Pipe expanding machine for producing variable thickness steel pipe

A technology of variable thickness and pipe expanding machine, applied in metal processing equipment, feeding device, positioning device, etc., can solve the problems of short length of large-diameter seamless steel pipe, uneven surface of steel pipe, large equipment investment, etc., to improve the process Production efficiency, less equipment involved in the process, and the effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

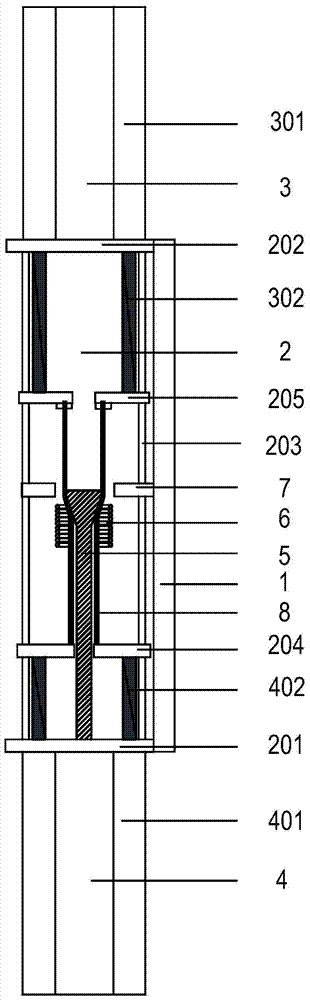

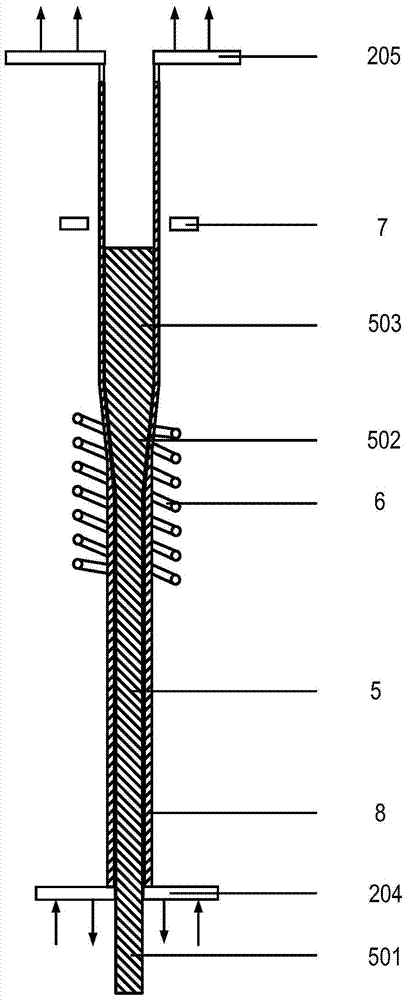

[0036] like figure 1 , figure 2 As shown, the pipe expanding machine for producing variable thickness steel pipes of the present invention includes a frame 2 fixed on a base 1, a diameter expanding plug 5 with a guide section 501, a variable diameter section 502, and a fixed diameter section 503 for heating The heating device 6 of the steel pipe 8 also includes a pushing device 4 arranged at the top of the frame, and a drawing device 3 arranged at the drawing end of the frame; Pulling end support plate 202, the two ends are respectively fixedly connected to the guide rod group 203 on the pushing top support plate 201 and the drawing end support plate 202, and are sequentially set along the direction from pushing top end support plate 201 to drawing end support plate 202 The steel pipe feeding end fixed plate 204 and the steel pipe output end fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com