A kind of method utilizing kaolin to synthesize highly stable ordered mesoporous material al-sba-15

An al-sba-15, high-stability technology, applied in chemical instruments and methods, molecular sieve compounds, molecular sieves and alkali exchange compounds, etc., can solve the problems of kaolin and other problems, achieve lower synthesis costs, loose operating conditions, high water content The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

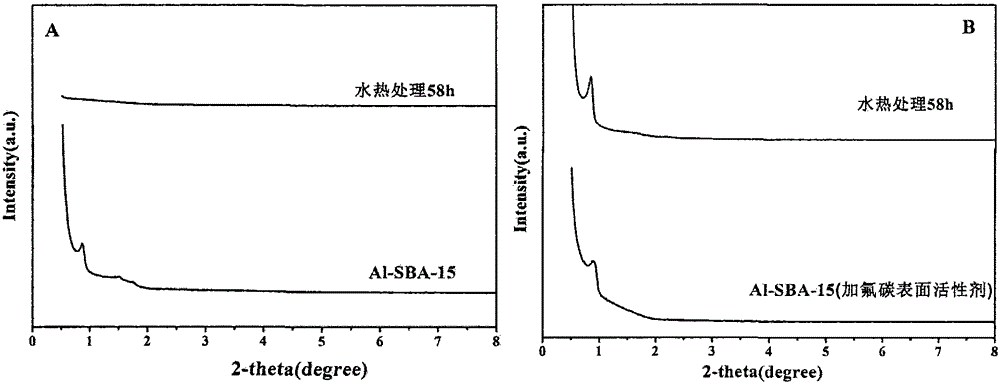

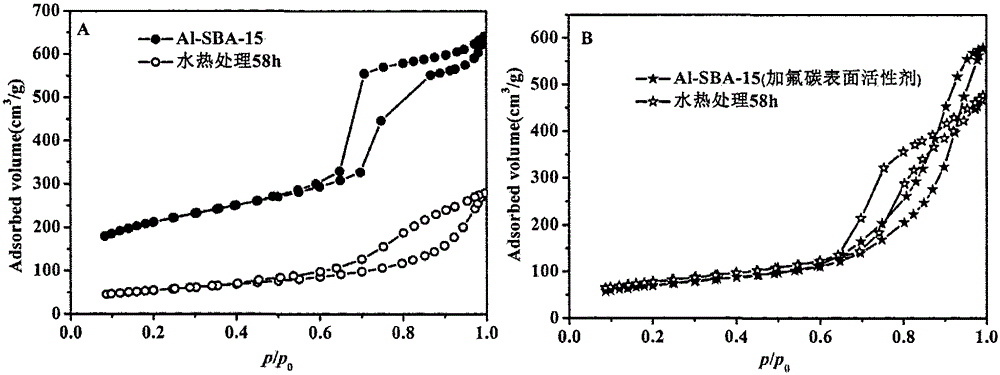

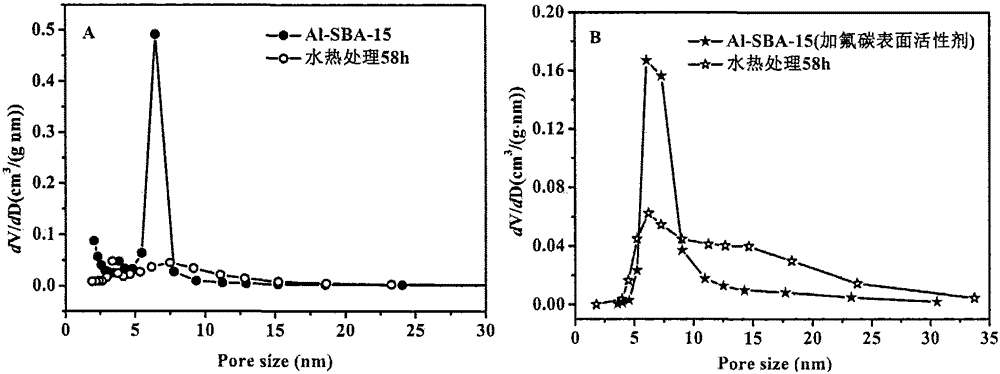

[0032] Activate the kaolin by roasting at 800°C for 3 hours, weigh 12g of the roasted kaolin, leaching with 6mol / L hydrochloric acid for 4h, then filter and wash with deionized water until neutral and dry; dry the dried sample at 950°C Roast for 2 hours; then put it into 5mol / L NaOH alkali solution, and react for 3 hours under high temperature and high pressure (temperature is 160°C and pressure is 0.5MPa). After the reaction is completed, adjust the pH value to 12.0 with hydrochloric acid. Then it was added dropwise to the acid solution of surfactant P123, stirred and reacted at 40°C for 24h, hydrothermally reacted at 100°C for 24h, filtered, washed and dried, then roasted at 550°C in a muffle furnace for 6h to obtain high stability Ordered mesoporous material Al-SBA-15.

Embodiment 2

[0034] Activate the kaolin by roasting at 800°C for 3 hours, weigh 12 g of the roasted kaolin, treat it with a mixed acid with a volume ratio of 4 mol / L sulfuric acid and hydrochloric acid of 0.4 for 4 hours, then filter and wash with deionized water until neutral and dry; The dried sample was roasted at 950°C for 2h; then put into 5mol / L NaOH alkali solution, and reacted at high temperature and high pressure for 3h (temperature was 160°C, pressure was 0.5MPa), after the reaction was completed, the pH value was adjusted with hydrochloric acid In 12.0. Then it was added dropwise to the acid solution in the mixed surfactant (n(FSO-100) / n(P123)=5.5, the concentration of hydrochloric acid was 7.5mol / L), stirred at 40°C for 24h, and hydrothermally heated at 160°C After reacting for 48 hours, filtering, washing and drying, it was calcined in a muffle furnace at 550°C for 6 hours to obtain Al-SBA-15, an ordered mesoporous material with high stability.

Embodiment 3

[0036]Activate the kaolin by roasting at 700°C for 4 hours, weigh 12g of the roasted kaolin, leaching with 6mol / L hydrochloric acid for 4h, then filter and wash with deionized water until neutral and dry; dry the dried sample at 950°C Roast for 2 hours; then put it into 5mol / L NaOH alkali solution, react for 3 hours under high temperature and high pressure (temperature is 160°C, pressure is 0.5MPa), after the reaction is completed, adjust its pH value to 14.0 with hydrochloric acid. Then it was added dropwise to the acid solution in the mixed surfactant (n(FSO-100) / n(P123)=5.5, the concentration of hydrochloric acid was 7.5mol / L), stirred at 40°C for 24h, and hydrothermally heated at 160°C After reacting for 48 hours, filtering, washing and drying, it was calcined in a muffle furnace at 550°C for 6 hours to obtain Al-SBA-15, an ordered mesoporous material with high stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com