Automatic belt maker

An automatic belt-making and belt-passing technology, which is applied in metal processing and other directions, to achieve the effects of convenient storage, elimination of safety hazards, and easy binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

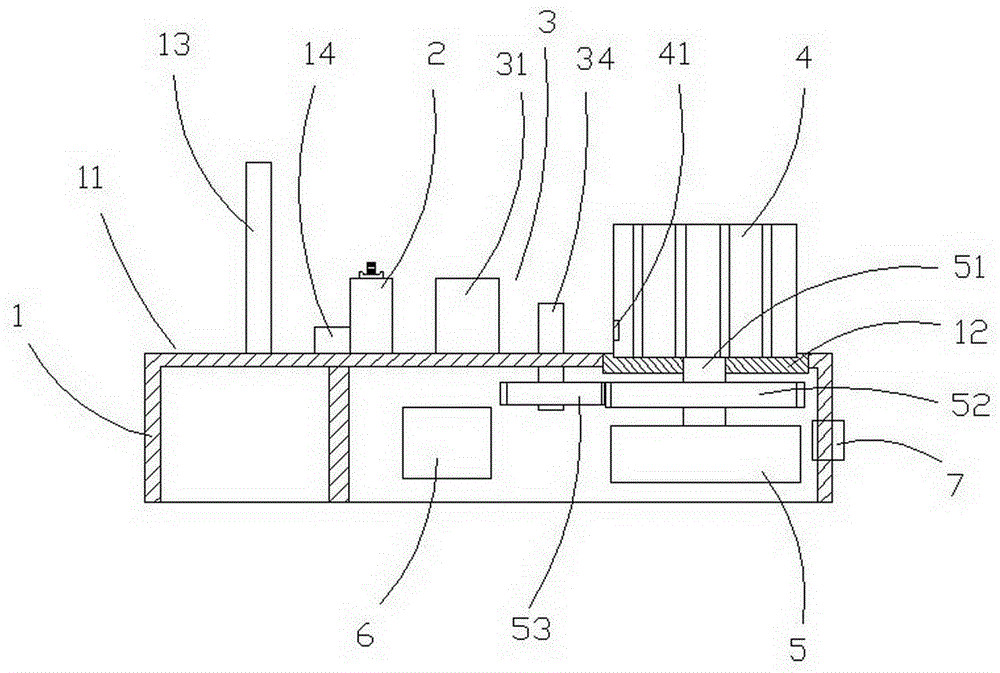

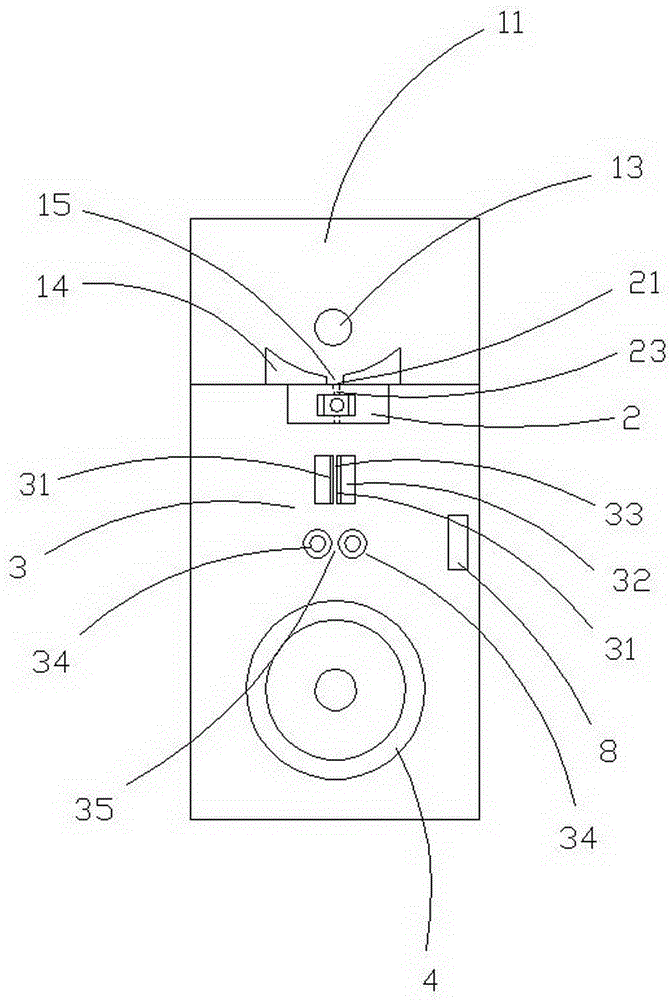

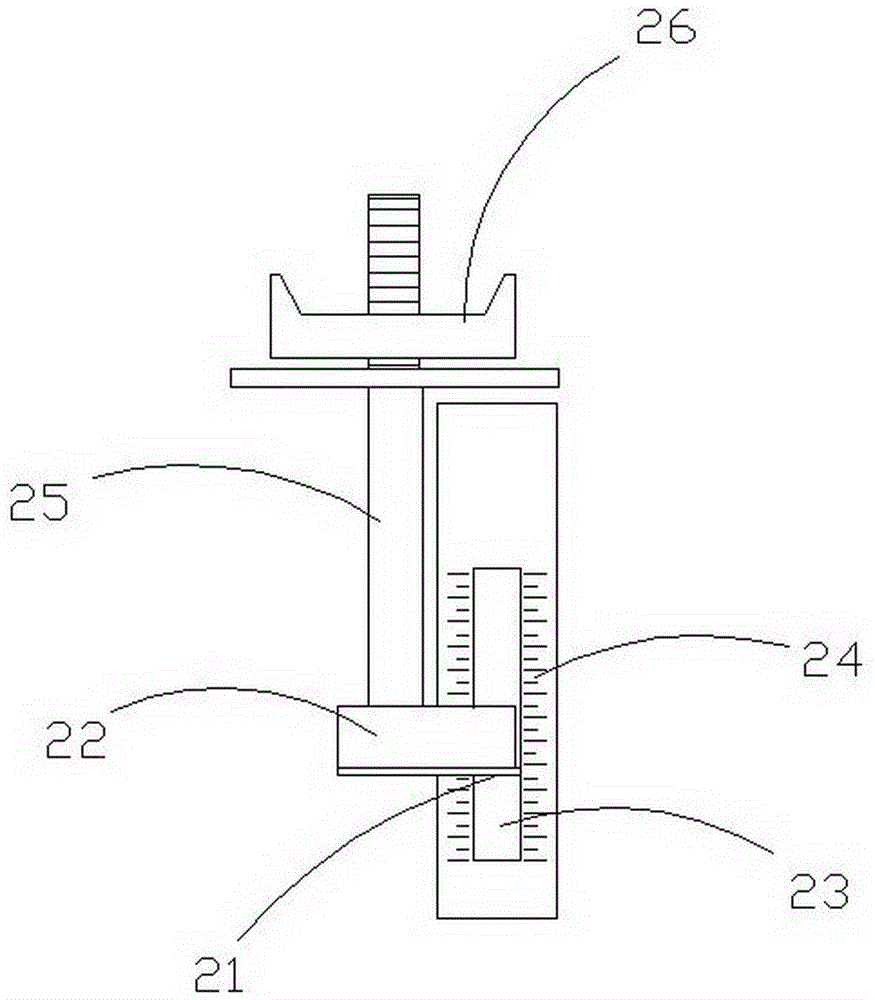

[0017] Such as figure 1 , 2 As shown, an automatic belt maker includes an outer casing 1, a cutting device 2, a leveling device 3, and a winding roller shaft 4. The platform 11 of the outer casing 1 is provided with a vertical positioning column 13, and an arc baffle The inside of the center gap 15 of 14 is provided with a cutting device 2, and a movable blade 21 is provided on the belt passing groove 23 of the cutting device 2, and the blade seat 22 is connected with an adjustment rod 25, and the adjustment rod 25 is externally connected with a locker 26. The belt passing guide 33 between the two electric heating plates 31 of the leveling device 3 and the nip 35 between the two rolling shafts 34 and the belt passing groove 23 of the cutting device 2 are respectively arranged correspondingly and on the same straight line, and are arranged on the outer shell 1 The upper part of the motor 5 in the inner cavity protrudes from the support plate 12 and is connected with the windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com