Laser accurate drilling method and device of fiber composite aircraft panel

A fiber composite material, aircraft wall panel technology, applied in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of fast tool wear, low precision, easy damage to materials, etc., to achieve the effect of easy use and overcoming wire drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Method example:

[0038] The length × width × thickness = 5000mm × 1800mm × 4mm fiber composite material aircraft panel with curvature is precisely drilled, the positioning accuracy is controlled within 0.02mm, the hole requirement: Φ8±0.05mm; for reliable connection, along the Make a hole every 30mm. The specific implementation steps are as follows:

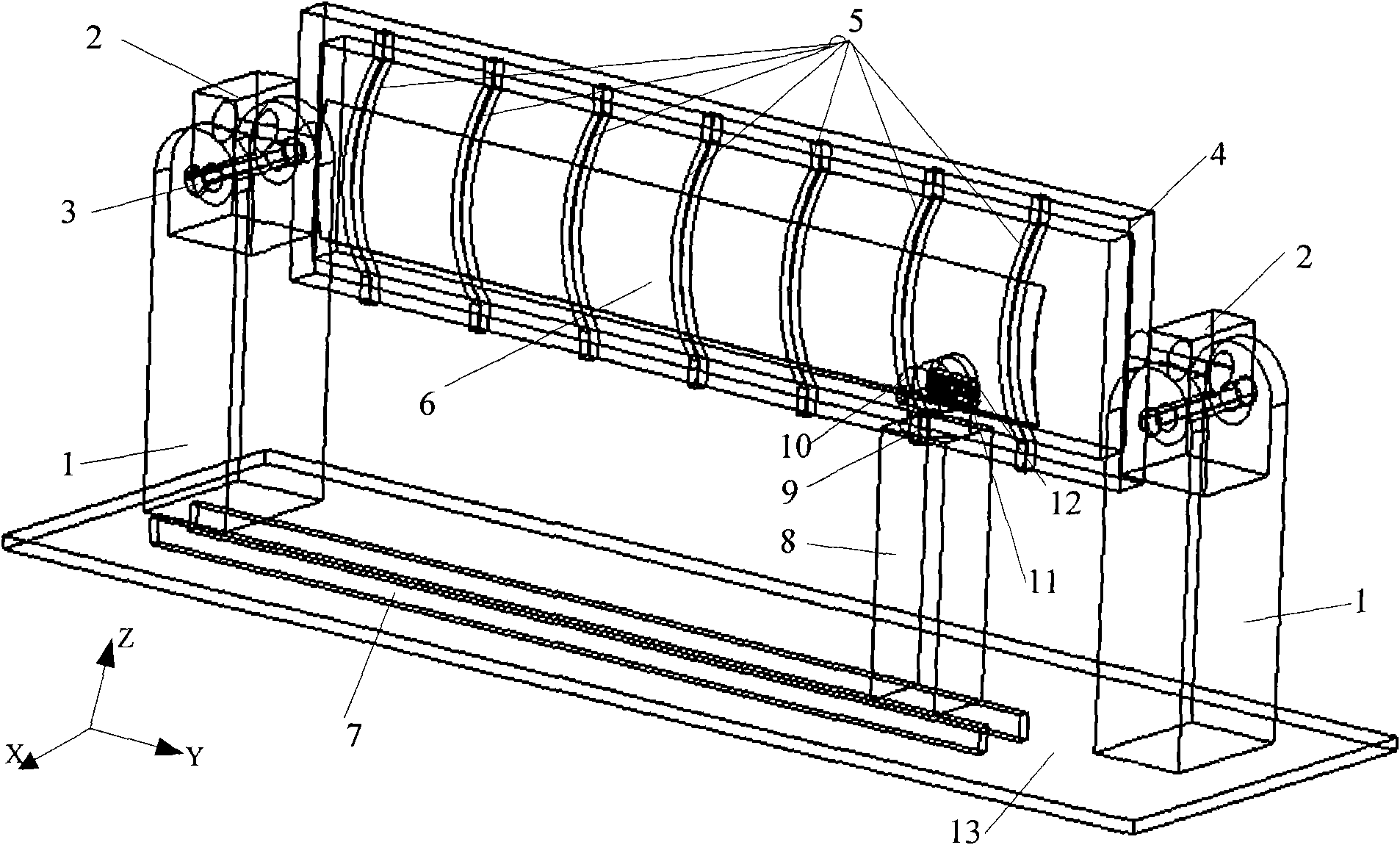

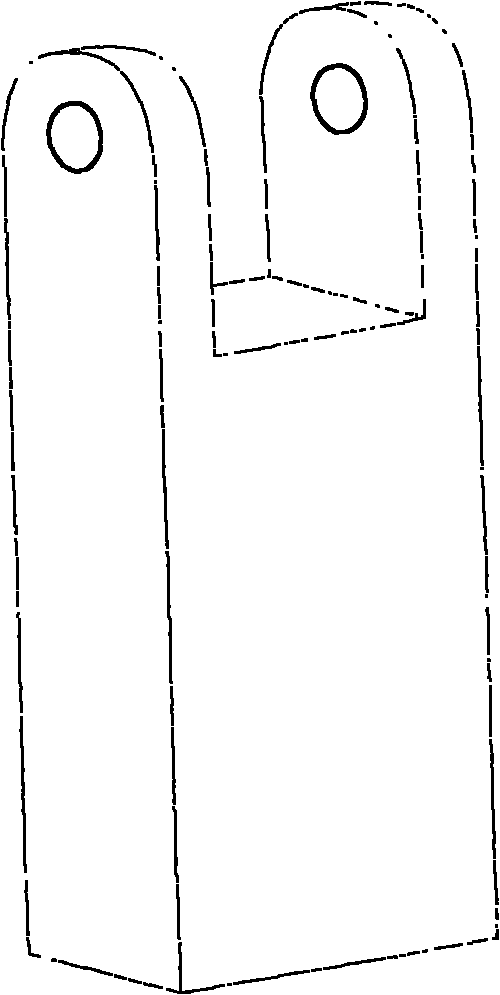

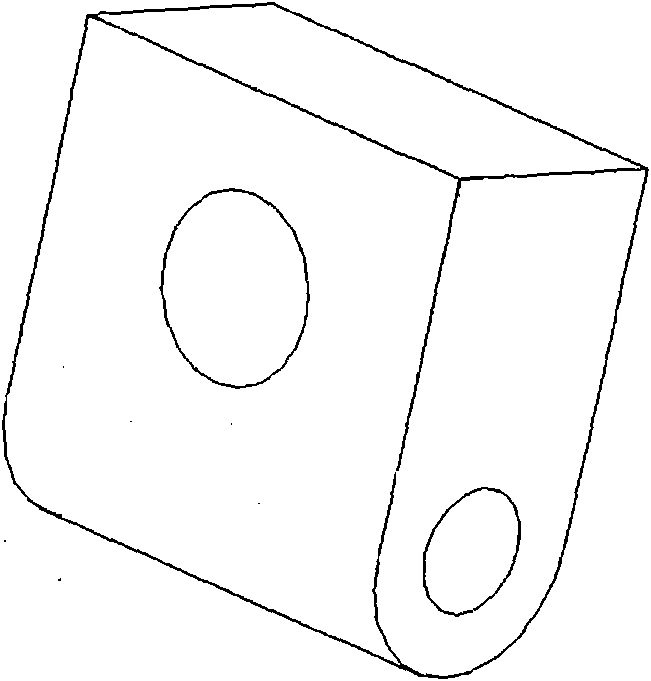

[0039](1) According to the structure and shape characteristics of the fiber composite material aircraft panel 6, the clamping plate 5 for installation and positioning of the panel is selected, and the positioning method of the assembly jig is selected in order to maintain the accuracy of the shape of the panel. Under the constraints of a positioning accuracy of 0.02mm, according to the positioning requirements of the wall boards, the clamping boards are distributed and installed on the frame 4; the height of the two columns 1 is driven by the control system, so that the spanning direction of the wall boards is parallel t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com