Polyvinyl alcohol master batch-polylactic acid composite fiber and application thereof

A polyvinyl alcohol masterbatch and composite fiber technology, applied in the direction of fiber chemical characteristics, conjugated synthetic polymer artificial filament, drilling composition, etc., can solve the problem that the performance cannot be further prepared, and the composite material cannot meet the multiple thermal requirements Stretch, good fiber and other problems, to achieve the effect of significant increase in production, high strength, short flowback time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Add 10 parts (weight) of amide compounds with a boiling point greater than 200°C to 90 parts (weight) of polyvinyl alcohol with a degree of polymerization of 1500 and a degree of alcoholysis of 95% (mol), at a temperature of 30 to 100°C Stirring and mixing for 10 hours, the mixed and modified polyvinyl alcohol is melted and extruded through a screw extruder, cooled to 20-40° C., and pelletized by a pelletizer to obtain a polyvinyl alcohol masterbatch.

[0053] Mix the above-mentioned polyvinyl alcohol masterbatch with 45 parts of polylactic acid at a temperature of 30-100°C for 0.5-4 hours, and then melt-extrude the blended modified product, pre-filter, spin, pre-stretch and coil , to obtain primary fibers, wherein the blended modified product is spun through a spinneret in a molten state, and the spinning temperature is 100-170 ° C. After spinning, the molten fluid is blown with gas, and the pre-stretching ratio is 3 times.

[0054] Then the as-spun fibers a...

Embodiment 2-6

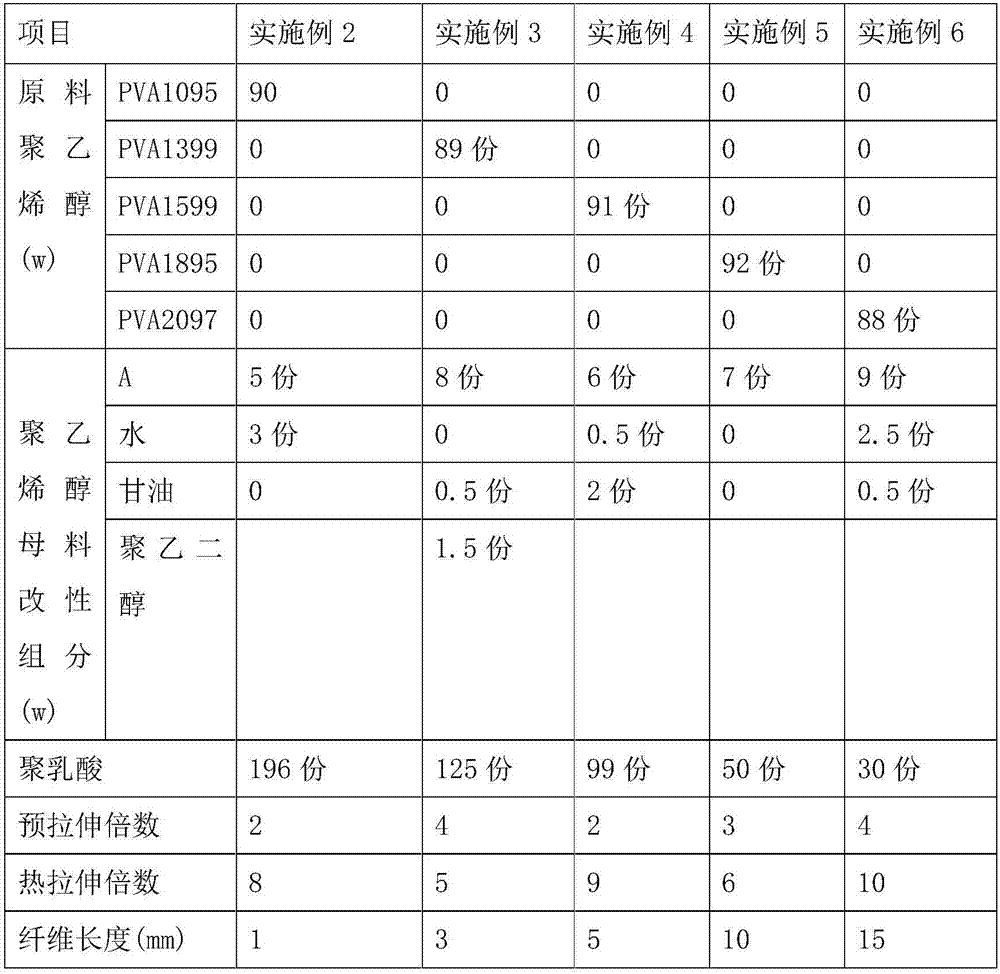

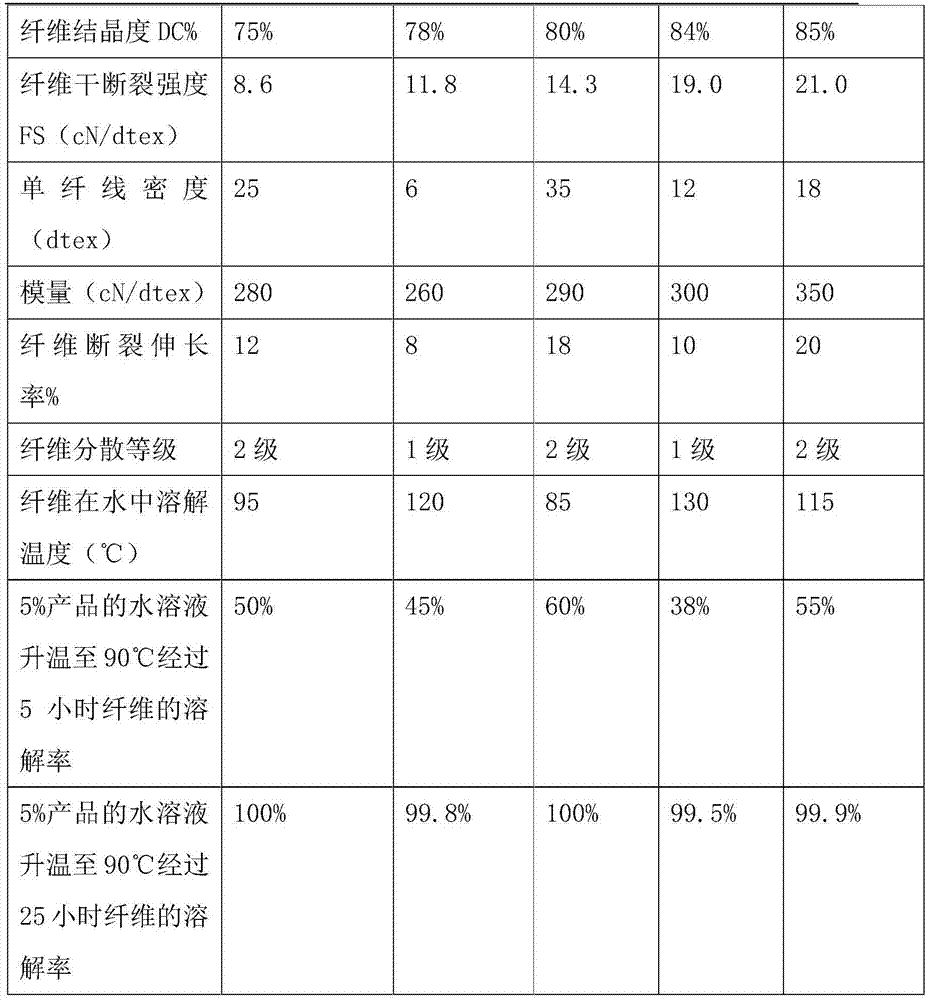

[0056] Embodiment 2-6: See attached table 1 for specific conditions, and others are the same as embodiment 1.

Embodiment 7

[0057] Embodiment 7: The polyvinyl alcohol masterbatch-polylactic acid composite fiber described in any one of Embodiments 1-6 is used for oil and gas field fracturing fluid, and the amount of composite fiber added accounts for 0.5% of the total weight of the temporary plugging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Dry breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com