Triple anionic-nonionic surfactant, and preparation method and application thereof

A non-ionic surface, active agent technology, used in the preparation of sulfonates, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of reduced product yield, connection of one or two or three, etc. Alkali resistance, simplified preparation process and equipment, and the effect of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

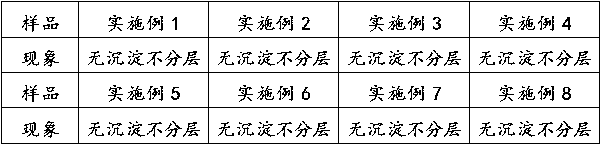

Examples

Embodiment 1

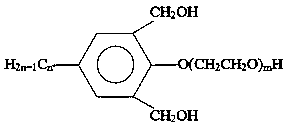

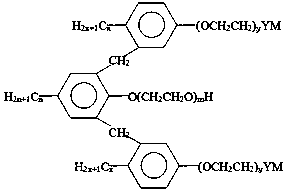

[0027] Example 1 Preparation of nonylphenol polyoxyethylene ether-3,5-dimethylene-didodecylphenol polyoxyethylene ether sodium sulfonate

[0028] Add 1mol of nonylphenol polyoxyethylene ether (10EO) into the reaction vessel, add 0.2mol of solid sodium hydroxide, heat up to 55°C and stir evenly, add 2.2mol of formaldehyde solution, keep the temperature at 60°C, and react for 6h.

[0029] Add 2 mol of dodecylphenol polyoxyethylene ether (10EO) sulfonic acid into the reactor, gradually raise the temperature to 90°C and stir for 10 hours to obtain the product. Use NaOH solution to adjust to neutrality, that is, sodium nonylphenol polyoxyethylene ether-3,5-dimethylene-didodecylphenol polyoxyethylene ether sulfonate.

[0030] .

Embodiment 2

[0031] Example 2 Preparation of potassium nonylphenol polyoxyethylene ether-3,5-dimethylene-didodecylphenylhydroxypropyl sulfonate

[0032] Add 1mol of nonylphenol polyoxyethylene ether (15EO) into the reaction vessel, add 0.5mol of solid sodium hydroxide, heat up to 55°C and stir evenly, add 3.0mol of formaldehyde solution, keep the temperature at 60°C, and react for 6h.

[0033] Add 2 mol of dodecylphenylhydroxypropyl sulfonic acid into the reactor, gradually raise the temperature to 100°C and stir for 8 hours to obtain the product. Use KOH solution to adjust to neutrality, that is, potassium nonylphenol polyoxyethylene ether-3,5-dimethylene-didodecylphenylhydroxypropyl sulfonate.

[0034] .

Embodiment 3

[0035] Example 3 Preparation of nonylphenol polyoxyethylene ether-3,5-dimethylene-didodecylphenol polyoxyethylene ether hydroxypropanesulfonate ammonium

[0036] Add 1mol of nonylphenol polyoxyethylene ether (30EO) into the reaction vessel, add 1.2mol of solid sodium hydroxide, heat up to 55°C and stir evenly, add 3.0mol of formaldehyde solution, keep the temperature at 60°C, and react for 24h.

[0037] Add 2 mol of dodecylphenol polyoxyethylene ether (5EO) hydroxypropanesulfonic acid into the reactor, gradually raise the temperature to 110°C and stir for 12 hours to obtain the product. use NH 4 The OH solution is adjusted to be neutral, that is, nonylphenol polyoxyethylene ether-3,5-dimethylene-dodedecylphenol polyoxyethylene ether hydroxypropanesulfonate ammonium.

[0038] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com