Apparatus for Chopping and Discharging Straw from a Combine Harvester

a combine harvester and chopper technology, applied in the direction of tractors, mowers, agriculture tools and machines, etc., can solve the problems of spring seeding problems, inability to evenly distribute the chopper, and the traditional tailboard with fins not doing a good job distributing wet straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

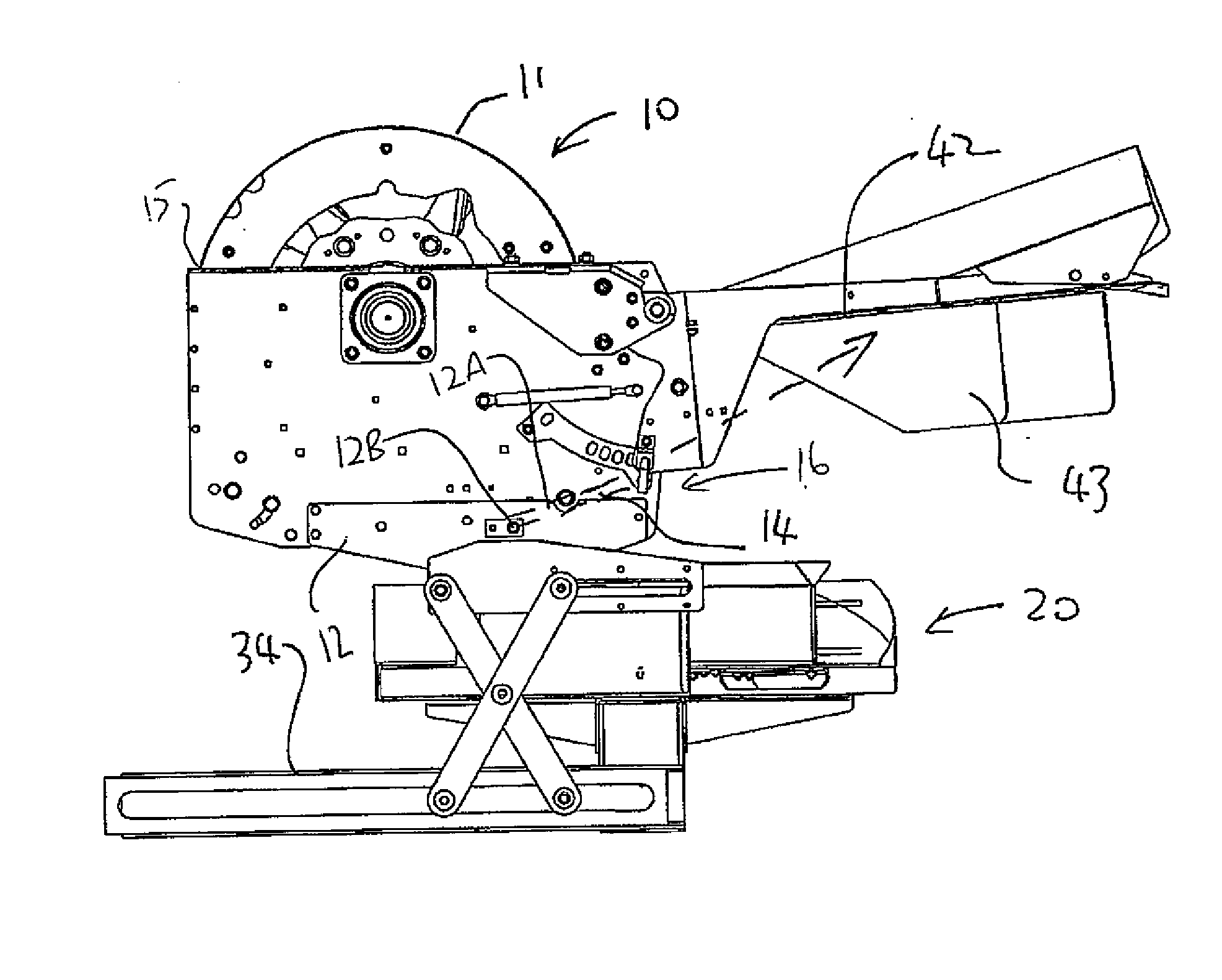

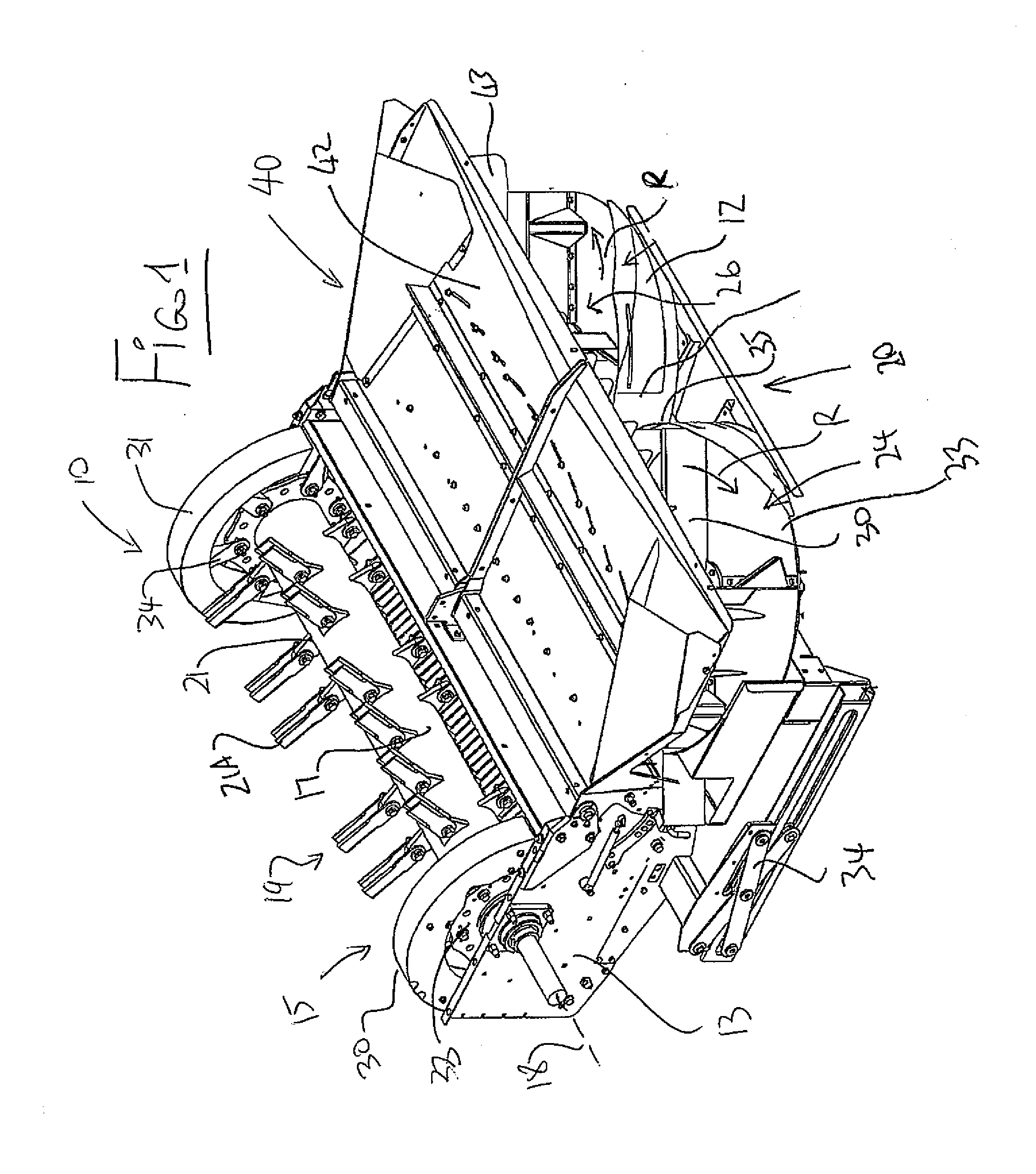

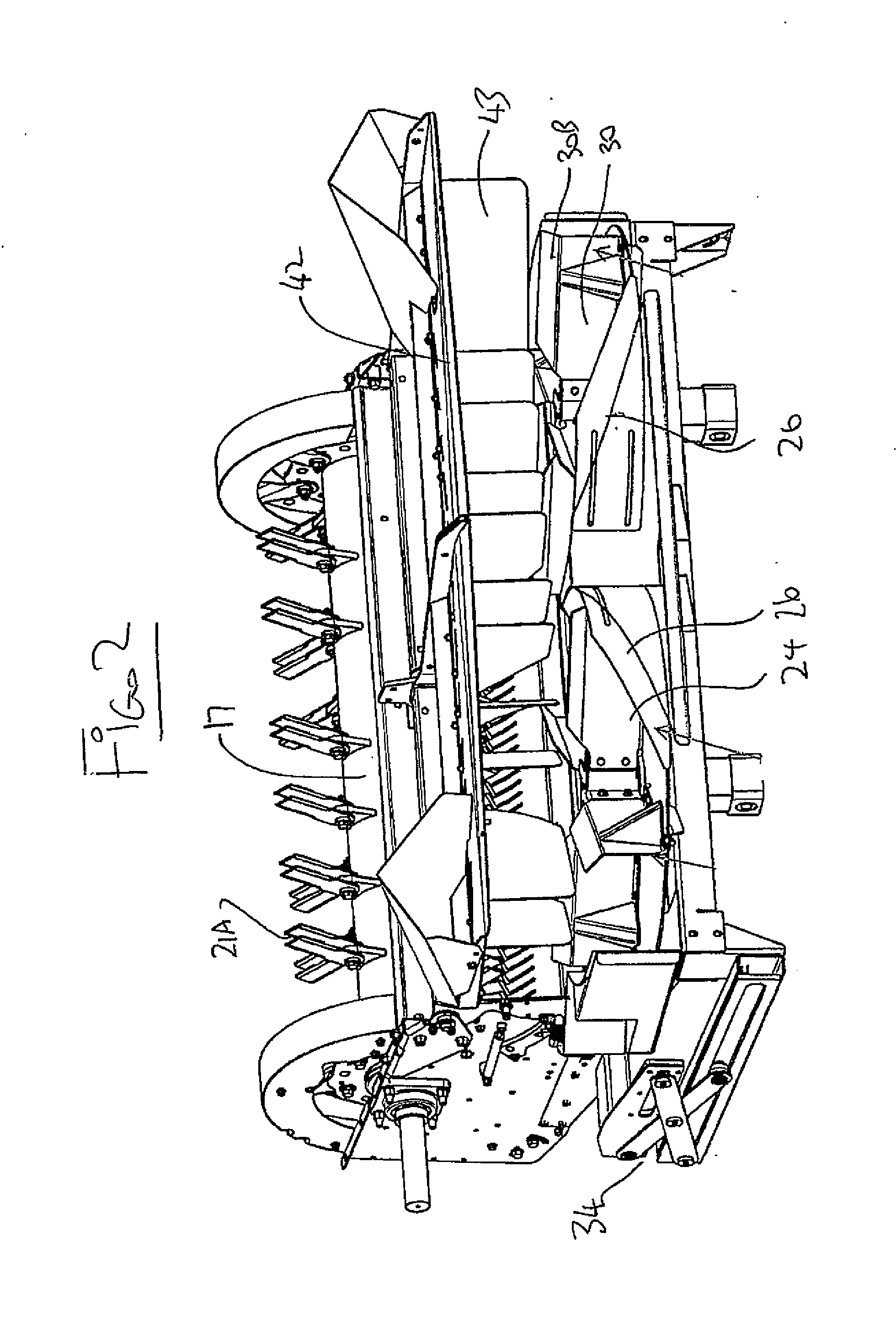

[0084]The chopper and discharge arrangement shown in FIGS. 1 to 4 is very similar to that from the prior patents of Redekop which are U.S. Pat. Nos. 5,232,405 and 5,482,508.

[0085]The apparatus which is basically as shown in U.S. Pat. No. 6,840,854 issued Jan. 11, 2005 of Redekop therefore comprises a housing 10 defined by a top wall 11, a bottom wall 12 and two end walls 13. The end walls 13 include attachment means for attachment of the housing to the outlet of a combine harvester for discharge of straw and possibly chaff from the combine harvester into an inlet opening 15 of the housing 10. The bottom wall 12 defines a semi-cylindrical portion extending from the inlet 15 to a discharge opening 16 through which chopped straw and air is discharged at relatively high velocity for spreading across the field or for transportation into a container.

[0086]Within the housing is mounted a hub 17 which is carried on suitable bearings for rotation about a hub axis 18 at a center of the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com