Method for preparing fiber prepreg filaments by hot-melt method and device thereof

A technology of prepreg and hot-melt method, applied in the field of fiber pre-preg by hot-melt method, can solve problems such as frequent downtime and belt change, and achieve the effects of improving comprehensive performance, reducing frequency and avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

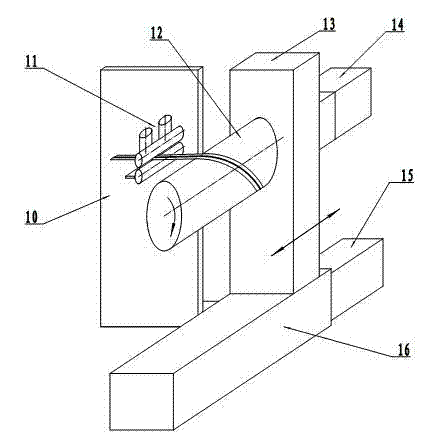

[0027] In the following, for the above purpose, a feasible implementation example of the design will be described in detail in conjunction with the accompanying drawings.

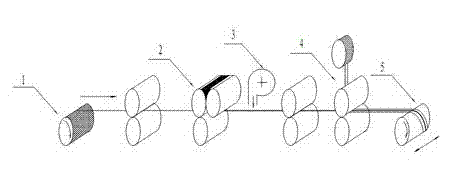

[0028] The invention provides a hot-melt prepreg machine for preparing fiber prepreg, which includes an unwinding device 1, a dipping device 2, a cooling device 3, a film adding device 4, a winding device 5, and a tension controller 6 , winding controller 7, overall controller 8 and temperature pressure control device 9, wherein,

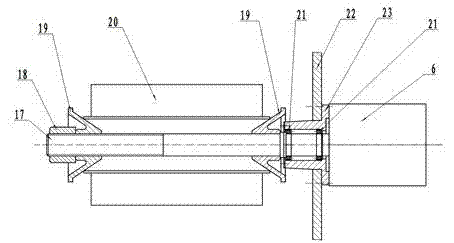

[0029] Described unwinding device 1 comprises rotating shaft 17, locking nut 18, clamping block 19, bearing 21, bearing block 23 and support plate 22, rotating shaft 17, locking nut 18 and clamping block 19 are formed by bearing 21, bearing block 23 and support plate 22 support, fiber bobbin 20 is installed in the middle of two clamping blocks 19 and is locked into one body with rotating shaft 17 by lock nut 18, and fiber bobbin 20 and rotating shaft can rotate around the axis to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com