Black chemical oxidation liquid for steel and application of black chemical oxidation liquid

A chemical oxidation and black technology, which is applied in the coating process of metal materials, etc., can solve the problems of high energy consumption, serious human injury, environmental pollution, etc., and achieve the effects of high film forming efficiency, easy operation, and process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

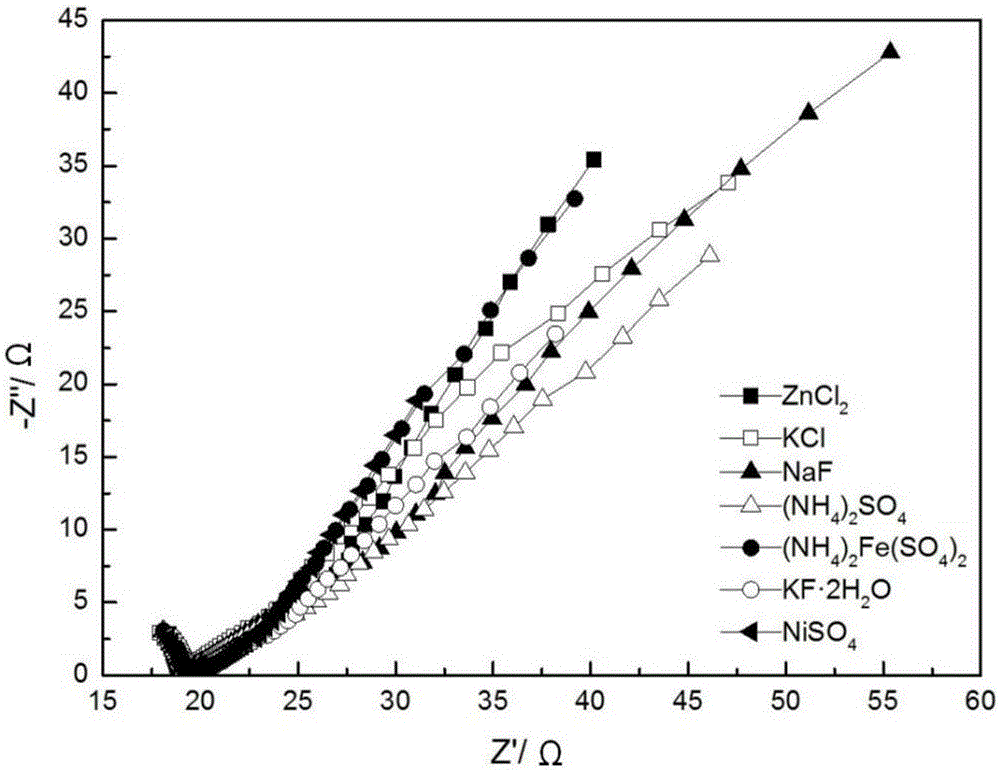

[0025] Examples 1-7: Experiments on black chemical oxidation solutions containing different additives and their blackening effects.

[0026]

[0027]

[0028] In order to determine the optimal components of the additives in the formulation, 7 additives with the same dosage were selected for parallel experiments, and the other components and dosages in the formulation were kept exactly the same. Through the following process flow, 7 kinds of black chemical oxidation solutions were compared and analyzed:

[0029] (1) Preprocessing:

[0030] Pickling and cleaning the surface of the steel sheet to remove rust and oil.

[0031] (2) Black chemical oxidation:

[0032] A) Preparation of oxidizing solution: Accurately weigh according to the amount of each component in the above table, put it in a beaker after weighing, add 200mL of water, stir and dissolve, heat the water bath to 50°C, measure the pH value of the solution (pH=2.5 ~4.6).

[0033] B) Oxidation and film formatio...

Embodiment 8-12

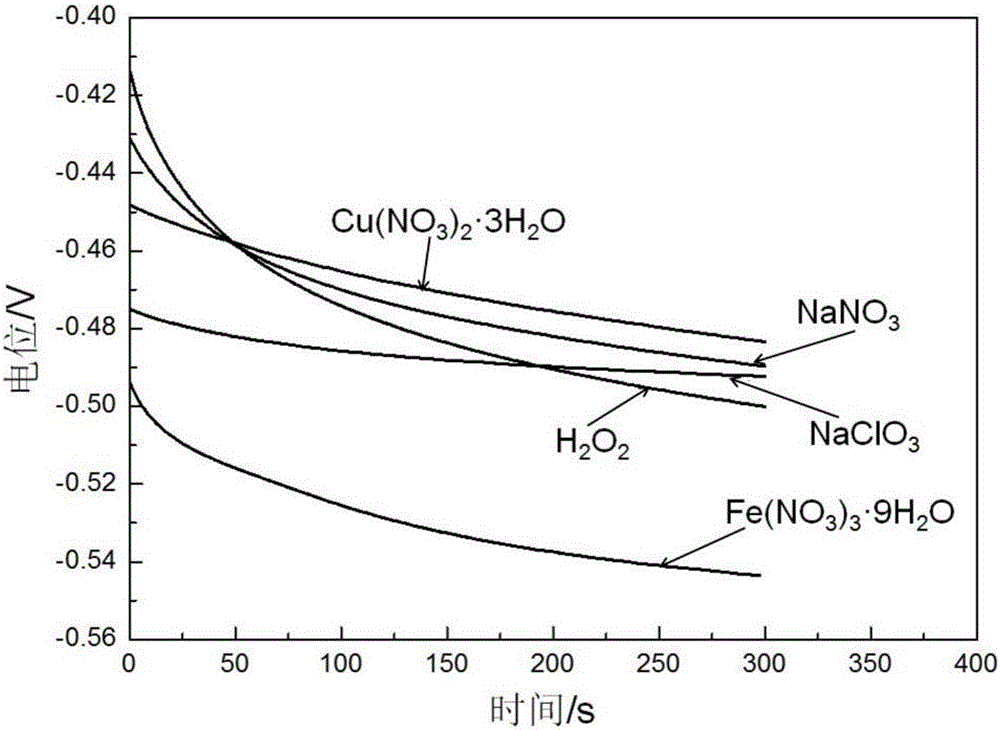

[0035] Examples 8-12: Experiments on black chemical oxidizing solutions containing different oxidants and no reducing agent and their blackening effects.

[0036]

[0037]

[0038] In order to determine the optimal composition of the oxidizing agent in the formulation, under the condition of not adding a reducing agent, five oxidizing agents with the same amount were selected for parallel experiments, and the other components and amounts in the formulation were kept exactly the same. By the technological process described in embodiment 1, measure the open circuit potential-time curve of the black oxide film that generates by 5 kinds of black chemical oxidation liquids in 3.5% (wt) NaCl solution, its result is as follows figure 2 shown.

[0039] Depend on figure 2 It can be seen that the highest open circuit potential is Cu(NO 3 ) 2 ·3H 2 O, its value is -0.4834V; the smallest open circuit potential is Fe(NO 3 ) 3 9H 2 O, its value is -0.5437V. Therefore, when t...

Embodiment 13-17

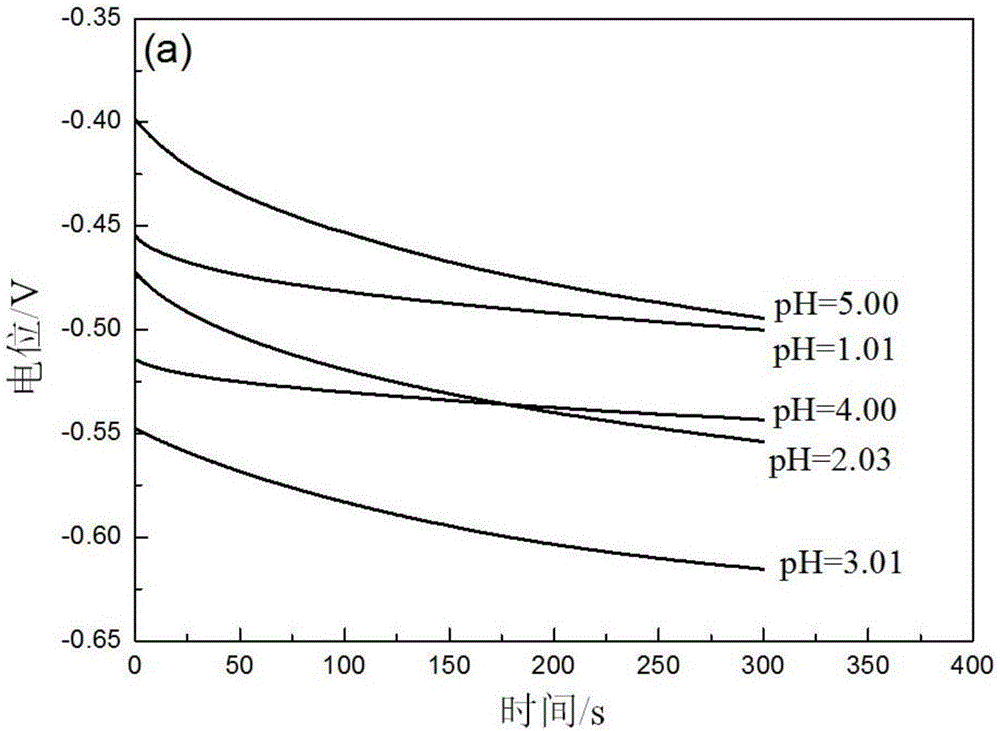

[0040] Examples 13-17: Experiments on black chemical oxidation solutions with different pH values and their blackening effects.

[0041]

[0042] In order to investigate the influence of pH value on the performance of black oxide film, the pH value of the oxidation solution was adjusted (the range of pH value is 1-5), and the other components and dosages in the formula were kept completely consistent. By the technological process described in embodiment 1, measure the corrosion resistance of the black oxide film that is generated by 5 kinds of black chemical oxidation liquids, its result is as follows image 3 shown.

[0043] Depend on image 3 It can be seen that when the pH value rises from 3.01 to 5.00, the open circuit potential increases accordingly. When pH=5.00, the open circuit potential is the largest, which is -0.4944V, and when pH=3.01, the open circuit potential is the smallest, which is -0.6154V. However, when the pH value increased from 1.00 to 3.01, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com