Multifunctional variable integral hoisting template system

An overall lifting and multi-functional technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the difficulty in adjusting the formwork and hanger, the consumption of the construction period, the labor intensity on the site, etc. problems, to achieve the effect of reducing technical intermittent time, saving jacking force, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

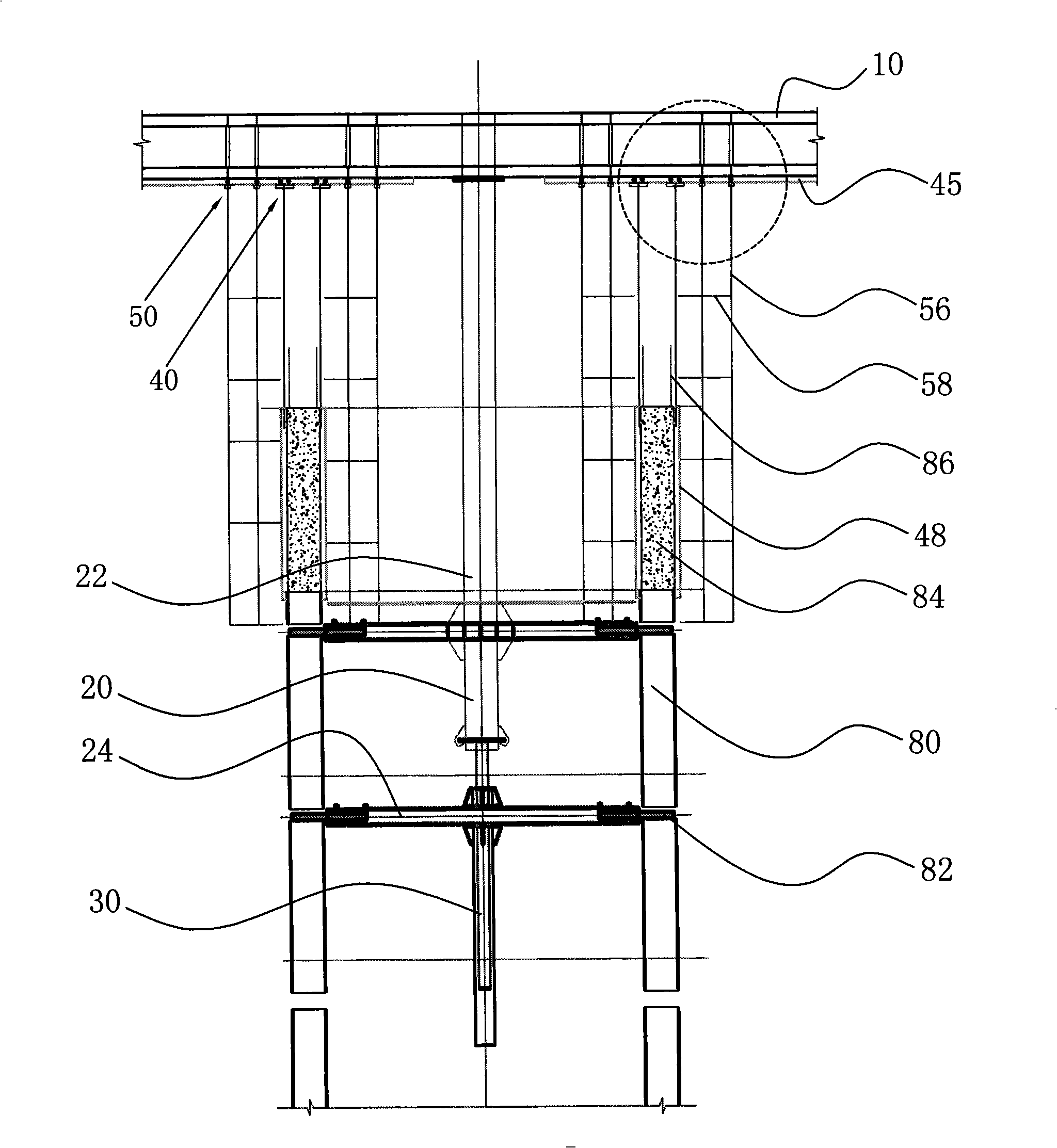

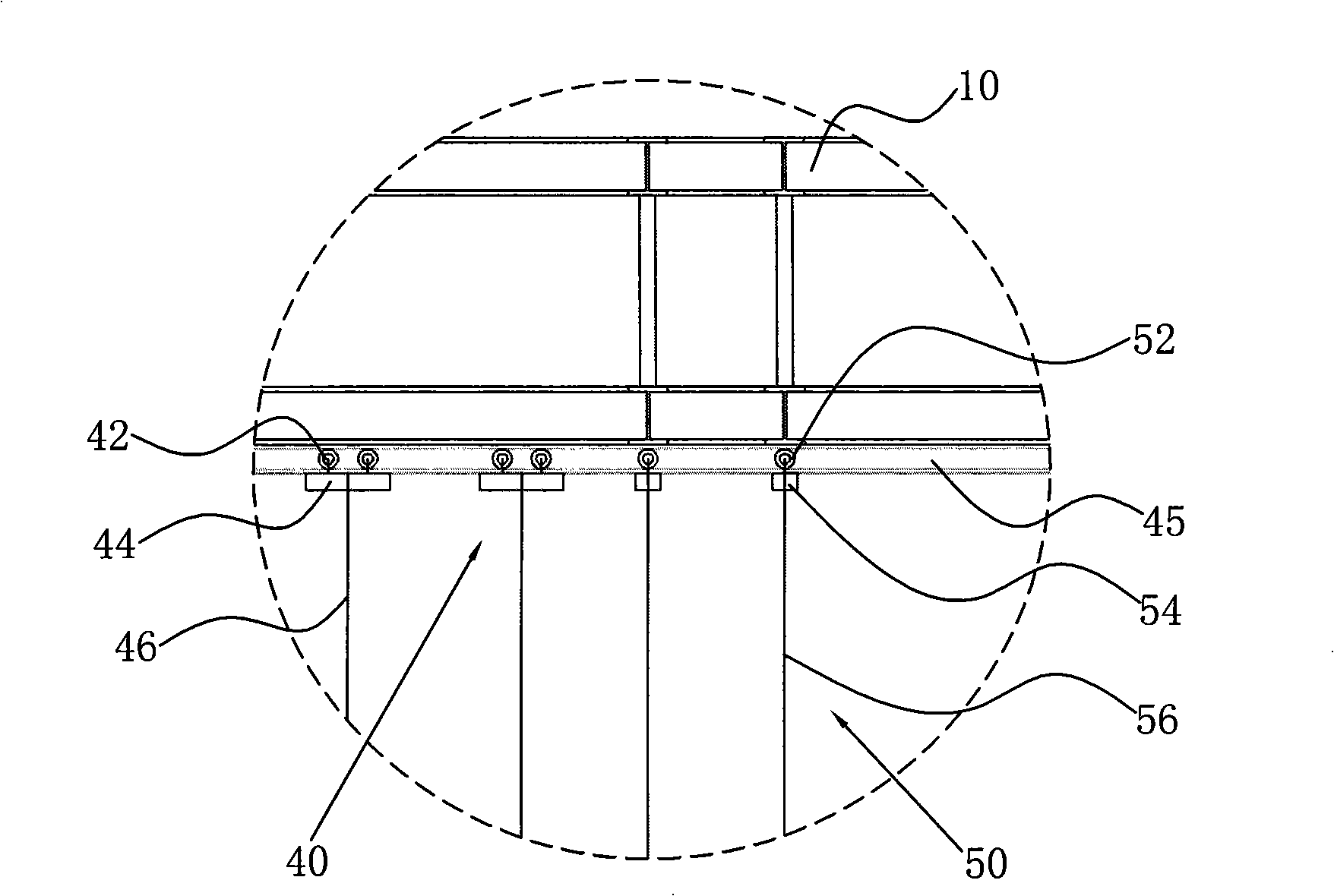

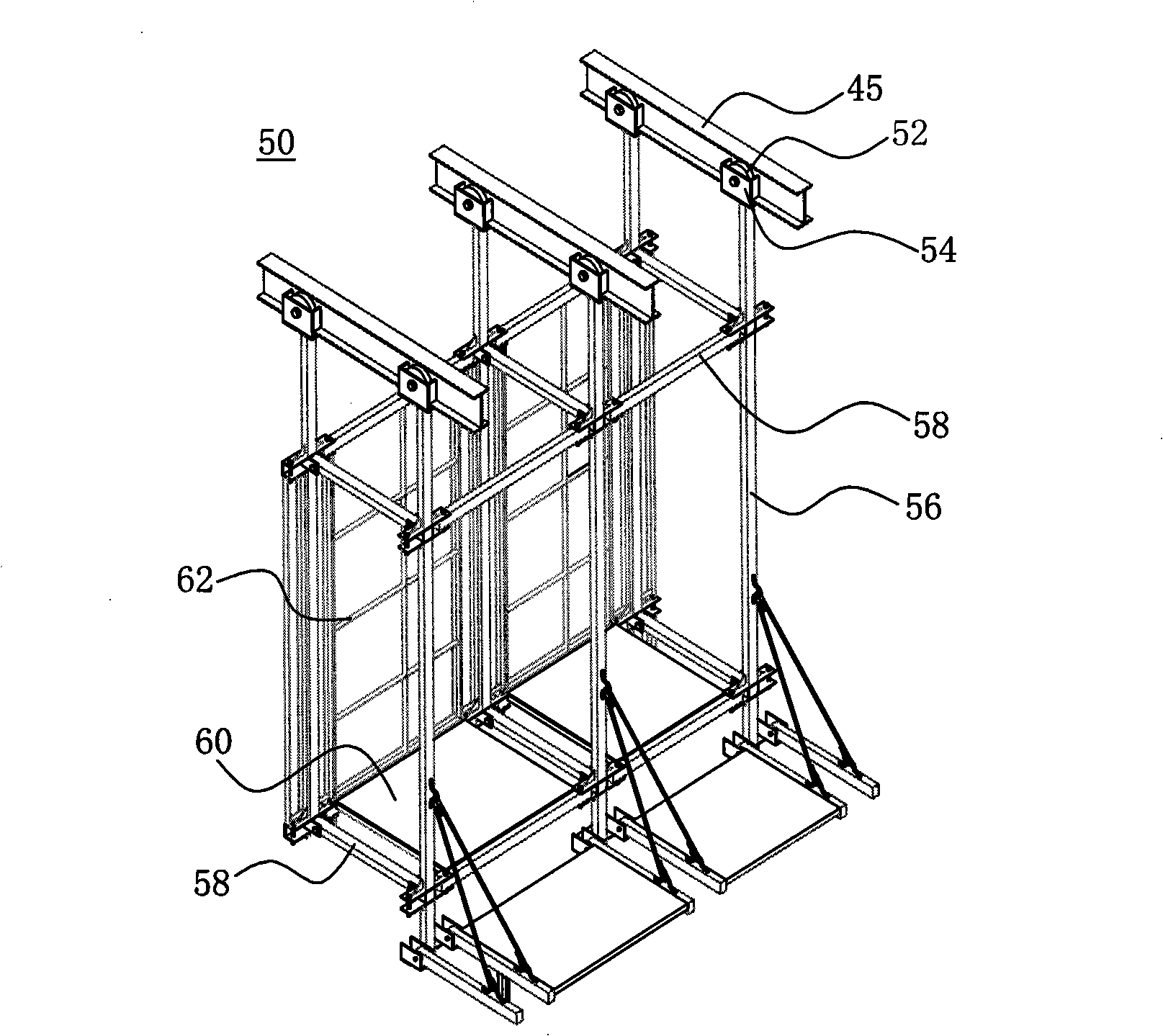

[0023] The present invention is a multifunctional and variable overall lifting formwork system for high-rise building construction, which is arranged on the top of the building structure wall to be constructed, such as figure 1 As shown, it includes a platform main frame 10, a hanger subsystem 50 hung on the platform main frame, a formwork subsystem 40 hung on the platform main frame, at least three walls supported on the building And support the support subsystem 20 of the platform main frame, which is arranged in the support subsystem to promote the platform main frame, the hanger subsystem and the template subsystem to rise synchronously and adjust the balance of the platform main frame The power and control subsystem 30.

[0024] Better yet, refer to Figure 4 , Figure 5 , the platform main frame 10 is a three-dimensional platform formed by fixed connection of several trusses 12 . A truss is a planar or space structure generally having a triangular unit composed of str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com