Bionic composite material disc spring part and preparation method thereof

A bionic composite material and composite material technology, applied in the field of bionic composite disc spring parts and its preparation, can solve the problem of low forming pressure and achieve the effects of ensuring dimensional accuracy, easy and sufficient infiltration, and process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0057] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

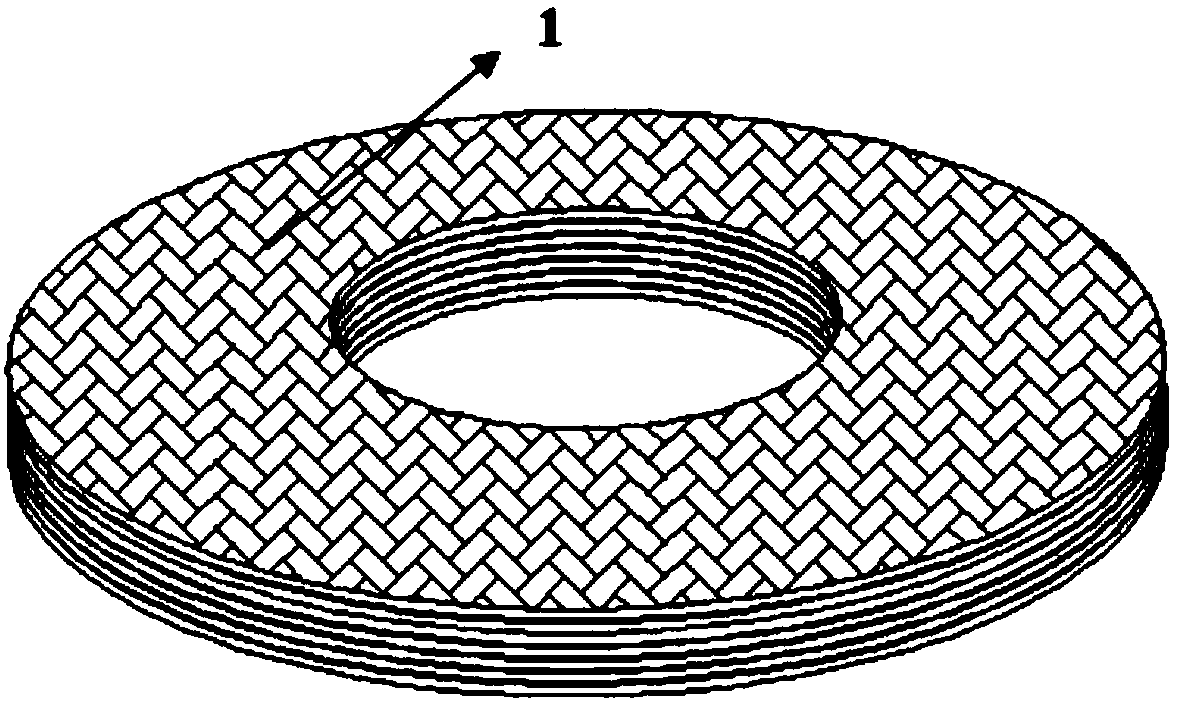

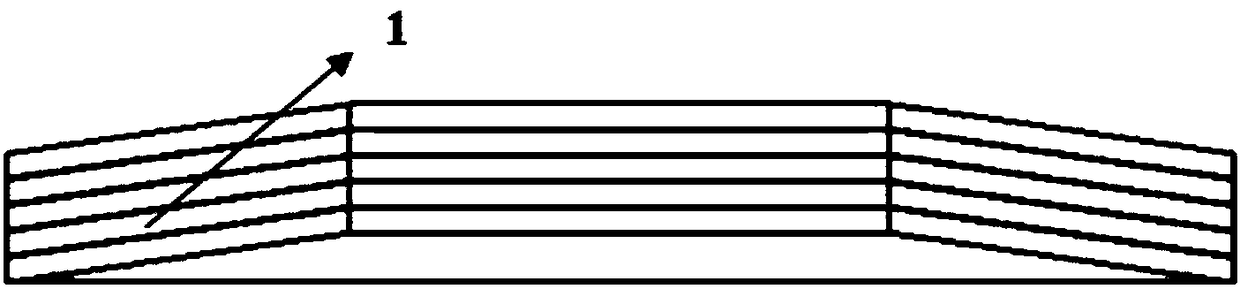

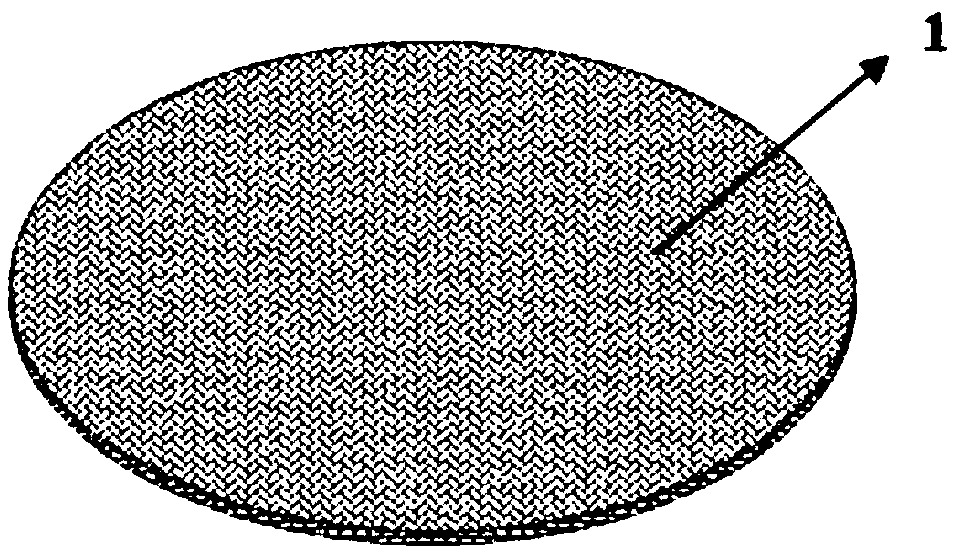

[0058] The invention discloses a bionic composite disc spring part, such as figure 1 As shown, the disc spring part is formed by fully infiltrating the fiber reinforced layer structure with the resin with filler; the fiber reinforced layer structure is a shell-like multi-layer fiber reinforced layer structure, and the fiber reinforced body The shape of the fiber reinforced body 1 is the same as the external shape and size of the prefabricated disc spring. In this embodiment, it is a circular ring cut according to the external shape and size of the prefabricated disc spring. Such as Figure 3a and Figure 3b shown;

[0059] In order to further improve the strength and isotropy of the bionic composite disc spring part of the present invention, the fiber of the fiber reinforce...

Embodiment 1

[0064] The process of "finishing the fiber reinforcement layer through online infiltration with resin" refers to: cutting the fiber reinforcement according to the shape and size of the prefabricated disc spring parts, and laying up layers to form a layer structure; in the infiltration mold with a special structure The process of making composite material disc spring parts after fully infiltrating and curing on-line with resin, the specific preparation process is as follows:

[0065] Step 1: cutting fiber reinforcement 1;

[0066] In this embodiment, the fiber reinforced body 1 is cut twice. First, the fiber reinforced body 1 is cut according to the planar projection shape of the prefabricated part, such as Figure 3a shown; then, the fiber reinforced body 1 after the primary cutting is subjected to secondary cutting according to the geometric shape and size matched with the disc spring mould, as Figure 3b As shown, thereby completing the cutting of the fiber reinforced body ...

Embodiment 2

[0079] The process of "prepreg made of fiber reinforcement by off-line infiltration of resin, and then cured by heating the mold" refers to: cutting the prepreg of fiber reinforcement made by off-line infiltration according to the shape and size of the prefabricated disc spring parts, Then the fiber reinforced body prepreg is laminated in multiple layers to form a fiber reinforced body layer structure, and is cured in a heating mold through a hot pressing process to make a composite disc spring part. The specific preparation process is as follows:

[0080] Step 1: According to the volume ratio of fiber resin, the pre-prepared resin is infiltrated off-line to make a fiber reinforced body prepreg;

[0081] Step 2: Cut the fiber reinforced body prepreg according to the shape and size of the prefabricated disc spring parts;

[0082] Step 3: lay out the multi-layer cut fiber reinforced prepreg layer by layer on the surface of the heating mold to form a fiber reinforced layer struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com