Process for producing high-speed gum-dipping printing decorative base paper

A technology for decorating base paper and production process, which is applied in paper, papermaking, textiles and papermaking, etc. It can solve the problems of affecting the absorption speed of base paper, affecting the speed of dipping, and cannot meet the high-speed dipping, so as to enhance the performance of glue absorption and improve production. Efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

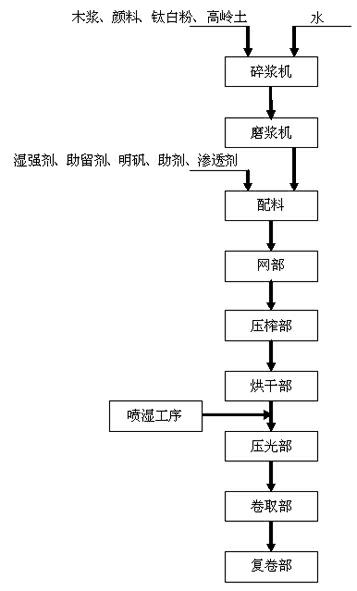

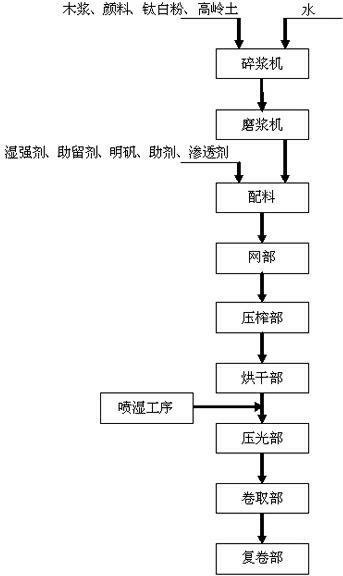

[0019] Reference figure 1 The production process steps of the high-speed dipping printing decorative base paper of the present invention are as follows:

[0020] The first step: pulping, through the pulping equipment, wood pulp, titanium dioxide, pigments and water are evenly mixed to prepare a slurry with a mass percentage of 6.0%. The required raw materials include 10% by weight Softwood pulp, 60% hardwood pulp, 15% titanium dioxide, 12% kaolin and 2.5% pigment; the pigment is composed of iron oxide;

[0021] The second step: refining, through the high-speed rotating friction and squeezing of the refining equipment, so that the pulp after pulping can achieve the required cutting and splitting, and make wood pulp, titanium dioxide and pigments The mixing is more uniform and the mutual bonding is tighter. The slurry is configured into a slurry with a mass percentage concentration of 5.5%, a tapping degree of 33°SR, and a wet weight of 2.0-2.5g;

[0022] The third step: batching, f...

Embodiment 2

[0025] Reference figure 1 The production process steps of the high-speed dipping printing decorative base paper of the present invention are as follows:

[0026] The first step: pulping, through the pulping equipment, wood pulp, titanium dioxide, pigments and water are evenly mixed to prepare a slurry with a mass percentage of 6.3%. The required raw materials include 12% by weight Softwood pulp, 58% hardwood pulp, 17% titanium dioxide, 10% kaolin and 2% pigment; the pigment is composed of iron oxide;

[0027] The second step: refining, through the high-speed rotating friction and squeezing of the refining equipment, so that the pulp after pulping can achieve the required cutting and splitting, and make wood pulp, titanium dioxide and pigments The mixing is more uniform and the mutual bonding is tighter. The slurry is configured into a slurry with a mass percentage concentration of 5.3%, a tapping degree of 35°SR, and a wet weight of 2.0-2.5g;

[0028] The third step: batching, fur...

Embodiment 3

[0031] Reference figure 1 The production process steps of the high-speed dipping printing decorative base paper of the present invention are as follows:

[0032] The first step: pulping, through the pulping equipment, wood pulp, titanium dioxide, pigments and water are evenly mixed to prepare a slurry with a mass percentage of 6.5%. The required raw materials include 9% by weight Softwood pulp, 65% hardwood pulp, 14% titanium dioxide, 13% kaolin and 3% pigment; the pigment is composed of iron oxide;

[0033] The second step: refining, through the high-speed rotating friction and squeezing of the refining equipment, so that the pulp after pulping can achieve the required cutting and splitting, and make wood pulp, titanium dioxide and pigments The mixing is more uniform and the mutual bonding is tighter. The slurry is configured into a slurry with a mass percentage concentration of 5.8%, a tapping degree of 32°SR, and a wet weight of 2.0-2.5g;

[0034] The third step: batching, furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com