Biological extraction method of pineapple leaf fibers

A pineapple leaf fiber, biological extraction technology, applied in fiber processing, fiber mechanical separation, textiles and papermaking, etc., can solve the problems of limited removal of non-cellulose substances, high corrosion of equipment, environmental pollution, etc., to avoid fiber damage and/or loss, good quality, high softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

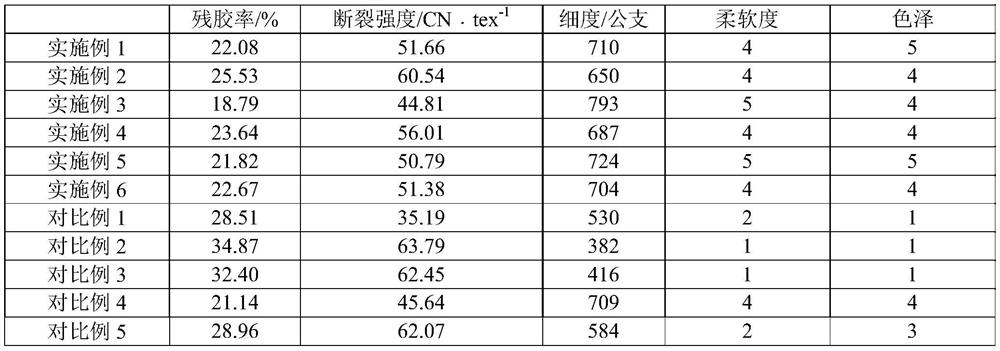

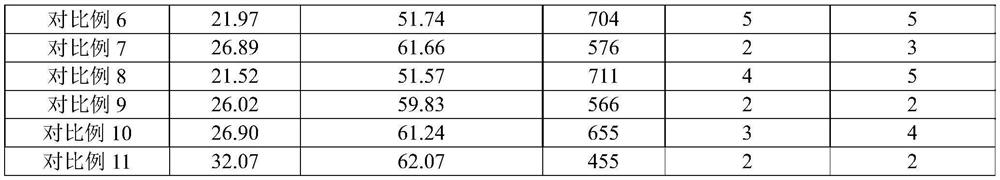

Examples

Embodiment 1

[0034] (1) mechanical treatment of pineapple blades: cut off the thorns on pineapple blade edges, adopt the mode of beating or rolling to make pineapple blades crack, and mechanically scrape off most of the mesophyll;

[0035] (II) Microbial treatment: inoculate Aspergillus niger spores in Chapei medium, culture at 36°C, 200r / min, shaker for 24h to obtain spore suspension, add 50mL / kg pineapple leaves to the mechanically treated pineapple leaves Spray the spore suspension of Aspergillus niger HYA4 evenly, incubate at 35°C for 4 days, wash with water, dry, knead and loosen to obtain the pineapple leaf fiber raw material;

[0036] (1) Enzyme treatment: the liquor ratio is 1:50 (kg / L), the pineapple leaf fiber raw material is added to pH 5.0, in the enzyme liquid containing 0.3wt% laccase and 0.3wt% xylanase, 45 ℃, enzymatic treatment for 4h;

[0037] (2) Enzyme inactivation and rinsing: Prepare a rinsing solution of 5g / L sodium silicate, 1.5g / L sodium hydroxide, and 10g / L hydro...

Embodiment 2

[0041] (1) mechanical treatment of pineapple blades: cut off the thorns on pineapple blade edges, adopt the mode of beating or rolling to make pineapple blades crack, and mechanically scrape off most of the mesophyll;

[0042](II) Microbial treatment: inoculate Aspergillus niger spores in Chapei medium, 30°C, 200r / min, shaker culture for 30h to obtain spore suspension, add 10mL / kg pineapple leaves to the mechanically treated pineapple leaves Spray the spore suspension of Aspergillus niger HYA4 evenly, incubate at 30°C for 7 days, wash with water, dry, knead and loosen to obtain the pineapple leaf fiber raw material;

[0043] (1) Enzyme treatment: according to the bath ratio of 1:50 (kg / L), the pineapple leaf fiber raw material is added to pH 5.0, in the enzyme solution containing 0.2wt% laccase and 0.2wt% xylanase, 50 ℃, enzymatic treatment for 4h;

[0044] (2) Enzyme inactivation and rinsing: Prepare a rinsing solution of 5g / L sodium silicate, 1g / L sodium hydroxide, and 8g / L...

Embodiment 3

[0048] (1) mechanical treatment of pineapple blades: cut off the thorns on pineapple blade edges, adopt the mode of beating or rolling to make pineapple blades crack, and mechanically scrape off most of the mesophyll;

[0049] (II) Microbial treatment: inoculate Aspergillus niger spores in liquid medium, culture on a shaker for 28 hours at 32°C and 200r / min to obtain a spore suspension, and add 50mL / kg of pineapple leaves to the mechanically treated pineapple leaves evenly Spray the spore suspension of Aspergillus niger HYA4, incubate at 35°C for 7 days, wash, dry, knead, and fluff to obtain the pineapple leaf fiber raw material;

[0050] (1) Enzyme treatment: the liquor ratio is 1:40 (kg / L), the pineapple leaf fiber raw material is added to pH 4.5, in the enzyme liquid containing 0.4wt% laccase and 0.4wt% xylanase, 50 ℃, enzymolysis treatment for 5h;

[0051] (2) Enzyme inactivation and rinsing: Prepare a rinsing solution of 4g / L sodium silicate, 1.5g / L sodium hydroxide, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com