Clamping and transporting method for aerated concrete blocks

A technology of aerated concrete and blocks, applied in the direction of transportation and packaging, conveyor objects, packaging, etc., can solve the problems of occupation, brick damage, large labor, etc., and achieve the effect of improving stability, improving efficiency, and facilitating bundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] As shown in the figure, a method for clamping and transporting aerated concrete blocks includes the following steps:

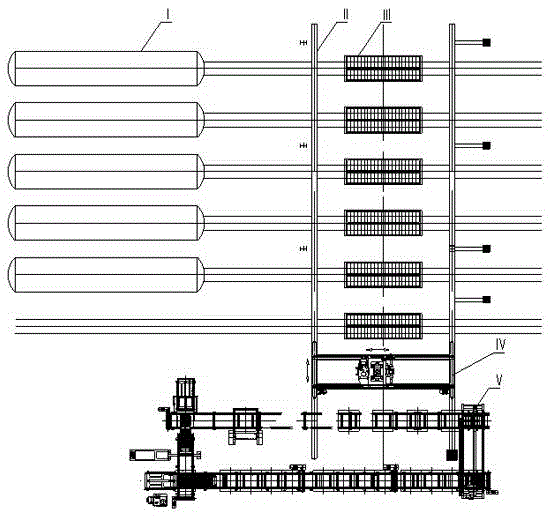

[0030] 1) Push 5 aerated concrete block mold vehicles III arranged side by side (this number is not limited, and it can be the rest) from the autoclave I and position them on the exit track;

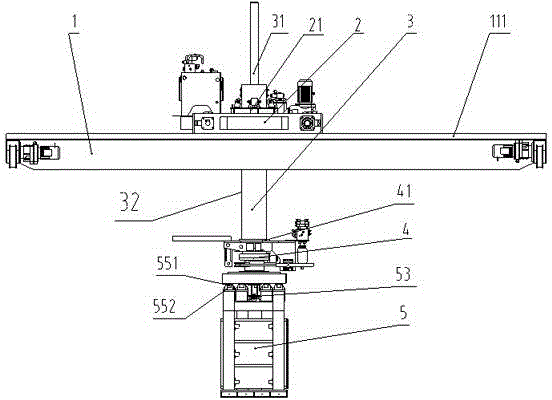

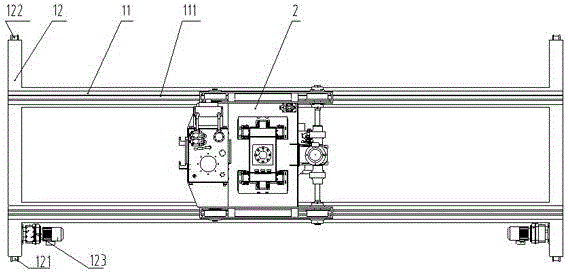

[0031] 2) Use the clamping device IV to move horizontally and vertically to position above the mold car III, and then the clamping device IV clamps 6 layers from the mold car III by moving downward and pinching (This embodiment is 6 layers, the number of layers to be clamped can be selected according to the actual application) aerated concrete block;

[0032] 3) The pinching device IV moves upwards, and then moves horizontally and vertically again to transport the aerated concrete blocks to the top of the packaging unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com