Three-dimensional modular wiring and detection integrated device for wire harness manufacturing

A modular, wire harness technology, applied in the manufacture of wire harnesses, cable/conductor manufacturing, electrical components, etc., can solve the problems of poor versatility and large bundling errors of two-dimensional wiring, so as to facilitate bundling, improve utilization, and reduce costs. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

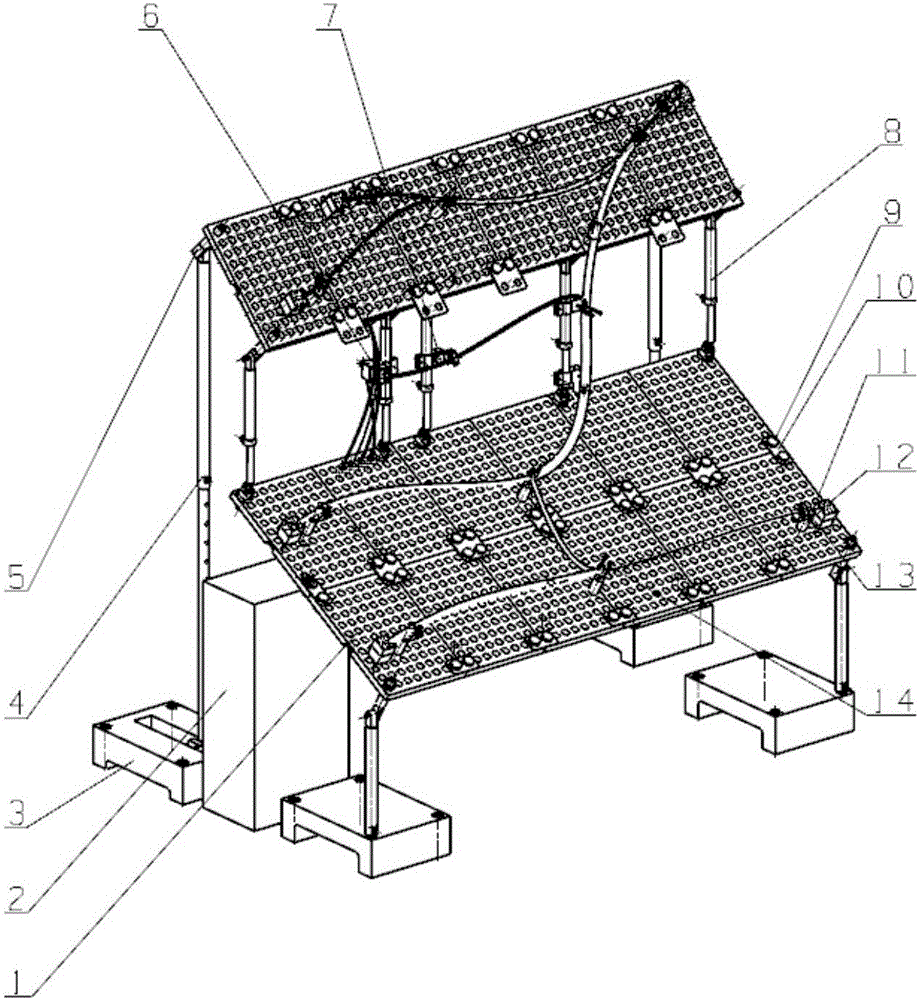

[0070] Such as Figure 1-3 shown.

[0071] A three-dimensional modularized wiring and detection integrated device for wire harness manufacturing, which mainly includes: two wiring board tooling for wire harness manufacturing, an angle adjustment mechanism, a positioning seat 11 for fixing wire harnesses and a binding belt 13, U-shaped fork element 14 for guidance, connector 6 for wire harness inspection and cabinet 2 for wire harness inspection, such as figure 1 , 2 As shown, there is a vertical drop between the upper and lower wiring board fixtures, and the upper and lower wiring board fixtures extend the wiring in space, as shown in figure 1 Shown; One side of the wiring board tooling of the lower part and the wiring board tooling of the upper part are all installed on the corresponding angle adjustment mechanism, and the wiring board tooling of the lower part and the other side of the wiring board tooling of the upper part are connected by a rotatable telescopic link 8. ...

example 2

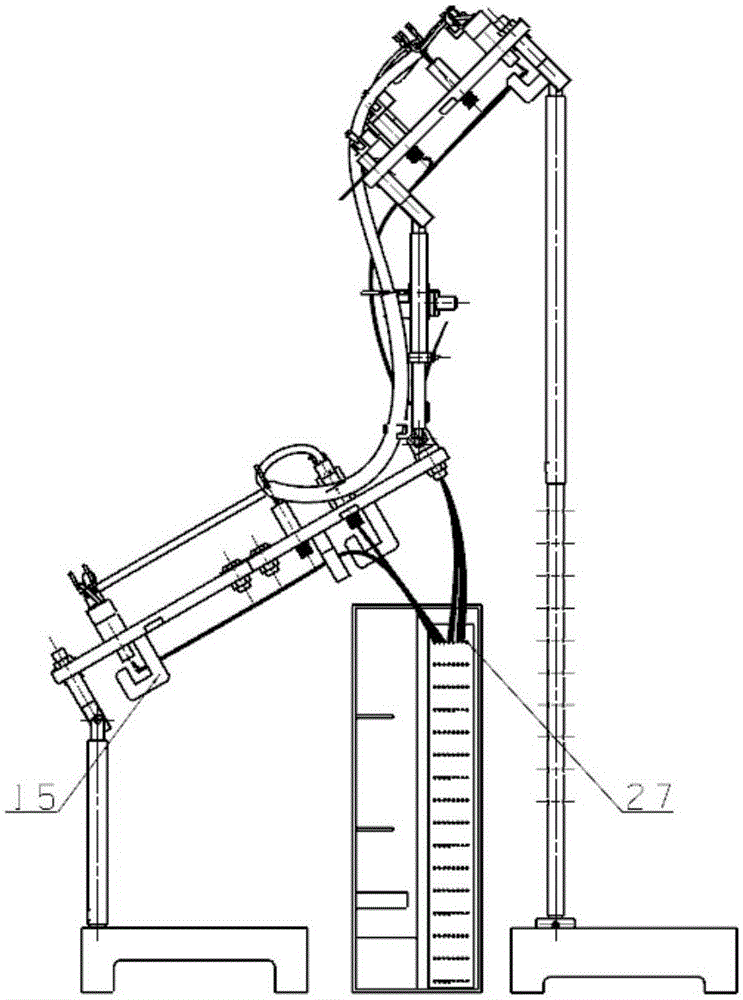

[0073] Such as Figure 4 shown.

[0074] A three-dimensional modularized wiring and detection integrated device for wire harness manufacturing, which mainly includes: two wiring board tooling for wire harness manufacturing, an angle adjustment mechanism, a positioning seat 11 for fixing wire harnesses and a binding belt 13, Based on the guided U-shaped fork element 14, the connector 6 for wire harness detection and the cabinet 2 for wire harness detection, the upper and lower wiring board fixtures have a vertical drop, and the upper and lower wiring board fixtures are multi-level wiring. The lower wiring board tooling is installed on the angle adjustment mechanism, the upper wiring board tooling is installed on the lower wiring board tooling through the rotatable telescopic rod 8, and the clamping of the two wiring board toolings is adjusted through the rotatable telescopic rod 8 Angular and vertical distances; such as Figure 4 shown. Each wiring board tooling is composed ...

example 3

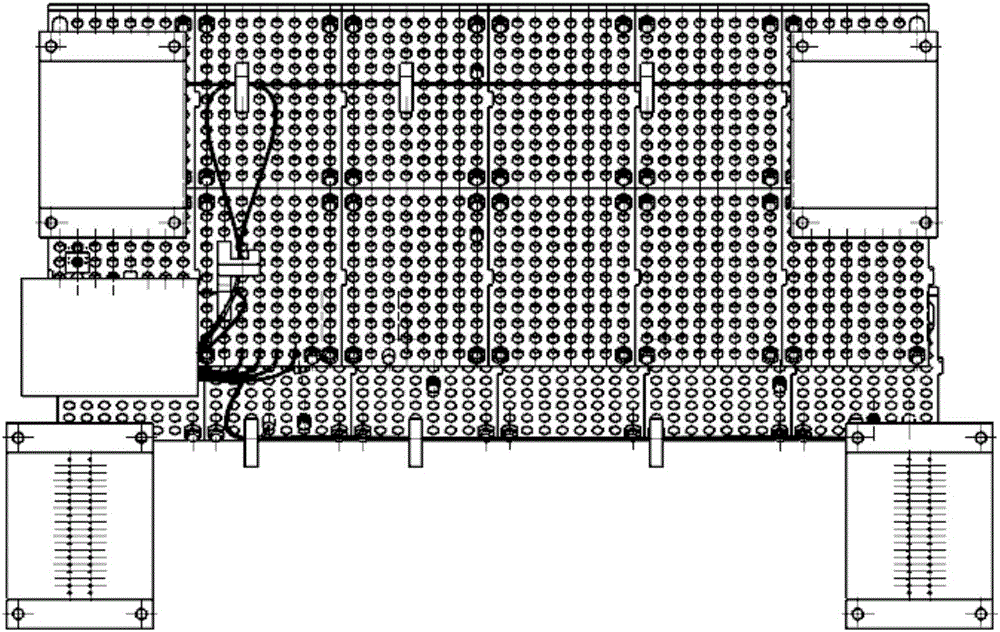

[0076] Such as Figure 5 shown.

[0077] A three-dimensional modularized wiring and detection integrated device for wire harness manufacturing, which mainly includes: two wiring board tooling for wire harness manufacturing, an angle adjustment mechanism, a positioning seat 11 for fixing wire harnesses and a binding belt 13, Based on the guided U-shaped fork element 14, the connector 6 for wire harness detection and the cabinet 2 for wire harness detection, according to the direction of the wire harness to be detected, the two wiring board toolings intersect in space, and the wiring board tooling at the bottom Directly installed on the angle adjustment mechanism, another intersecting wiring board tooling is connected with the wiring board tooling at the bottom through the surface hinge device 19, such as Figure 5 shown. Each wiring board tooling is composed of a plurality of porous wiring boards 1. The width direction of adjacent porous wiring boards 1 is connected with bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com