Cellulose and red alga polysaccharide plant empty capsule and raw material composition and preparation method thereof

A plant hollow capsule and raw material composition technology, applied in the direction of capsule transportation, can solve the problems of difficulty in realizing industrialization, affecting the disintegration time limit, easy to exceed the standard of microorganisms, etc., to ensure long-term stability, simple process, no cross-linking reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

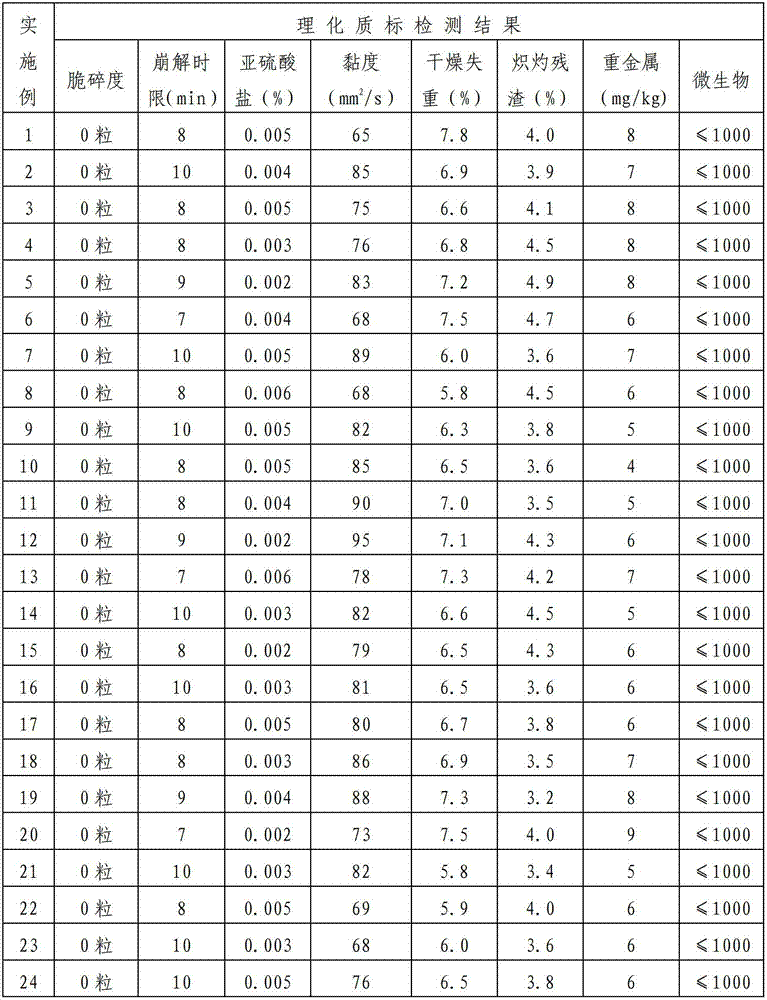

Examples

Embodiment 1

[0056] Ingredients weighing

[0057] Weigh 95 kg of raw material component A (hypromellose), 4 kg of red algal polysaccharide (3 kg of K-carrageenan, 1 kg of ι-carrageenan), and 1 kg of alcohols (glycerol) by weight; Mix component A and red algae polysaccharide with a two-dimensional mixer for 6 hours until uniform, and set aside;

[0058] Sol color matching

[0059] Add purified water 5 times the weight of raw materials into the sol tank, raise the temperature to 90°C, add the uniformly mixed materials in step , stir until completely dissolved, then add alcohol, cool down to 40°C to form a glue;

[0060] glue insulation

[0061] The glue formed in step was incubated at 45°C for 6 hours;

[0062] capsule making

[0063] The glue solution in step is dipped in glue, formed, dried, stripped, cut, and fitted on a fully automatic capsule production line to obtain the semi-finished capsule shell of the cellulose red algae polysaccharide plant hollow capsule; wherein, the v...

Embodiment 2

[0075] Raw material component A (hypromellose) 88 kg, red algae polysaccharide 11 kg (K-carrageenan 10 kg, ι-carrageenan 1 kg), alcohol (glycerol) 1 kg, other processes and equipment and Embodiment 1 is basically the same.

Embodiment 3

[0077] Raw material component A (hypromellose) 93.7 kg, red algae polysaccharide 5.3 kg (K-carrageenan 4.3 kg, ι-carrageenan 1 kg), alcohol (glycerol) 1 kg, other processes and equipment and Embodiment 1 is basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com