External pressure-type hollow fiber membrane module with antipollution structure and cleaning system

A cleaning system and external pressure technology, applied in the field of water treatment system manufacturing, can solve the problems of unscientific connection between U-shaped membrane wire and membrane shell, broken wires, etc., to accelerate discharge, reduce the probability of broken wires, and restore membrane continuity. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

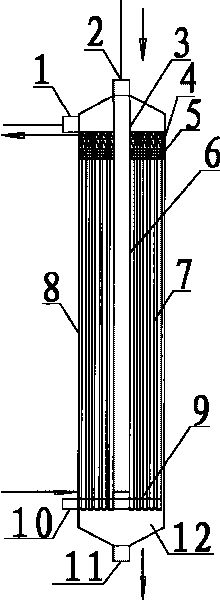

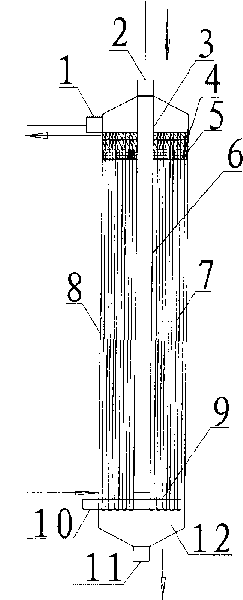

[0011] Embodiment 1: with reference to attached figure 1 . External pressure hollow fiber membrane module with anti-pollution structure, including water production pipe 1, raw water pipe 2, central water distribution pipe 3, central water distribution hole 6, U-shaped membrane wire 7, membrane shell 8, aeration device 9, air intake pipe 10. Concentrated water pipe 11, pollutant enrichment area 12, U-shaped membrane filament 7 is cast vertically on the upper end of the membrane shell and hangs down naturally, the lower end of the U-shaped membrane module is arranged with an air distribution system, and pollutants are arranged below the air distribution system enrichment area.

[0012] The U-shaped membrane wire 7 is vertically arranged inside the upper end of the membrane shell 8 and is single-ended cast on the upper end of the membrane shell 8. The U-shaped membrane wire 7 is cast with two layers of glue, and the first layer of glue 4 has a higher water hardness. The strengt...

Embodiment 2

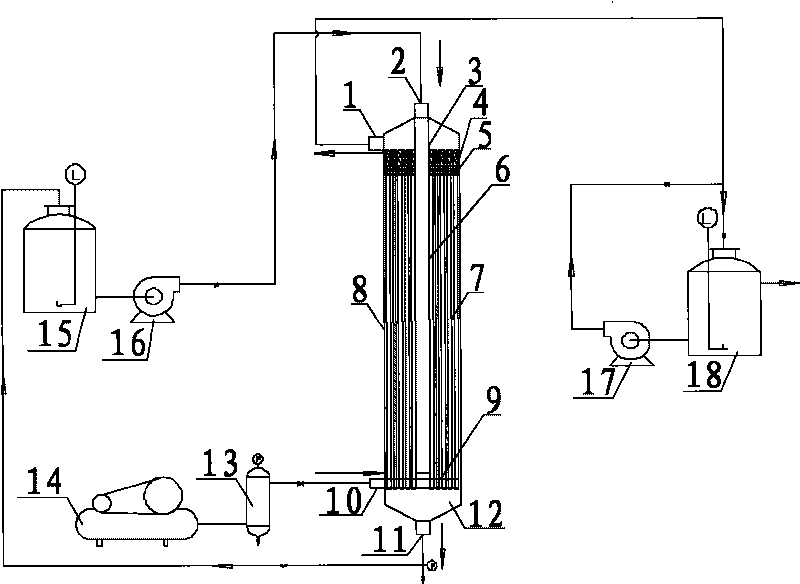

[0015] Embodiment 2: with reference to attached figure 2 . On the basis of Example 1, the cleaning system composed of external pressure hollow fiber membrane modules, which includes external pressure hollow fiber membrane modules, is characterized in that: the raw water pipe 2 inlet in the external pressure hollow fiber membrane modules The booster pump 16 is communicated with the outlet of the raw water tank 15; the concentrated liquid pipe 11 in the external pressure type hollow fiber membrane module is communicated with the inlet of the raw water tank 15 through a pipeline, and is communicated with the 6# valve; the external pressure type hollow The inlet pipe 10 in the fiber membrane module is connected with the outlet of the storage tank 13, and the inlet of the storage tank 13 is connected with the air outlet of the air compressor 14; Connected, communicated with the 18 inlets of the produced water tank.

[0016] A 1# valve is provided between the outlet of the booste...

Embodiment 3

[0017] Embodiment 3: On the basis of Examples 1 and 2, the cleaning method of the cleaning system composed of the external pressure type hollow fiber membrane module, it includes the external pressure type hollow fiber membrane module and the cleaning system composed of the external pressure type hollow fiber membrane module Cleaning system, (1) During normal operation, open 1#, 3#, 5#, 6# valves, close 2#, 4# valves, turn on the booster pump 16, the raw water enters the membrane module from the raw water pipe 2, and the concentrate Part of the liquid pipe 11 returns to the raw water tank 15 and part of it is discharged. The fresh liquid is collected by the water production pipe and then enters the water production tank 18; (2) The cleaning process consists of air flushing-backwashing-forward flushing, and 4# and 6# are opened during air flushing , close the 5#, 1#, 2#, 3# valves, open the air compressor 14 and adjust the pressure through the storage tank 13, so that the gas vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com