Novel polymer based microfluid reactor suitable for photochemistry reaction and preparation method thereof

A technology of microfluidic reactors and photochemical reactions, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as failure to top, high cost of capping materials, and light transmission. To achieve the effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

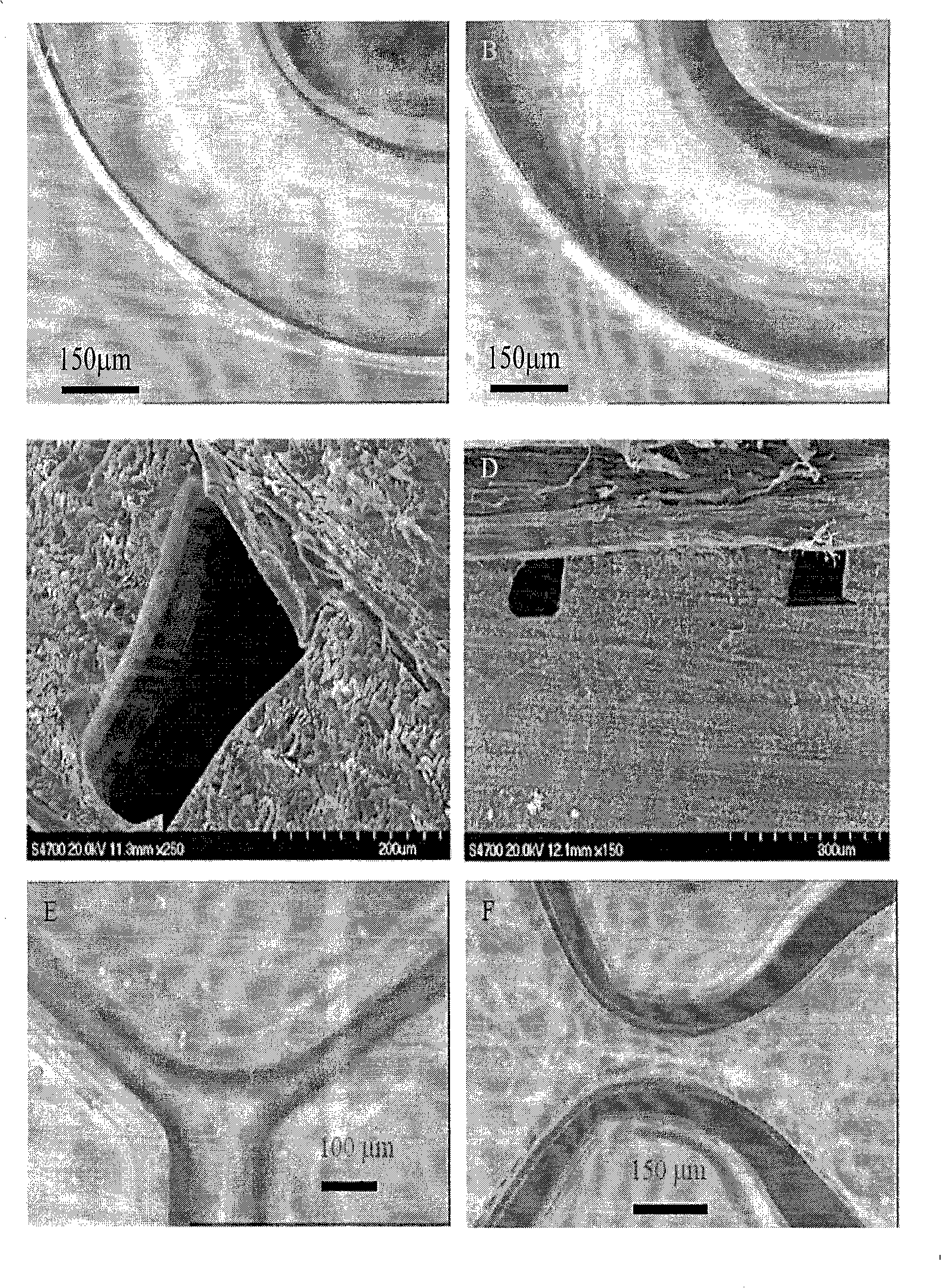

[0032] 3. Preparation of Microfluidic Reactor

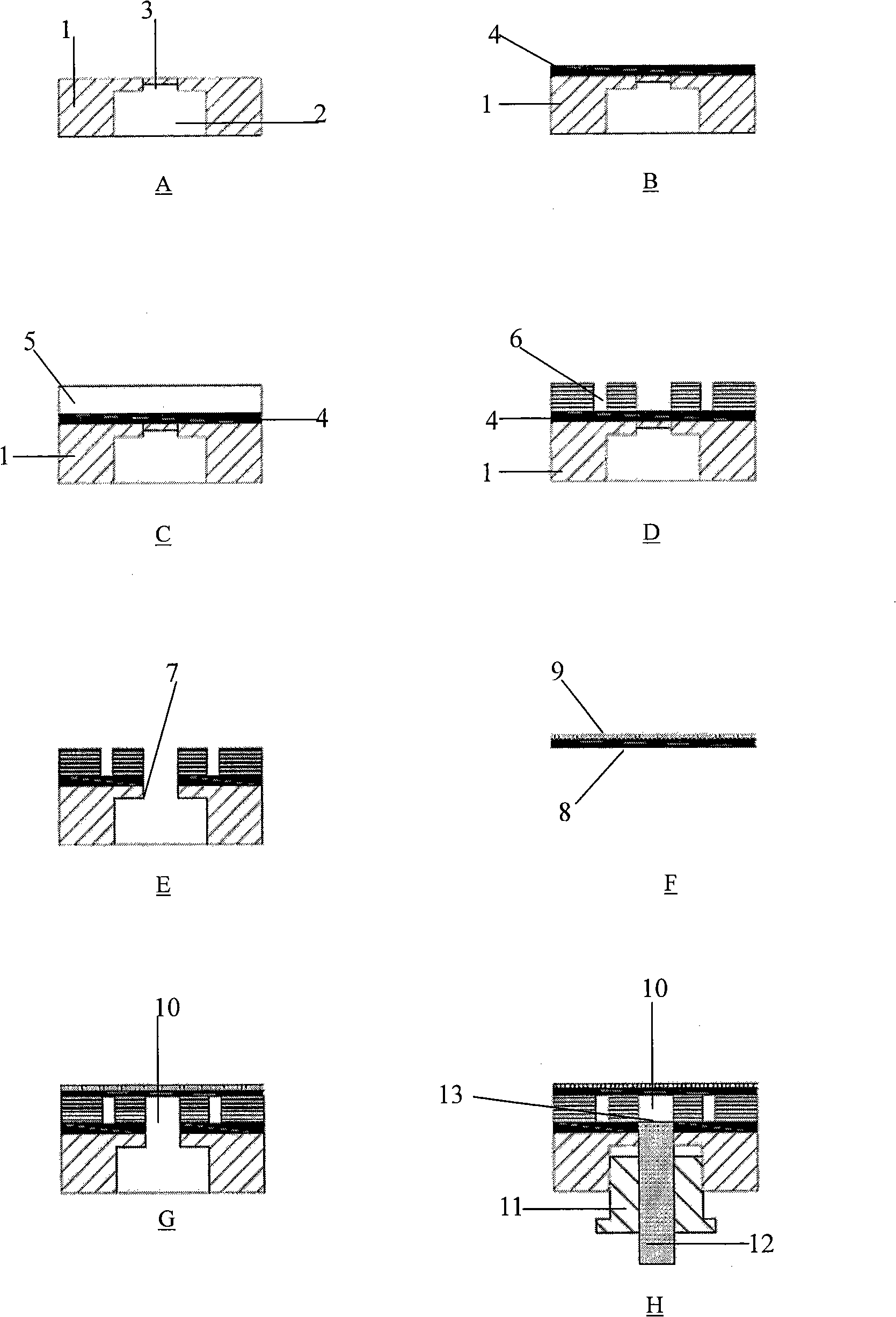

[0033] The construction of the flow channel of the microfluidic reactor adopts photolithography process, and the schematic diagram of the process flow is shown in figure 1 .

[0034] Threaded holes 2 (only one is shown in the figure) are machined at the inlet and outlet positions (bottom) of the PMMA substrate 1. In order to facilitate the spin-coating of the adhesive layer, all inlets and outlets 3 are not opened. figure 1 As shown in A.

[0035] Use EA51 to modify the surface of PMMA matrix 1, such as figure 1 Shown in B.

[0036] Next, spin-coat SU82050 on the surface of EA51 cured adhesive layer 4 to form adhesive layer 5, such as figure 1 C shown. And carry out the three-step process of pre-baking, exposure and post-baking.

[0037] Then, if figure 1 As shown in D, the unexposed part is developed to form the micro channel pattern 6 .

[0038] Then all the imports and exports 7 can be opened up (only one is shown in t...

example 1

[0063] Example 1 prepares the microreactor of polymer microsphere

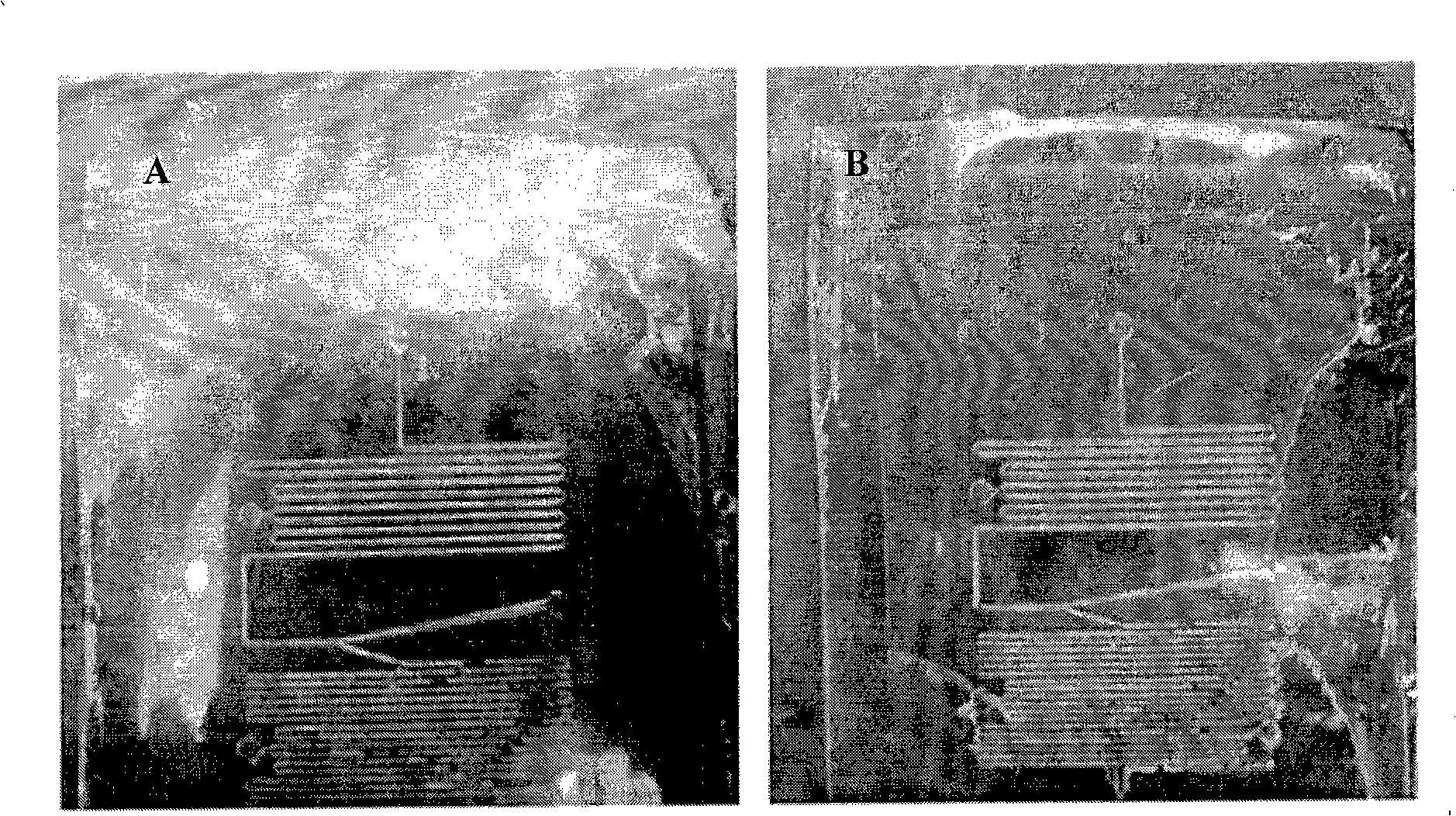

[0064] Figure 8It is a microfluidic reactor for preparing polymer microspheres (surface functionalization, core-shell structure and other particles). The preparation process of the reactor is as described above. In order to slow down the pressure increase and facilitate the flow of liquid into and out of the microchannel, the inlet and outlet channels of the microfluidic reactor are all designed with a gradually changing width.

[0065] Such as Figure 8 As shown, the polymer microsphere microreactor has three inlet channels 14, 15 and one outlet channel 16, and each terminal has an inlet (outlet) hole 17 with a diameter of 1 mm (only one is marked in the figure). The dispersed phase (such as the oily monomer phase) flows in through the inlet channel 14 in the middle, and the continuous phase (such as the water phase) flows in through the inlet channels 15 on both sides. When the three microfluids pass th...

example 2

[0066] Example 2 prepares the microreactor of nanoparticle

[0067] Figure 9 It is a microfluidic reactor for the preparation of nanoparticles (such as Au, Ag, Co). The preparation process of the reactor is as described above. In order to slow down the pressure increase and facilitate the flow of liquid into and out of the microchannel, the inlet and outlet channels of the microfluidic reactor are all designed with a gradually changing width.

[0068] Such as Figure 9 As shown, the nanoparticle microreactor has three inlet channels 20, 21 and an outlet channel 22, wherein 20 is the first inlet channel, 21 is the second inlet channel, and the terminals of all the inlet and outlet channels have an inlet with a diameter of 1 mm. (Export) hole 23 (only one is marked among the figure). We can add a new reactant to the second inlet 21 to make it mix with the previous microfluidic reaction solution for reaction. The two passages of the first inlet 20 can add different reactant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com