Multifunctional reel-type sprinkling machine

A reel-type, sprinkler irrigation technology, applied in horticulture, botanical equipment and methods, cultivation and other directions, can solve the problems of troublesome operation, troublesome installation and disassembly, reduced return speed, etc., and achieves the effect of convenient bundling and prevention of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

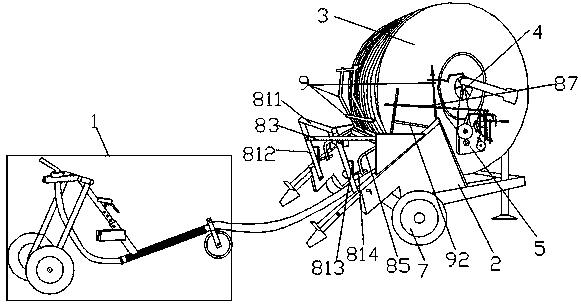

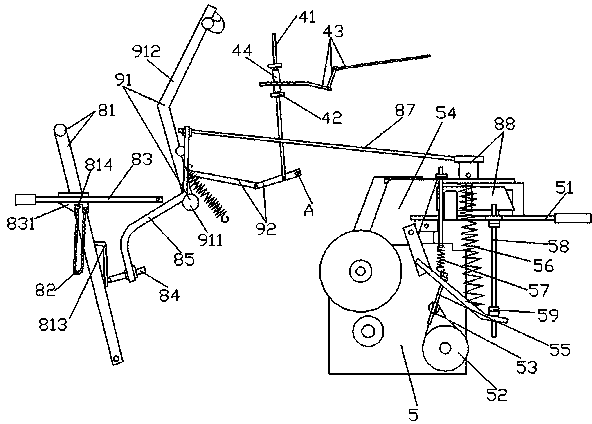

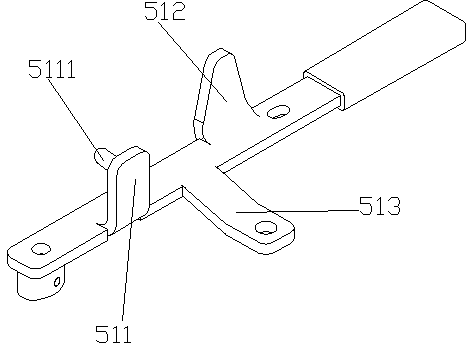

[0032] Such as Figures 1 to 9 As shown, an embodiment of the present invention comprises water jet vehicle 1, frame 2 and reel 3 that is arranged on frame 2, water turbine 4, gearbox 5, pipe arrangement 6 and road wheel 7, and it also includes The carriage return stop linkage device 8 and the water turbine automatic speed control device 9, the gearbox 5 are provided with a manual shift lever 51 and a brake wheel 52, and the brake wheel 52 is provided with a brake band 53. The water turbine 4 is provided with a manual speed regulating device connected with a regulating valve, and the manual speed regulating device includes a threaded rod 41 and a speed regulating knob 42 arranged on the threaded rod 41 . The water turbine 4 is connected to the gearbox 5 through a transmission belt, and the output end of the gearbox 5 is connected to the chain plate on one side of the reel 3 through a transmission chain, and the water turbine 4 drives the gears in the gearbox 5 to rotate. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com