Method of using gangue to prepare high purity molecular sieve ZSM-5

A ZSM-5, coal gangue technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of not yet high-purity molecular sieve, etc., to reduce the preparation cost and ease the operating conditions. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

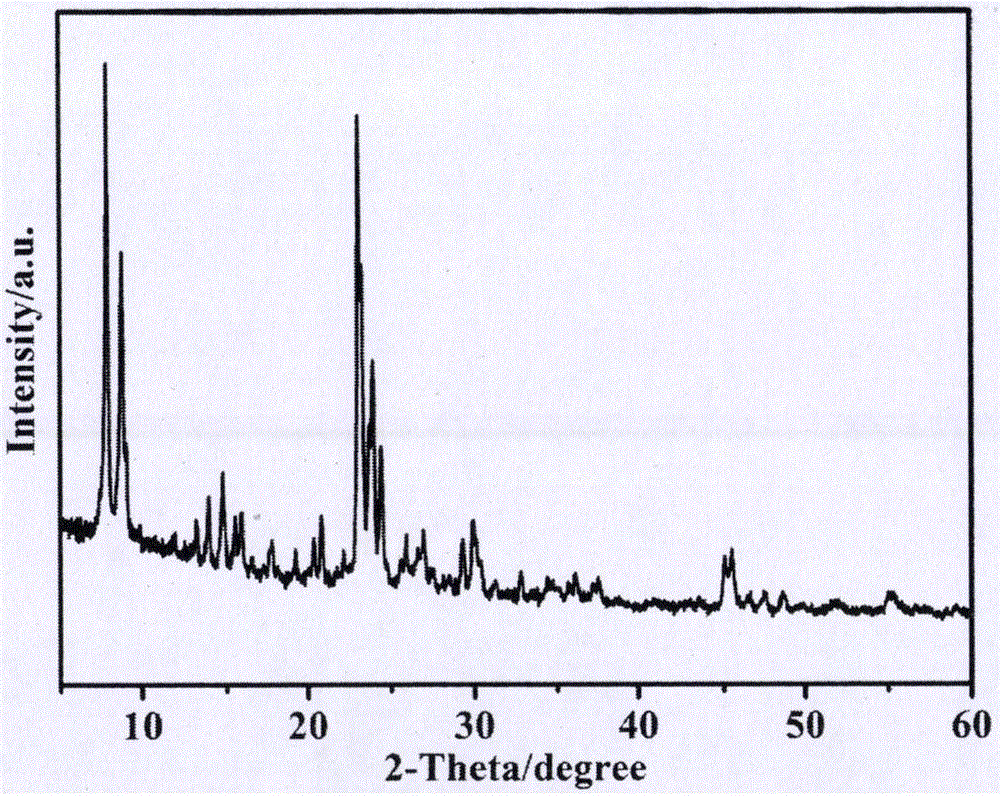

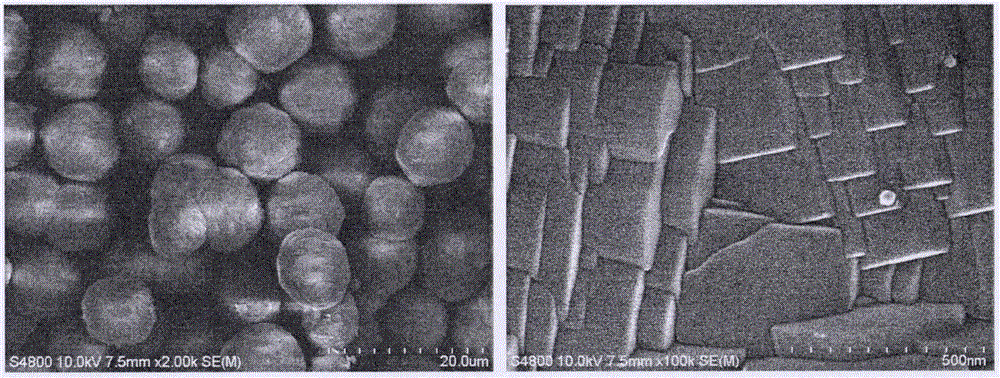

[0022] The coal gangue was roasted and activated at 850°C for 5 hours, and 25 g of the roasted coal gangue was weighed, treated with 6 mol / L hydrochloric acid for 4 hours, then filtered with deionized water, washed until neutral and dried; the dried samples were placed in Put into 5mol / I NaOH alkali solution, react under high temperature and high pressure for 3h (temperature is 160°C, pressure is 0.5MPa); after the reaction is completed, take 10mL of the reaction solution, adjust its pH value to 10.0 with hydrochloric acid; add 1.864g of tetrapropane Ammonium bromide (TPABr) and stirred for 12 hours, then transferred to a polytetrafluoroethylene reactor for hydrothermal reaction at 180°C for 24 hours, filtered, washed, dried, and roasted at 550°C for 4 hours in a muffle furnace to obtain high-purity molecular sieve ZSM -5.

Embodiment 2

[0024] The coal gangue was roasted and activated at 850°C for 5 hours, and 25 g of the roasted coal gangue was weighed, treated with 6 mol / L hydrochloric acid for 4 hours, then filtered with deionized water, washed until neutral and dried; the dried samples were placed in Add 8mol / L NaOH alkali solution, react under normal temperature and pressure for 3 days; After the reaction is completed, get the reaction solution 10mL, adjust its pH value at 10.0 with hydrochloric acid; add 1.864g of tetrapropylammonium bromide (TPABr) and stir After 12 hours, it was transferred to a polytetrafluoroethylene reactor for hydrothermal reaction at 180°C for 24 hours, filtered, washed, dried, and then roasted in a muffle furnace at 550°C for 4 hours to obtain high-purity molecular sieve ZSM-5.

Embodiment 3

[0026] The coal gangue was roasted and activated at 850°C for 5 hours, and 25 g of the roasted coal gangue was weighed, treated with 6 mol / L hydrochloric acid for 4 hours, then filtered with deionized water, washed until neutral and dried; the dried samples were placed in Put into 5mol / L NaOH alkali solution, react under high temperature and high pressure for 3h (temperature is 160°C, pressure is 0.5MPa); after the reaction is completed, take 10mL of the reaction solution, adjust its pH value to 10.0 with hydrochloric acid; add 1.864g of tetrapropane Ammonium bromide (TPABr) and stirred for 12 hours, then transferred to a polytetrafluoroethylene reactor for hydrothermal reaction at 140°C for 48 hours, filtered, washed, dried, and then roasted in a muffle furnace for 4 hours at 550°C to obtain high-purity molecular sieve ZSM -5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com