Braking method for belt conveyor

A technology of belt conveyor and brake block, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of expensive, complicated structure, time-consuming and laborious, and achieve the effect of expanding the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

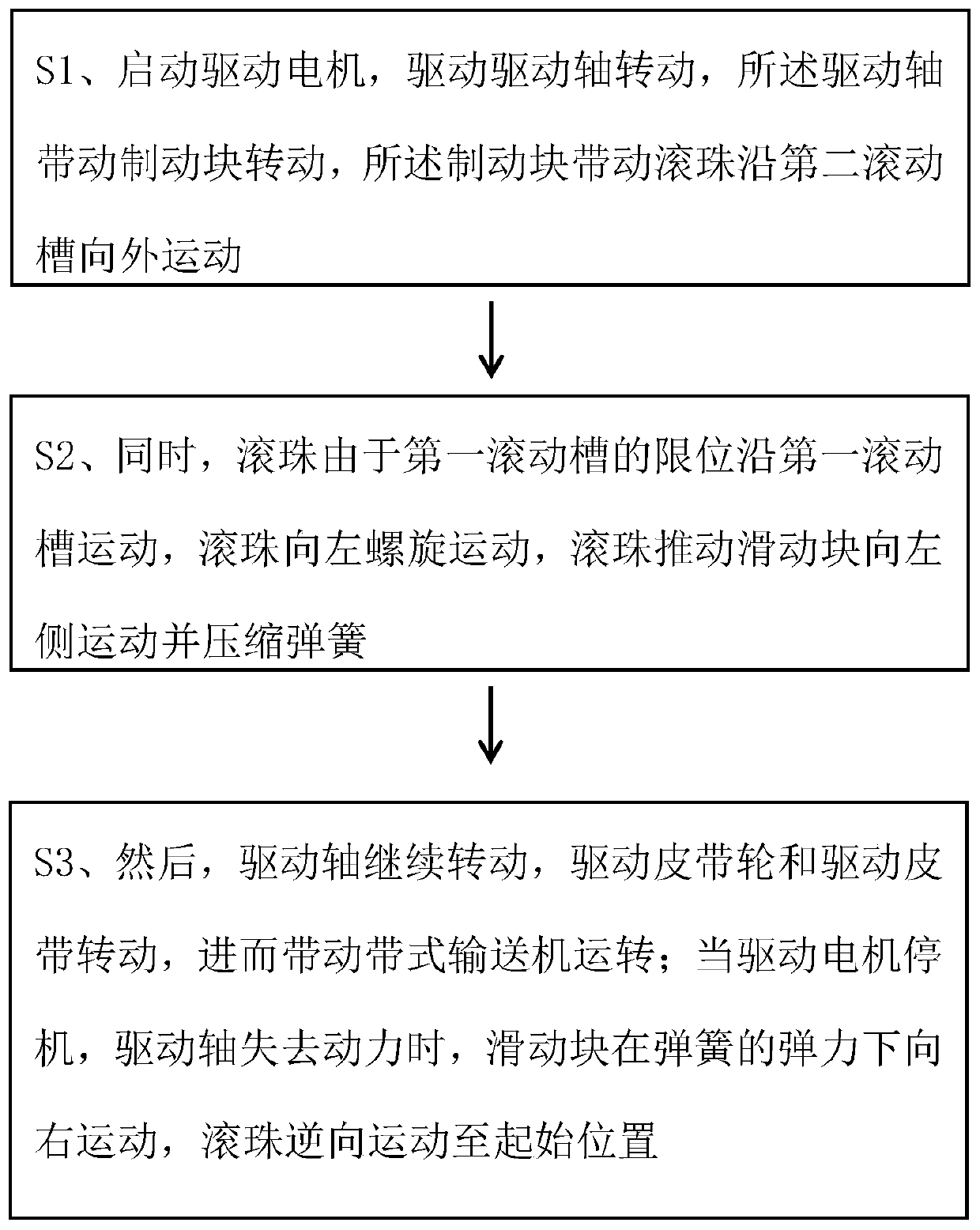

[0031] A braking method for a belt conveyor, comprising the steps of:

[0032] S1. Start the drive motor to drive the drive shaft to rotate, the drive shaft drives the brake block to rotate, and the brake block drives the balls to move outward along the second rolling groove.

[0033] S2. At the same time, due to the limit of the first rolling groove, the ball moves along the first rolling groove, the ball spirally moves to the left, and the ball pushes the sliding block to move to the left and compresses the spring.

[0034] S3. Then, the drive shaft continues to rotate, the drive pulley and the drive belt rotate, and then drives the belt conveyor to run; when the drive motor stops and the drive shaft loses power, the sliding block moves to the right under the elastic force of the spring, and the ball moves in reverse to starting point.

[0035] The step S2 also includes: when the ball moves to the end of the first rolling groove and the second rolling groove, the sliding ke...

Embodiment 2

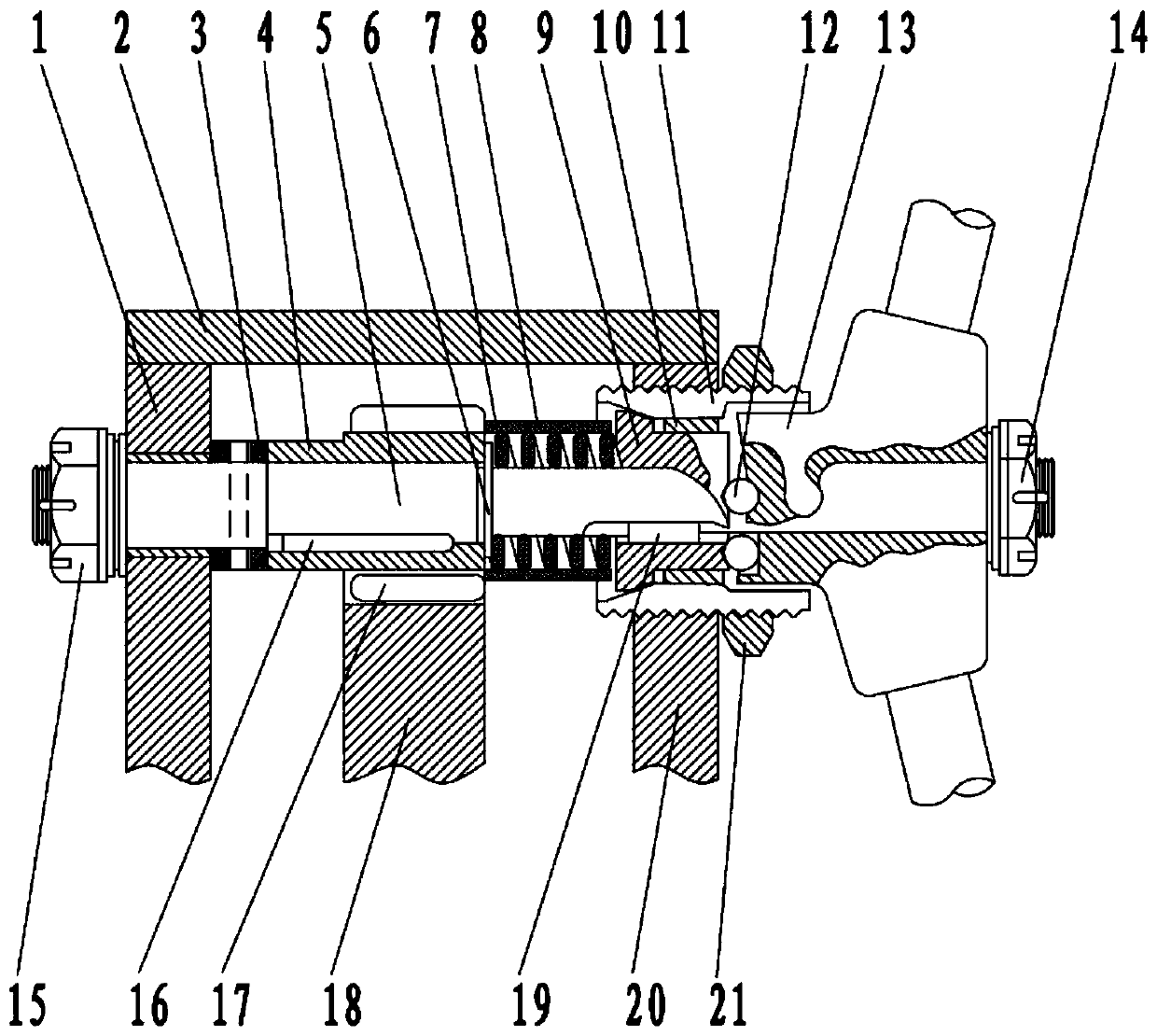

[0039] Such as Figure 2-4 As shown, a braking device for a belt conveyor includes: a drive shaft 5, which is used to drive a pulley 17, and then drives a belt conveyor; a sliding block 9, which is used for braking the drive shaft 5; The structure is used to control the sliding block 9 to move between the braking position and the non-braking position.

[0040] The left end of the drive shaft 5 is rotated on the first support 1 through a bearing, and the left end of the drive shaft 5 is limited in the axial direction by the first fastening nut 15 and the limit sleeve 3. The right side of the shaft sleeve 3 is abutted against a transmission shaft sleeve 4 .

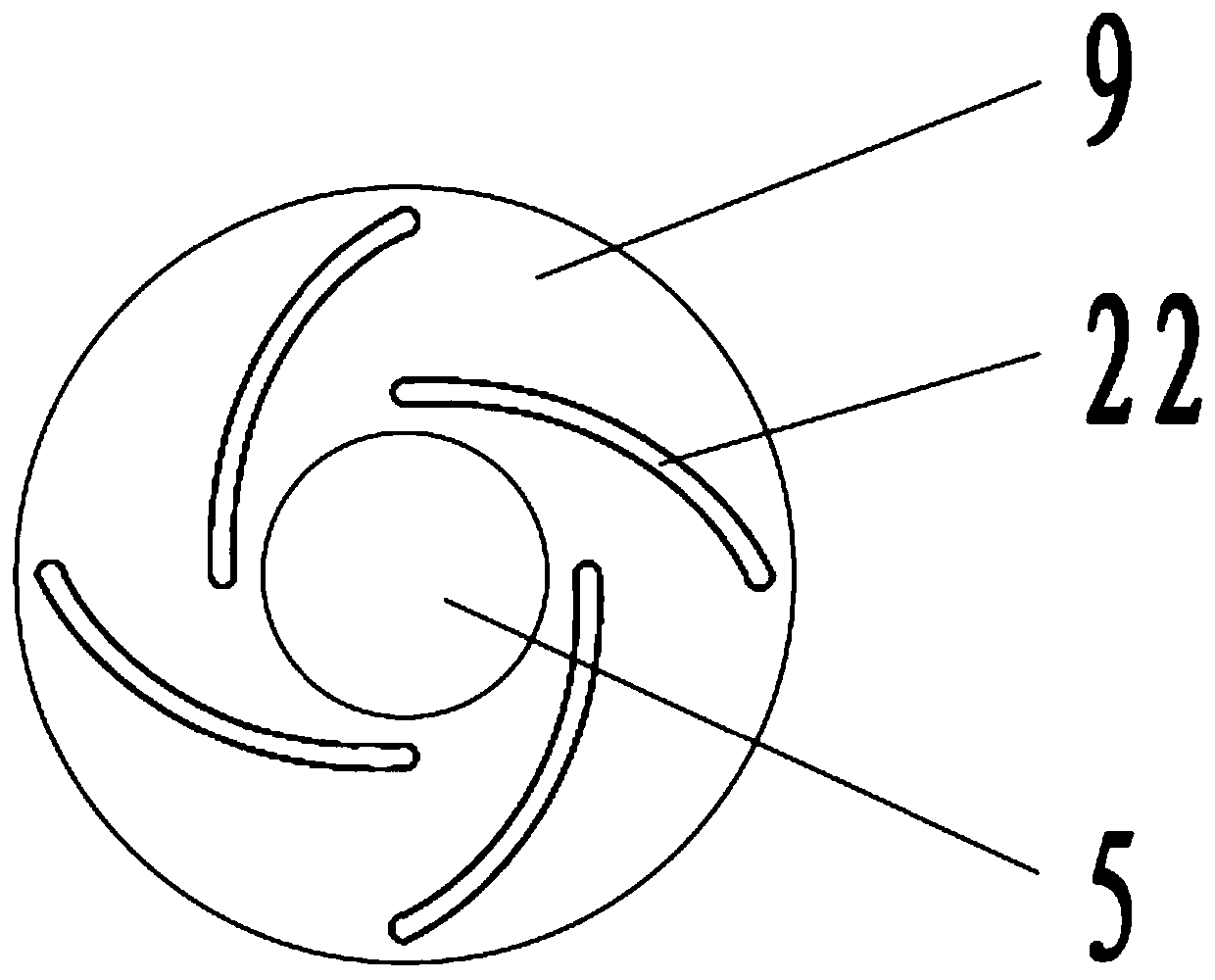

[0041] The brake structure includes a spring washer 6, a spring 7, a sliding block 9, a brake sleeve 11, a ball 12 and a brake block 13, and the spring washer 6 is arranged on the right side of the transmission sleeve 4, The right side of the spring washer 6 abuts against a spring 7, the right side of the spring 7 abuts a...

Embodiment 3

[0051] Such as Figure 2-4 As shown, a braking device for a belt conveyor includes: a drive shaft 5, which is used to drive a pulley 17, and then drives a belt conveyor; a sliding block 9, which is used for braking the drive shaft 5; The structure is used to control the sliding block 9 to move between the braking position and the non-braking position.

[0052] The left end of the drive shaft 5 is rotated on the first support 1 through a bearing, and the left end of the drive shaft 5 is limited in the axial direction by the first fastening nut 15 and the limit sleeve 3. The right side of the shaft sleeve 3 is abutted against a transmission shaft sleeve 4 .

[0053] The brake structure includes a spring washer 6, a spring 7, a sliding block 9, a brake sleeve 11, a ball 12 and a brake block 13, and the spring washer 6 is arranged on the right side of the transmission sleeve 4, The right side of the spring washer 6 abuts against a spring 7, the right side of the spring 7 abuts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com