Preparation method of biomass tar industrial creosote

A production method and biomass technology, applied in the field of comprehensive utilization of agricultural waste, can solve problems such as agricultural ecological environment hazards, polluted soil and water sources, and achieve the effect of promoting development and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

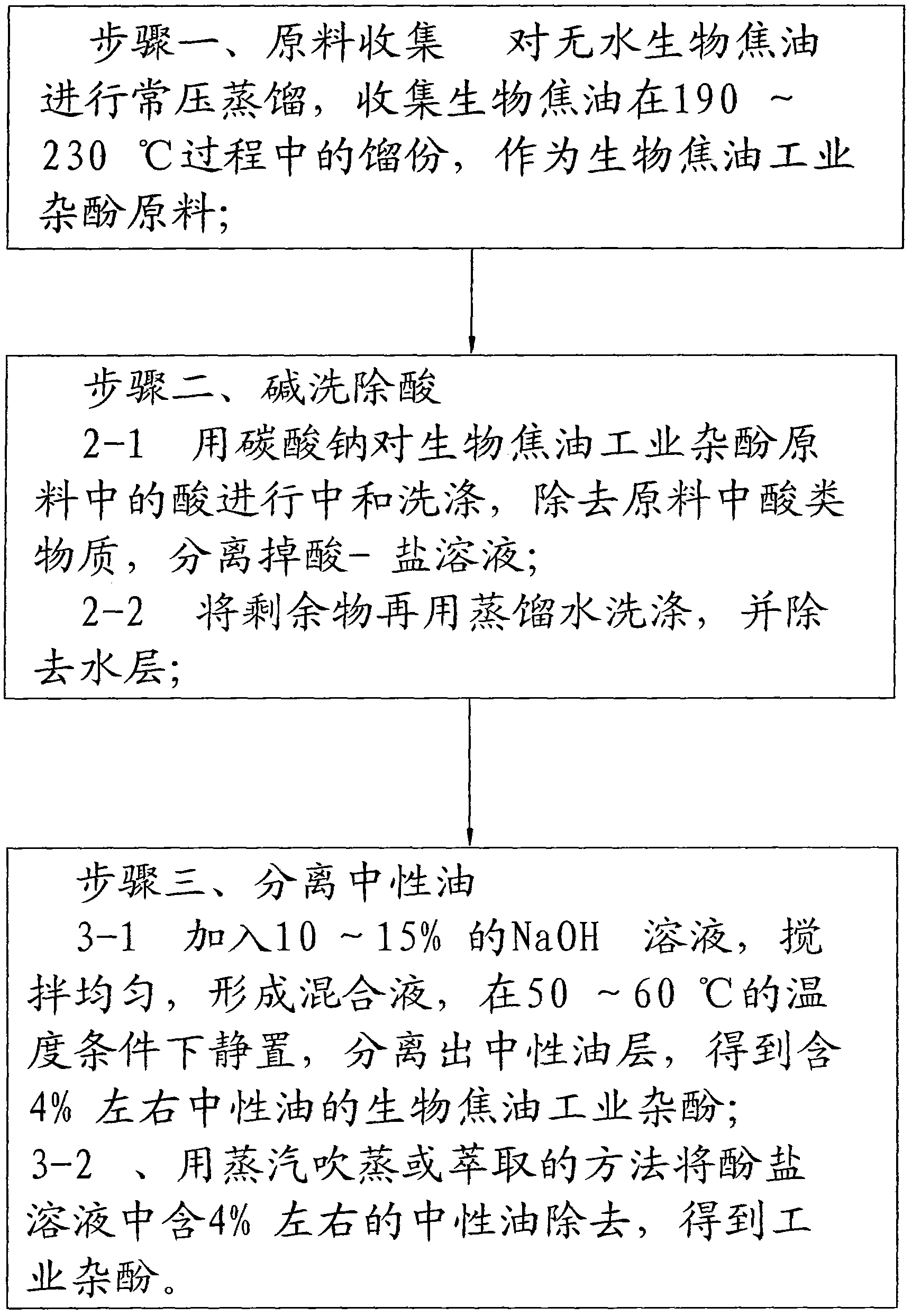

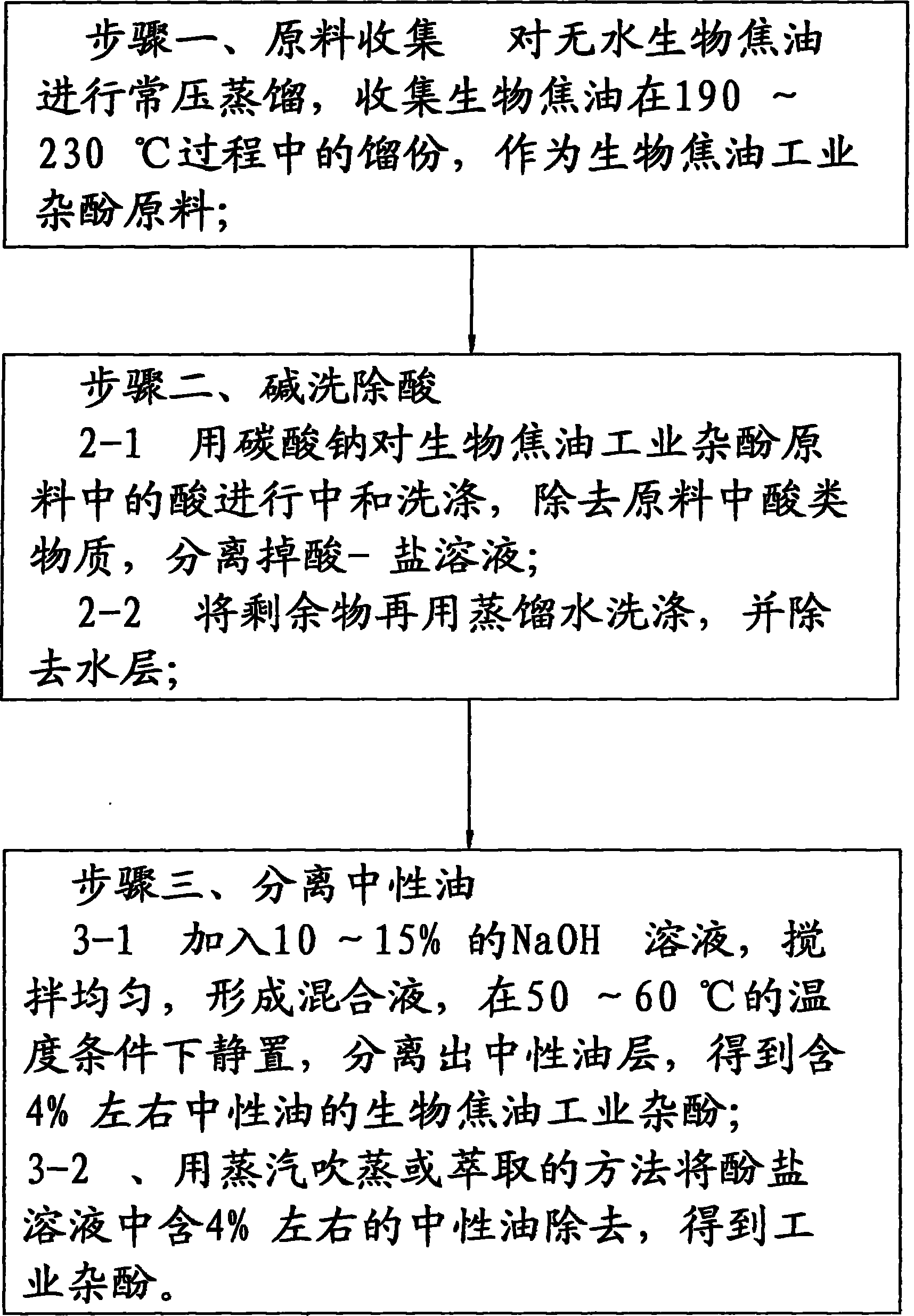

[0018] For further elaborating the technical means and effects that the present invention takes to reach the predetermined invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to its specific implementation, feature of the preparation method of biomass tar industrial creosote proposed according to the present invention And its effect, detailed description is as follows.

[0019] see figure 1 Shown, the preparation method of the biomass tar industrial creosote of preferred embodiment of the present invention is characterized in that comprising the following steps:

[0020] Step 1. Raw material collection Carry out atmospheric pressure distillation on the anhydrous biomass tar, collect the fraction of the biomass tar in the process of 190-230°C, and use it as the biomass tar industrial creosote raw material;

[0021] Step 2. Alkaline washing to remove acid

[0022] 2-1 Use sodium carbonate to neutralize and wash the acid in the biomass ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com