Catalyst for producing methylal by selective oxidation of methanol and preparation method and use thereof

A selective oxidation and methylal technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, preparation of organic compounds, etc., can solve the problem of low methanol conversion rate and methylal selectivity Low cost, no practical value, etc., to achieve the effect of simple preparation method, reduced production cost and investment cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

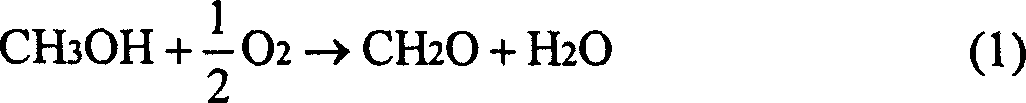

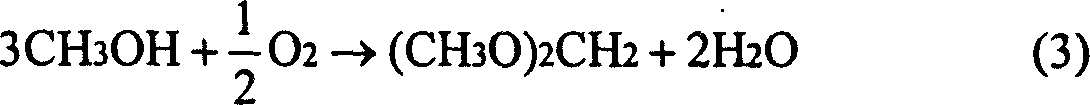

Problems solved by technology

Method used

Image

Examples

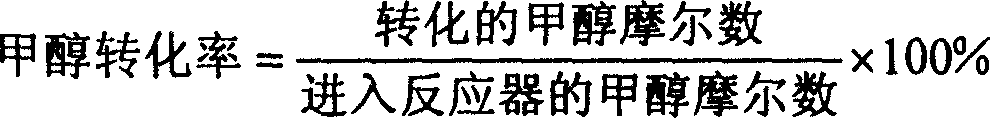

Embodiment 1

[0025] Mix 71.0g of ammonium metavanadate and 142.0g of oxalic acid, add 600.0ml of water, stir and dissolve to obtain a dark green solution, add 500.0g of powdered titanium dioxide to the above dark green solution and stir to form a light green paste, and place it for 2 hours Dry at 110°C for 12 hours, and then bake in air at 400°C for 6 hours to obtain 2 o 5 Yellow powdered vanadium-titanium catalyst A. A part of the prepared powdery vanadium-titanium catalyst A is pressed into a sheet, and then the sheet-shaped vanadium-titanium catalyst is smashed, sieved, and a particle size of 20-40 meshes is used for activity detection. Analyzing catalyst composition, V 2 o 5 Content 9.8%. This sample was designated as Catalyst #1 for comparison.

Embodiment 2

[0027] Mix 77.2g of ammonium metavanadate and 154.4g of oxalic acid, add 290.0ml of water, stir and dissolve to obtain a dark green solution, add 240.0g of powdered titanium dioxide to the above dark green solution and stir to form a light green paste, and leave it for 2 hours Dry at 110° C. for 12 hours, and then bake at 400° C. in air for 6 hours to obtain vanadium-titanium catalyst B in yellow powder form. A part of the prepared powdery vanadium-titanium catalyst B is pressed into a sheet, and then the sheet-shaped vanadium-titanium catalyst is smashed, sieved, and a particle size of 20-40 meshes is used for activity detection. Analyzing catalyst composition, V 2 o 5 Content 20.1%. This sample was designated #2 catalyst for comparison.

Embodiment 3

[0029] Put 6.2g of crystalline titanium sulfate into a 200ml crucible, add 150.0ml of distilled water and stir to dissolve it, weigh another 135.0g of titanium dioxide powder and add it to the above solution, stir for 10 minutes, let it stand for 5 hours and then dry it overnight at 110°C, then Calcined at 400°C for 5 hours to produce modified titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com