Pre-disintegration soft rock embankment grouting anti-seepage lifting structure and construction method thereof

A soft rock and embankment technology, applied in the field of pre-disintegrating soft rock embankment grouting anti-seepage lifting structure and its construction, can solve problems such as increased maintenance costs and engineering quantities, restrictions on the application of soft rock fillers, and affecting driver comfort , to achieve the effects of improving utilization rate, preventing uneven settlement, improving overall stability and local stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

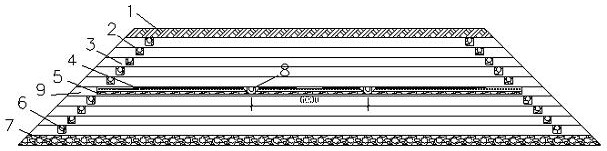

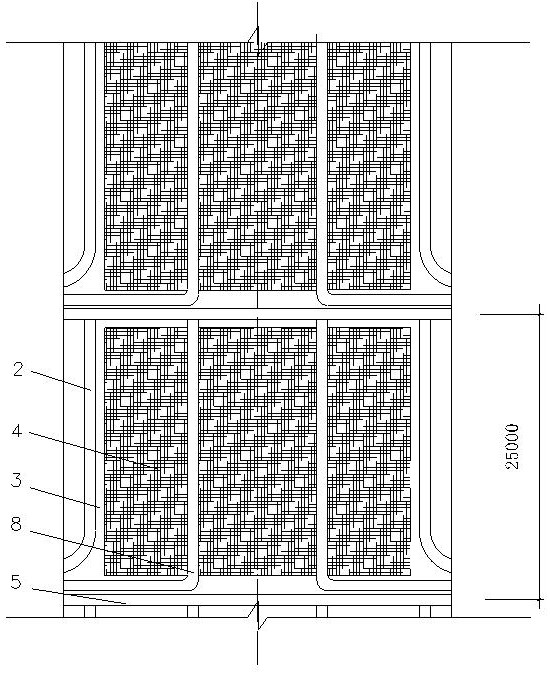

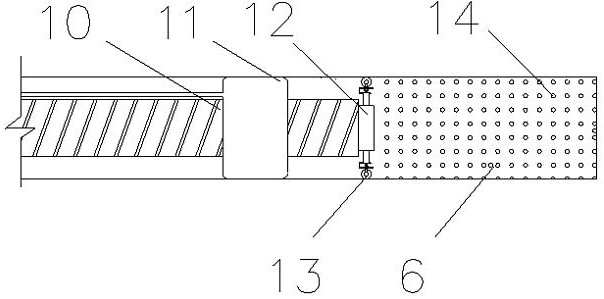

[0043] A pre-disintegrated soft rock embankment grouting anti-seepage lifting structure, such as Figure 1-2 shown, including:

[0044] The single-graded crushed stone layer 7 is laid on the bottom of the roadbed. The thickness of the single-graded crushed stone layer 7 is 50cm-100cm. It is used as a road bed to bear the upper load, and at the same time prevents the bottom groundwater from immersing into the soft rock filler layer 3, resulting in Wetting deformation causes uneven settlement of the road surface.

[0045]The soft rock filler layer 3 is laid layer by layer above the single graded crushed stone layer 7, the thickness of each layer of the soft rock filler layer 3 is 40~60cm, and each layer of soft rock filler layer 3 is excavated at a distance of 130~150cm from the edge of the embankment There is a first longitudinal reserved pouring pipe groove 2, and the first longitudinal reserved pouring pipe groove 2 is 30-50 cm wide and 30-50 cm high. An uplifted layer 9 is...

Embodiment 2

[0051] A construction method for grouting anti-seepage lifting structure of pre-disintegrating soft rock embankment, specifically carried out according to the following steps:

[0052] S1: laying a single graded crushed stone layer 7 at the bottom of the roadbed;

[0053] S2: Using the direct filling method, the soft rock filler is directly layered and compacted on the single-graded crushed stone layer 7 to form the soft rock filler layer 3, and the thickness of each layer of the rammed soft rock filler layer 3 is 50cm . The soft rock filler soil layer 3 serves as the main load-bearing structure of the subgrade, and bears the upper load and the vehicle load on the road surface. Considering the influence of rainfall and other climatic factors, the embankment side slope has a large wetting deformation problem, the thickness of the soft rock filler soil layer 3 can be appropriately reduced, and appropriate measures should be taken at the embankment side slope to repair the emban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com