Solvent-free preparation method of 1, 4-DMCD

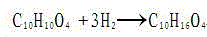

A technology of dimethyl cyclohexanedicarboxylate and dimethyl phthalate, which is applied in the field of catalytic hydrogenation preparation 1, can solve the problems of cumbersome treatment process, low yield, increased cost of solvent recovery, etc., and achieve optimized process, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Put 2t of DMCD into the mixing tank, add 0.9t of DMT, heat and stir, after it is completely dissolved, feed the material to the fixed bed of the first hydrogenation reaction at a flow rate of 200kg / h through a metering pump, control the temperature at 140°C, and the pressure at 4.0MPa , The detection reaction conversion rate was 99.7%, and the selectivity was 99.5%.

Embodiment 2

[0012] Put 2t of DMCD into the mixing tank, add 0.9t of DMT, heat and stir, after it is completely dissolved, feed the material to the fixed bed of the first hydrogenation reaction at a flow rate of 250kg / h through a metering pump, control the temperature at 140°C, and the pressure at 4.0MPa , The detection reaction conversion rate was 99.4%, and the selectivity was 99.2%.

Embodiment 3

[0014] Put 2t of DMCD into the mixing tank, add 0.9t of DMT, heat and stir, after being completely dissolved, feed the material to the fixed bed of the first hydrogenation reaction at a flow rate of 300kg / h through a metering pump, control the temperature at 140°C, and the pressure at 4.0MPa , The detection reaction conversion rate was 99.0%, and the selectivity was 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com