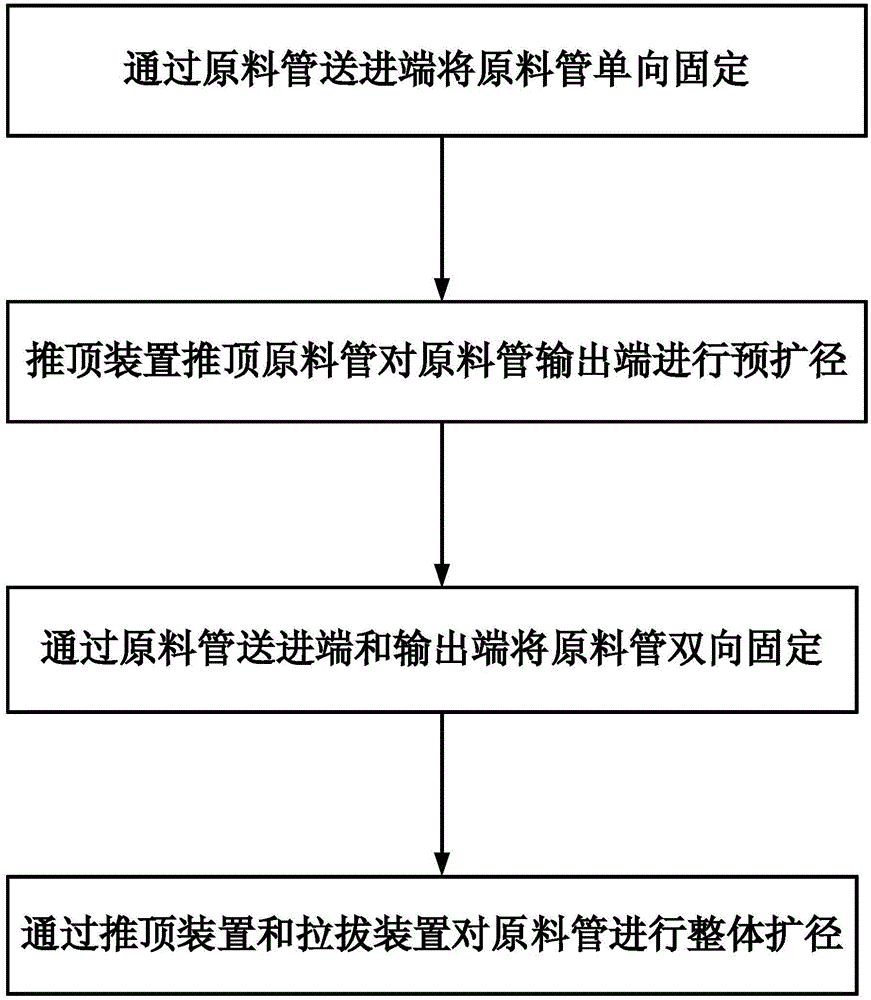

Method for producing variable-thickness variable-diameter steel pipes

A technology of variable diameter and thickness, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of expansion of original defects, slow production speed of single machine, uncontrollable wall thickness, etc., to improve process production efficiency and reduce process Loss, the effect of reducing the expansion cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

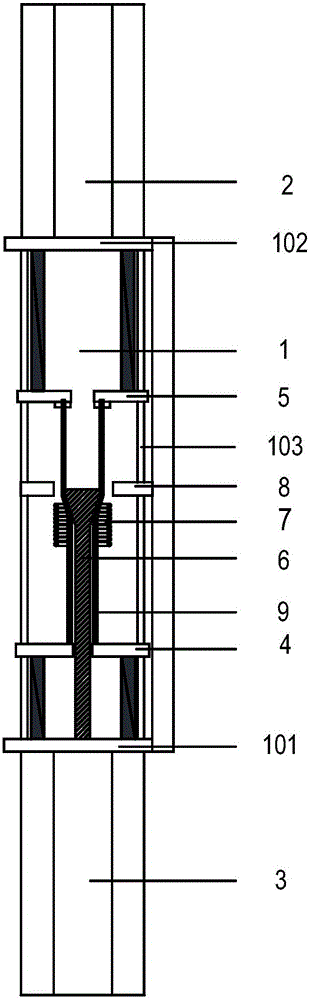

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

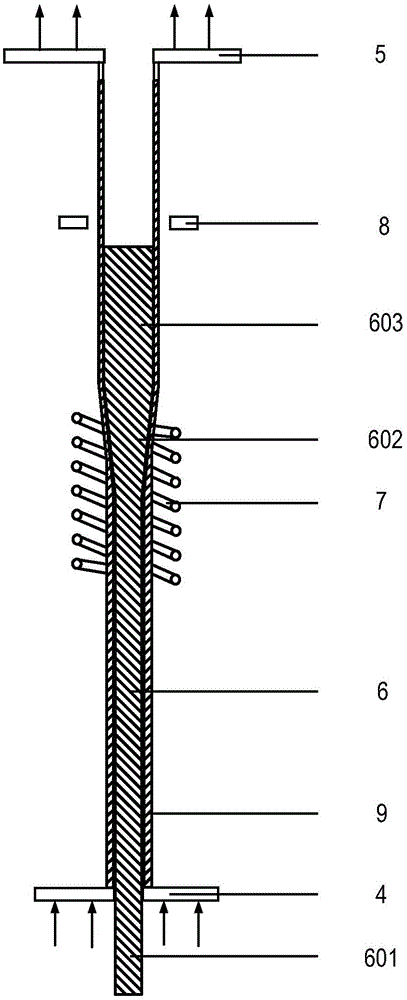

[0034] Such as figure 2 As shown, in the method for producing steel pipes with variable thickness and variable diameter according to the present invention, the pipe expanding machine used in the method includes a frame 1 with a guide rod group 103 arranged between the push top end 101 and the pull end 102, and the frame 1 pushes The pushing device 3 at the top 101 and the pulling device 2 arranged at the pulling end 102 of the frame 1 slide sequentially along the direction from the pushing top 101 to the pulling end 102 to cooperate with the steel pipe feeding end arranged on the guide rod group 103 Fixed plate 4, fixed plate 5 at the output end of the steel pipe, a diameter-expanding plug 6 with a guide section 601, a variable diameter section 602, and a fixed diameter section 603; The working end of the device 2 is fixedly connected to the fixed pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com