Reinforced sack grouting stone-breaking pile with heat transferring tube buried therein and construction method

A construction method and technology of heat transfer tubes, which are applied in the field of ground source heat pumps, can solve the problems of low strength, easily damaged heat transfer tubes, and large compression deformation, so as to enhance the integrity of piles, facilitate placement and binding, improve strength and Effect of Composite Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

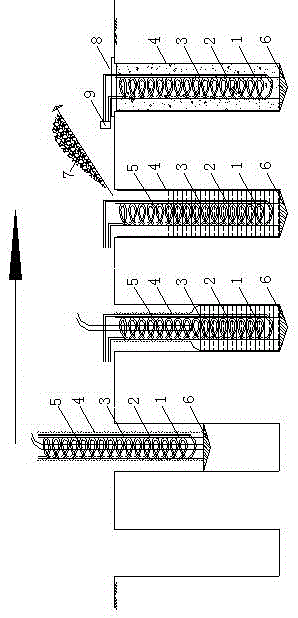

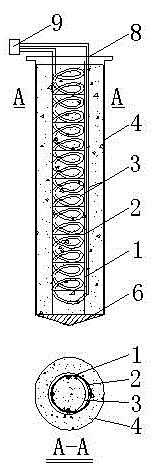

[0029] like Figure 1-2 As shown, a reinforced cement crushed stone cloth bag pile with heat transfer tubes buried in figure 1 , figure 2 Among them, the longitudinal reinforcement 1 and the horizontal stirrup 2 are bound to form a reinforcement cage, and the heat transfer pipe 3 is bound outside the reinforcement cage, and the buried pipe is fixed in design, and the geotextile bag 4 is closely attached to the outside of the heat transfer pipe on the outside, and the grouting pipe 5 is placed Inside the reinforcement cage, the bottom is open to the upper part of the prefabricated pile tip 6, and the bottom of the longitudinal reinforcement 1 is prefabricated with the prefabricated pile tip 6, and at the same time, the geotextile bag 4 is embedded in the prefabricated pile tip to prevent grout from running out during grouting; after the hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com