Conveying and slurry preparing system for ready-mixed dry-blended sand for construction

A construction, dry mixing technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of slow transportation, affecting the construction environment, loss of mortar, etc., to reduce labor intensity and labor costs, and improve automation. degree, the effect of speeding up the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

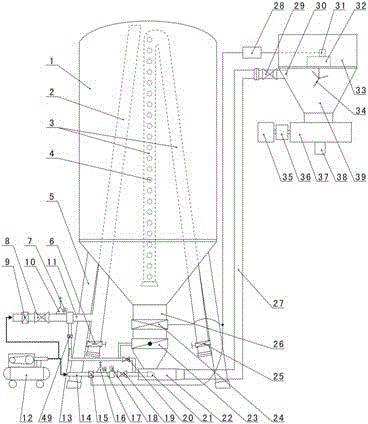

[0021] The present invention will be further described below in conjunction with accompanying drawing:

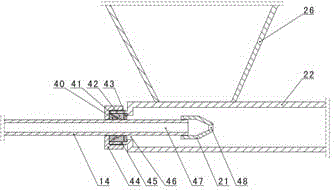

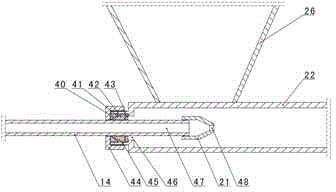

[0022] Such as figure 1 As shown, the ready-mixed dry-mixed sand material conveying and pulping system for construction of the present invention includes a storage tank 1, a stirring device, an air compressor 12 and a storage bin 39, and the bottom of the discharge pipe 16 of the storage tank 1 A blowing pipe 22 for blowing ready-mixed dry-mixed sand is installed in communication, a first air pipe 2 is installed in the storage tank 1, the upper end of the first air pipe 2 is located at the top in the storage tank 1, and the first air pipe 2 The lower end passes through the tank wall of the storage tank 1 and is placed outside the storage tank 1 and is used to connect the dust bag. The lower section of the first air pipe 2 is provided with a manual butterfly valve 6 near the lower end, and the lower section of the first air pipe 2 is located at the manual butterfly valve 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com