Method for preparing 4A zeolite molecular sieve with illite-containing kaolin

A technology of zeolite molecular sieve and kaolin, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of large difference in activation temperature, difficulty in preparing 4A molecular sieve, loss of activity, etc., and achieve product granularity The effect of uniform distribution, reduced influence, and relaxed operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The kaolin containing illite prepares the method for 4A zeolite molecular sieve, it may further comprise the steps:

[0029] (1) Using illite-containing kaolin as raw material, according to the mass ratio of kaolin and NaOH of 1:2, mix the two evenly, put them in a high-temperature furnace, calcined at 300°C for 2 hours, cool, grind and pulverize to obtain alkali-fired kaolin;

[0030] (2) Weigh 20g of alkali-burned kaolin, add it to 100ml of water, and stir vigorously in a water bath at 60°C for 2 hours to obtain a gelled product; then heat the gelled product to 90°C and stir at a low speed for 2 hours to obtain a crystallized product;

[0031] (3) Filter and dry the crystallized product to obtain 4A zeolite molecular sieve.

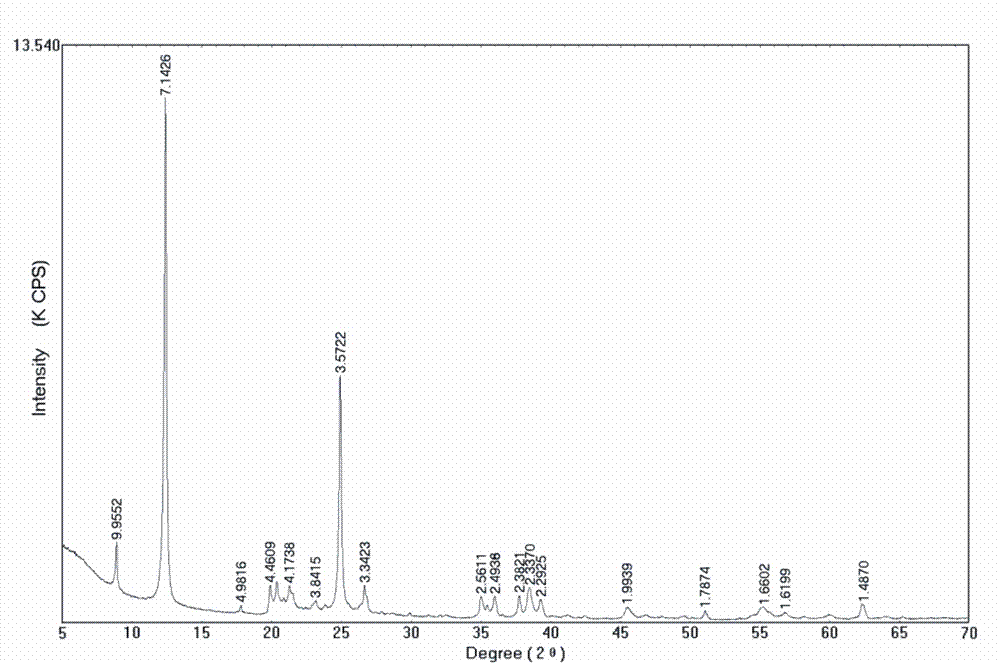

[0032] The calcium ion exchange capacity of the 4A molecular sieve prepared in this example is 311mgCaCO 3 / g - dry basis. Depend on figure 2 It can be seen that the synthetic product is a 4A zeolite molecular sieve with good crystallization ...

Embodiment 2

[0034] The kaolin containing illite prepares the method for 4A zeolite molecular sieve, it may further comprise the steps:

[0035] (1) Using illite-containing kaolin as raw material, according to the mass ratio of kaolin and NaOH of 1:2, mix the two evenly, put them in a high-temperature furnace, calcined at 400°C for 2 hours, cool, crush and grind to obtain alkali-fired kaolin;

[0036] (2) Weigh 20g of alkali-burned kaolin, add it to 100ml of water, and stir vigorously in a water bath at 60°C for 2 hours to obtain a gelled product; then heat the gelled product to 90°C and stir at a low speed for 2 hours to obtain a crystallized product;

[0037] (3) Filter and dry the crystallized product to obtain 4A zeolite molecular sieve.

[0038] The calcium ion exchange capacity of the 4A zeolite molecular sieve prepared in this example is 314mgCaCO 3 / g - dry basis.

Embodiment 3

[0040] The kaolin containing illite prepares the method for 4A zeolite molecular sieve, it comprises the following steps:

[0041] (1) Using illite-containing kaolin as raw material, according to the mass ratio of kaolin and NaOH of 1:2, mix the two evenly, put them in a high-temperature furnace, calcined at 300°C for 2 hours, cool, crush and grind to obtain alkali-fired kaolin;

[0042] (2) Weigh 20g of alkali-burned kaolin, add it to 100ml of water, and stir vigorously in a water bath at 50°C for 3 hours to obtain a gelled product; then raise the temperature of the gelled product to 70°C and stir at a low speed for 3 hours to obtain a crystallized product;

[0043] (3) Filter and dry the crystallized product to obtain 4A zeolite molecular sieve.

[0044] The calcium ion exchange capacity of the 4A zeolite molecular sieve prepared in this example is 299mgCaCO 3 / g - dry basis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com