Antistatic wear-resistant non-woven fabric for manufacturing dust-free wiping paper and treatment method thereof

A technology of dust-free wiping paper and treatment method, which is applied in non-woven fabrics, fiber treatment, textiles and papermaking, etc., and can solve problems such as spinneret hole blockage, weak long-fiber cohesion, and poor wear resistance. Achieve the effect of not easy to fall off, long-lasting antistatic performance and long-lasting antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

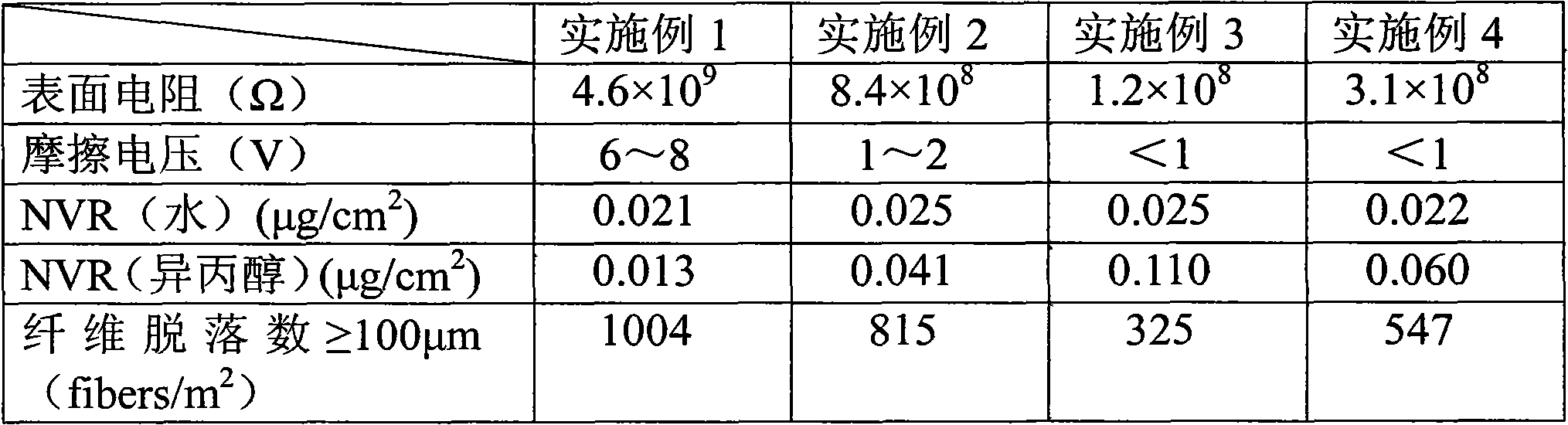

Examples

Embodiment 1

[0022] The antistatic wear-resistant nonwoven fabric is made by coating the surface of the spunlace nonwoven fabric combined with 50% viscose staple fiber and 50% polyester staple fiber by coating the hexamethylolmelamine resin coating combined with an antistatic agent.

[0023] Antistatic wear-resistant non-woven fabric treatment method comprises the following steps:

[0024] (1) prepare antistatic coating solution, at first 0.5% hexamethylol melamine resin, 0.05% malonic acid, 0.1% dodecyl dimethyl hydroxyethyl quaternary ammonium salt and water are made mixed solution, stir Evenly put into the padding tank;

[0025] (2) The antistatic coating solution is coated on the non-woven fabric through a dip coating process, and the scrap rate is controlled at 70%.

[0026] (3) Dry the non-woven fabric containing the antistatic coating solution at a temperature of 60° C. for 10 minutes.

[0027] (4) Packaging the dried non-woven fabric into rolls to obtain a wear-resistant non-wove...

Embodiment 2

[0031] The antistatic and wear-resistant nonwoven fabric made by coating the surface of the spunlace nonwoven fabric combined with 70% Lyocell and 30% polyester staple fiber combined with an antistatic agent hexamethylol melamine resin coating. Antistatic wear-resistant non-woven fabric treatment method comprises the following steps:

[0032] (1) prepare antistatic coating solution, at first 1.0% hexamethylol melamine resin, 0.1% malonic acid, 1.0% octadecyl dimethyl hydroxyethyl quaternary ammonium salt and water are made mixed liquor, stir Evenly put into the padding tank.

[0033] (2) The antistatic coating solution is coated on the non-woven fabric through a dip coating process, and the scrap rate is controlled at 90%.

[0034] (3) Dry the non-woven fabric containing the antistatic coating solution at a temperature of 100° C. for 5 minutes.

[0035] (4) Packaging the dried non-woven fabric into rolls to obtain a wear-resistant non-woven fabric with antistatic function. ...

Embodiment 3

[0039] The antistatic and wear-resistant nonwoven fabric is made by coating the surface of the spunlace nonwoven fabric combined with 50% viscose staple fiber and 50% polyester staple fiber by coating a hexamethyl etherated methylol melamine resin coating combined with an antistatic agent. Antistatic wear-resistant non-woven fabric treatment method comprises the following steps:

[0040] (1) Prepare antistatic coating solution, at first 5% hexamethyl etherified methylol melamine resin, 0.5% ammonium sulfamate, 4% octadecyl dimethyl hydroxyethyl quaternary ammonium salt and water are mixed liquid, stirred evenly and put into the padding tank.

[0041] (2) The antistatic coating solution is coated on the non-woven fabric through a dip coating process, and the scrap rate is controlled at 70%.

[0042] (3) Dry the non-woven fabric containing the antistatic coating solution at a temperature of 110° C. for 1 min.

[0043] (4) Packaging the dried non-woven fabric into rolls to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com