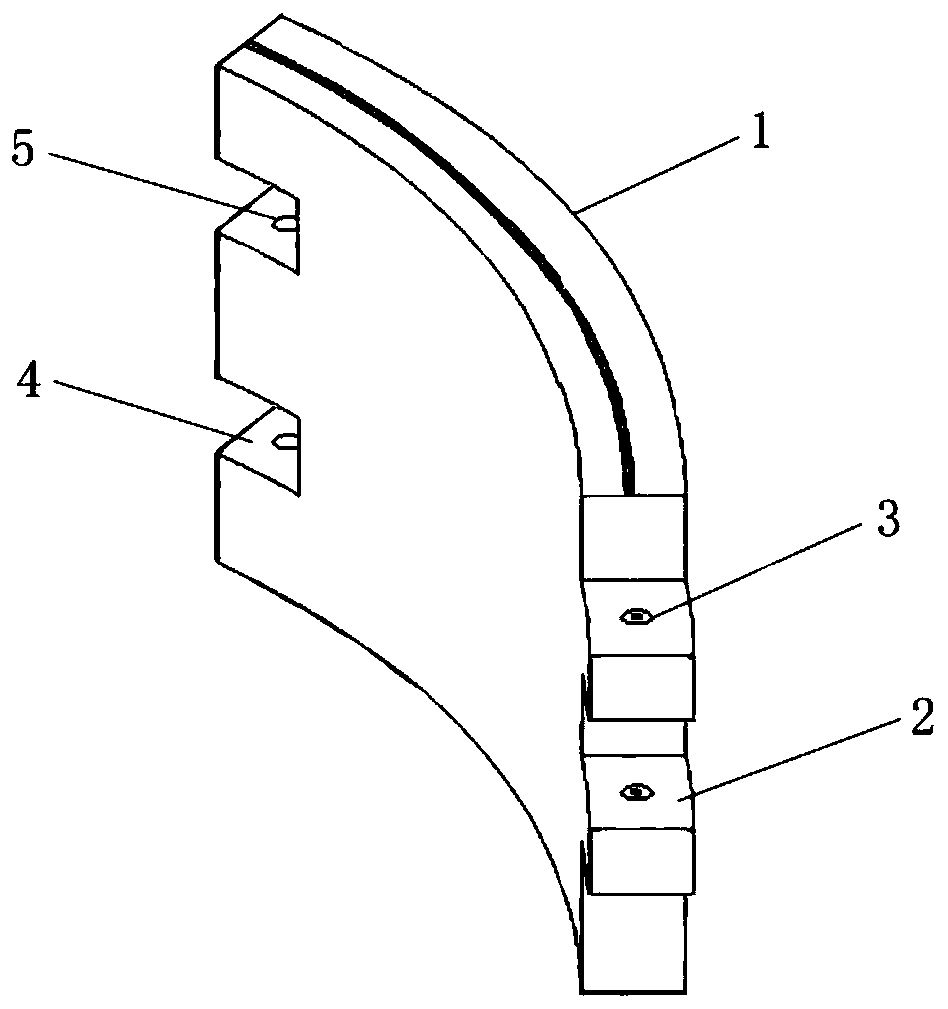

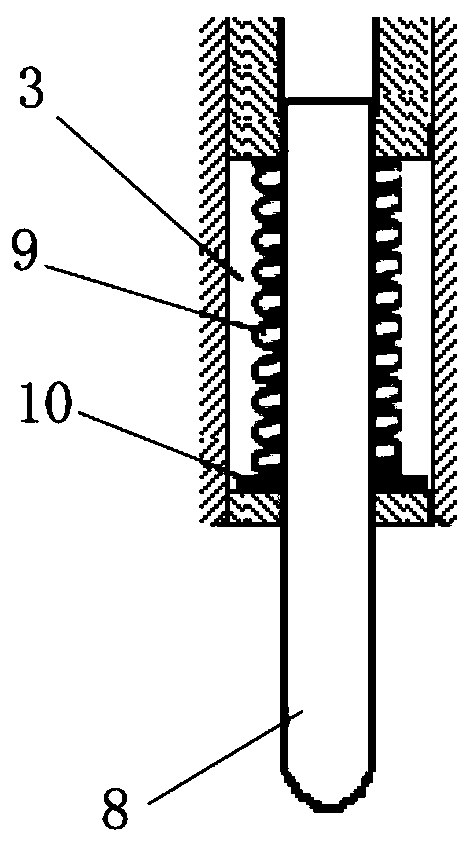

[0032] Such as figure 1 As shown, a mortise-joint shield segment includes a sheet body 1, and one end of the sheet body 1 having a ring upward has a first bump 2, and the other end of the sheet body 1 ring upward has a first bump 2 that coincides with the first bump 2. A card slot 4, a first pin hole 3 is formed on each longitudinal end surface of the first protruding block 2. Such as image 3 As shown, the first pin hole 3 has a first pin 8, the first pin 8 is covered with a spring 9, the front end of the first pin 8 has a stopper 10, and the two ends of the spring 9 are respectively against the first pin hole 3 bottom and first pin hole 3 front. The two longitudinal inner walls of the first slot 4 each have a second pin hole 5 that is matched with the first pin 8. When the first protrusion 2 is snapped into the first slot 4 on another shield segment, The first pins 8 respectively spring into the second pin holes 5 on another shield segment. There are two first protrusion...

Embodiment 2

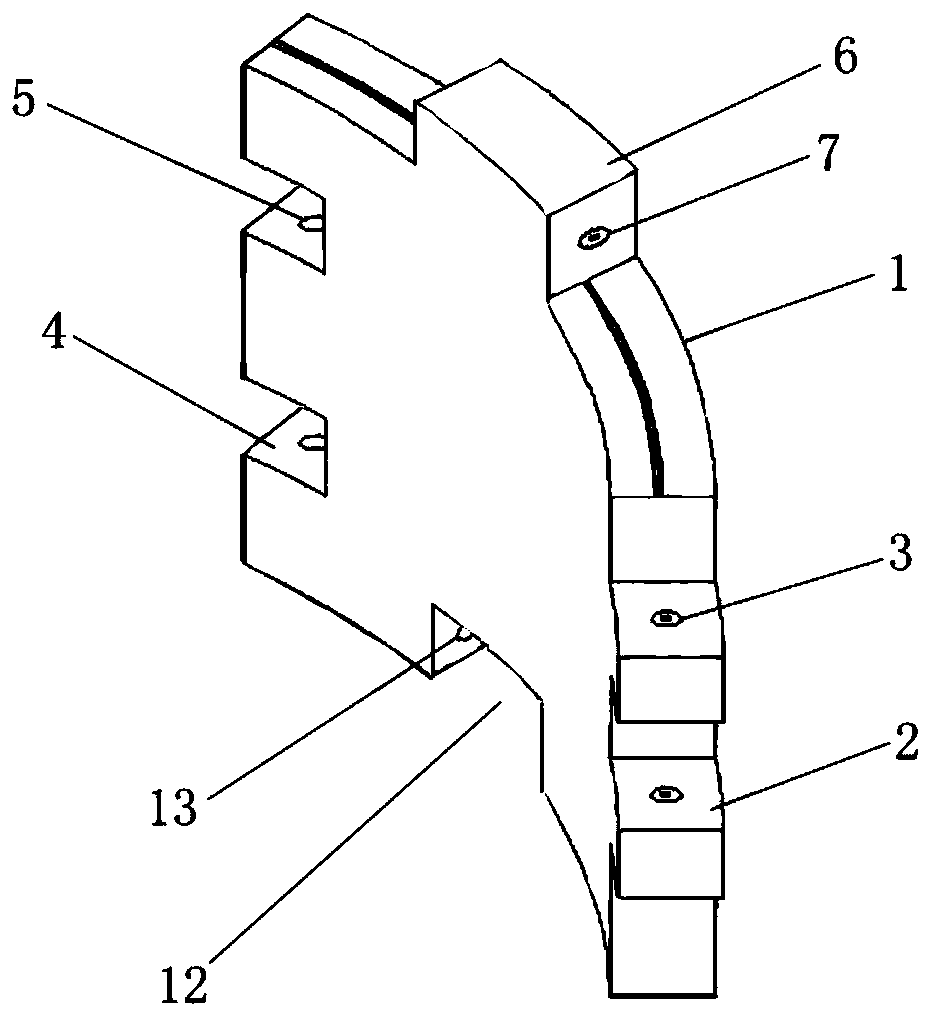

[0035] Such as figure 2 As shown, a mortise-joint shield segment includes a sheet body 1 , a first lug 2 is provided at one end of the sheet body 1 , and a first groove 4 is provided at the other end of the sheet body 1 . A first pin hole 3 is respectively arranged on the longitudinal end surface of the first protrusion 2 , and a first spring pin is arranged in the first pin hole 3 .

[0036] Such as image 3 As shown, the spring pin is covered with a spring 9, and the front end of the pin 8 has a catch 10, and the two ends of the spring 9 are against the bottom of the pin hole and the front end of the pin hole respectively.

[0037]The two longitudinal inner walls of the first slot 4 each have a second pin hole 5 that is matched with the first pin 8. When the first protrusion 2 is snapped into the first slot 4 on another shield segment, The first spring pins respectively spring into the second pin holes 5 on another shield segment. There are two first protrusions 2 and tw...

Embodiment 3

[0043] Such as Figure 5 and Figure 6 As shown, a shield segment with tenon joints includes a sheet body 1 , a circumferential screw groove 19 , a longitudinal screw groove 20 , and a sealing strip 23 . One end of the sheet body 1 has two tenons 22, and the other end has two tenon grooves 21. Both the tenon heads 22 and the tenon grooves 21 are arc-shaped grooves, and the curvature of the tenon heads 22 and the tenon grooves 21 is the same as that of the sheet body 1. When the shield segment is installed, the tenon 22 is inserted into the tenon groove 21. Since the curvature of the tenon 22 and the tenon groove 21 is the same as that of the intelligent sheet body 1, the arc-shaped circumferential screw grooves 19 at both ends of the two pieces 1 With automatic alignment, the arc-shaped bolts can pass through the circumferential screw groove 19 smoothly, which greatly reduces the difficulty of aligning the circumferential screw groove 19, improves the connection efficiency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com