Tri-anionic-nonionic surfactant and preparation method thereof

A non-ionic surface and active agent technology, applied in the direction of chemical instruments and methods, dissolution, drilling compositions, etc., can solve the problem that the length of the alkyl chain cannot be adjusted at will, the existence of ethylene oxide addition process, equipment and safety Require high-level problems, achieve the effect of low critical micelle concentration, excellent anti-decomposition ability, and high interfacial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of triple anion-nonionic surfactant mainly comprises following three continuous steps:

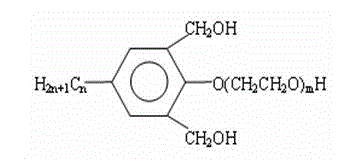

[0053] Step 1: Preparation of alkylphenol polyoxyethylene ether methylol intermediate: add 1 mol of alkylphenol polyoxyethylene ether with carbon number n and EO number m into the reaction vessel, add 0.2 to 1.2 mol of solid base or 50% liquid alkali, heat up to 40-60°C and stir evenly, add 2.0-3.0mol formaldehyde, keep the temperature at 50-80°C, react for 4-24 hours, and prepare the alkylphenol polyoxyethylene ether hydroxymethyl intermediate. The molecular structural formula is as follows:

[0054]

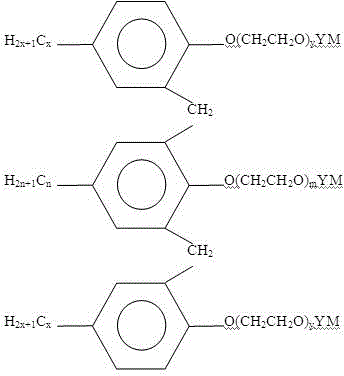

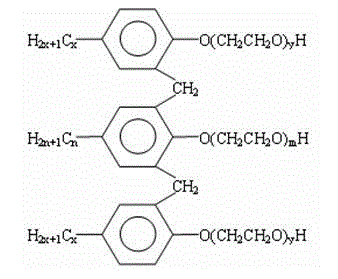

[0055] Step 2: Prepare triple alkylphenol polyoxyethylene ether nonionic surfactant: add 2 mol of alkylphenol polyoxyethylene ether with carbon number x and EO number y into the reaction vessel, adjust the pH to 6-7 with hydrochloric acid, Add an acidic catalyst, gradually raise the temperature to 60-80°C to remove moisture by vacuuming, then raise the temp...

Embodiment 1

[0071] Embodiment 1: Preparation of triple alkylphenol polyoxyethylene ether sodium acetate

[0072] Add 1 mol of octylphenol polyoxyethylene ether (4EO) to the reaction vessel, add 0.5 mol of solid sodium hydroxide, heat up to 55°C and stir evenly, add 2.2mol of formaldehyde solution, keep the temperature at 60°C, and react for 6 hours.

[0073]Add 2mol of nonylphenol polyoxyethylene ether (10EO) into the reaction vessel, adjust the pH to 6-7 with hydrochloric acid, add 5g of p-toluenesulfonic acid, gradually raise the temperature to 75°C and vacuumize to remove moisture, stir and react at 120°C for 4h .

[0074] Add 3 mol of solid sodium hydroxide and 500 ml of toluene to the reaction vessel, stir and raise the temperature to 110°C for reflux to separate the water, keep it at 110°C for 4 hours, cool down to 60°C, add 3.3 mol of sodium chloroacetate in batches, keep it warm for 4 hours, add hydrochloric acid to adjust When the pH is neutral, toluene and water are removed und...

Embodiment 2

[0075] Embodiment 2: Preparation of triple alkylphenol polyoxyethylene ether sodium ethyl sulfonate

[0076] Add 1mol of nonylphenol polyoxyethylene ether (10EO) into the reaction vessel, add 0.5mol of solid sodium hydroxide, heat up to 55°C and stir evenly, add 2.2mol of formaldehyde solution, keep the temperature at 60°C, and react for 6h.

[0077] Add 2mol of octylphenol polyoxyethylene ether (8EO) into the reaction vessel, adjust the pH to 6-7 with hydrochloric acid, add 5g of p-toluenesulfonic acid, gradually raise the temperature to 75°C and vacuumize to remove moisture, and stir the reaction at 120°C 4h.

[0078] Add 3 mol of solid sodium hydroxide and 500 ml of toluene to the reaction vessel, stir and raise the temperature to 110°C for reflux to separate the water, keep the temperature at 110°C for 4 hours, cool down to 60°C, add 3.3 mol of sodium chloroethylsulfonate in batches, and keep the temperature for 5 hours. Add hydrochloric acid to adjust the pH to neutral, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com