Method for degrading organic waste water by activating persulfate through manganese-cobalt composite oxide

A technology for activating persulfate and composite oxides, applied in the field of water treatment, can solve problems such as the application of organic wastewater that has not yet been invented, achieve high utilization rate, good removal effect, and reduce secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A typical method for preparing manganese oxides is:

[0029] (I) Take a certain amount of KMnO 4 and MnSO 4 (molar ratio 8: 3) was dissolved in water, and after stirring for one hour, the mixed solution was transferred to an autoclave, and heat treated at 160° C. for 12 hours;

[0030] (II) 2mmol of KMnO 4 Dissolve in deionized water, add concentrated sulfuric acid dropwise while stirring, put a 2cm×8cm copper plate, and heat in a water bath at 60°C for 8 hours;

[0031] (III) Take 4mmol of KMnO 4 Dissolved in deionized water and stirred, to KMnO4 A certain amount of glucose, ethylenediamine, and 1.4 mL of concentrated HCl solution were added to the solution, and the mixed solution was transferred to an autoclave for heat treatment at 120° C. for 12 hours.

[0032] Take samples I, II, and III respectively, filter them, wash them three times with deionized water, then wash them twice with absolute ethanol, dry them at 60°C for 24 hours, and calcinate the samples in a...

Embodiment 1

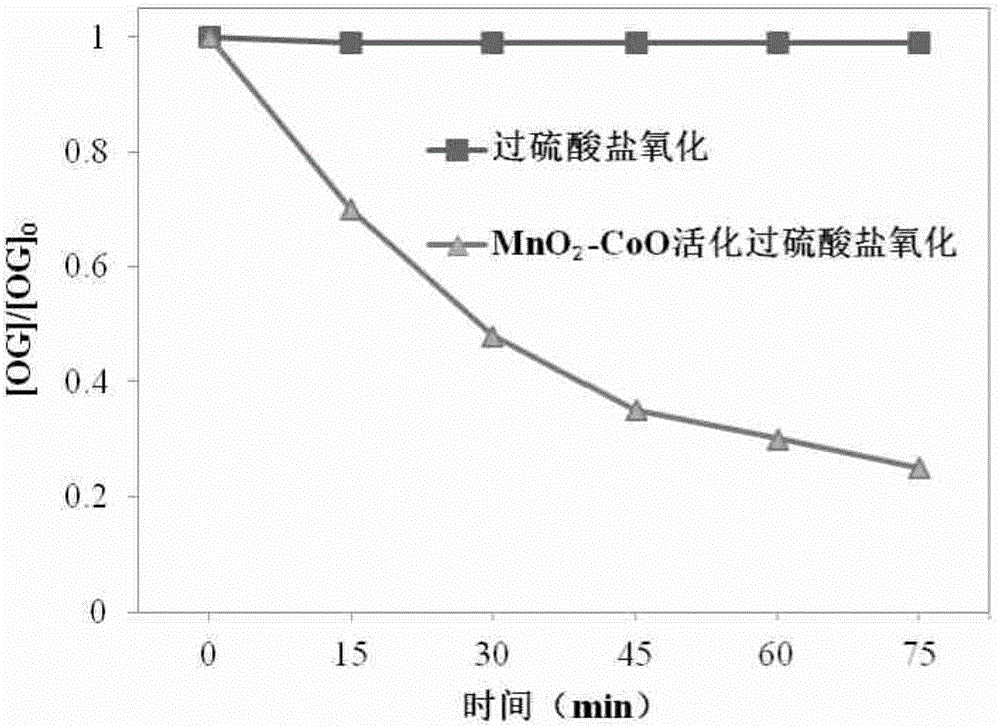

[0037] Example 1 Manganese-cobalt composite oxide activates persulfate to degrade printing and dyeing wastewater.

[0038] Take 500mL of the untreated water sample containing printing and dyeing wastewater, and the pH value is 7.0. Manganese-cobalt composite oxide (MnO 2 -CoO) 0.1g / L (of which, MnO 2 -CoO is prepared according to the steps of the hydrothermal method (I), and in the preparation of MnO 2 CoO particles were added during the process), persulfate 0.5mM, and the water sample was treated for 75min. Compared with the single persulfate oxidation method, the removal rate increased from 1% to 75%.

[0039] figure 1 It is the effect diagram of the removal of refractory organic matter in printing and dyeing wastewater in this example. The refractory organic matter is taken as orange G (OG). Indicates MnO 2 -CoO-activated persulfate oxidative degradation of organic wastewater removal rate curve.

Embodiment 2

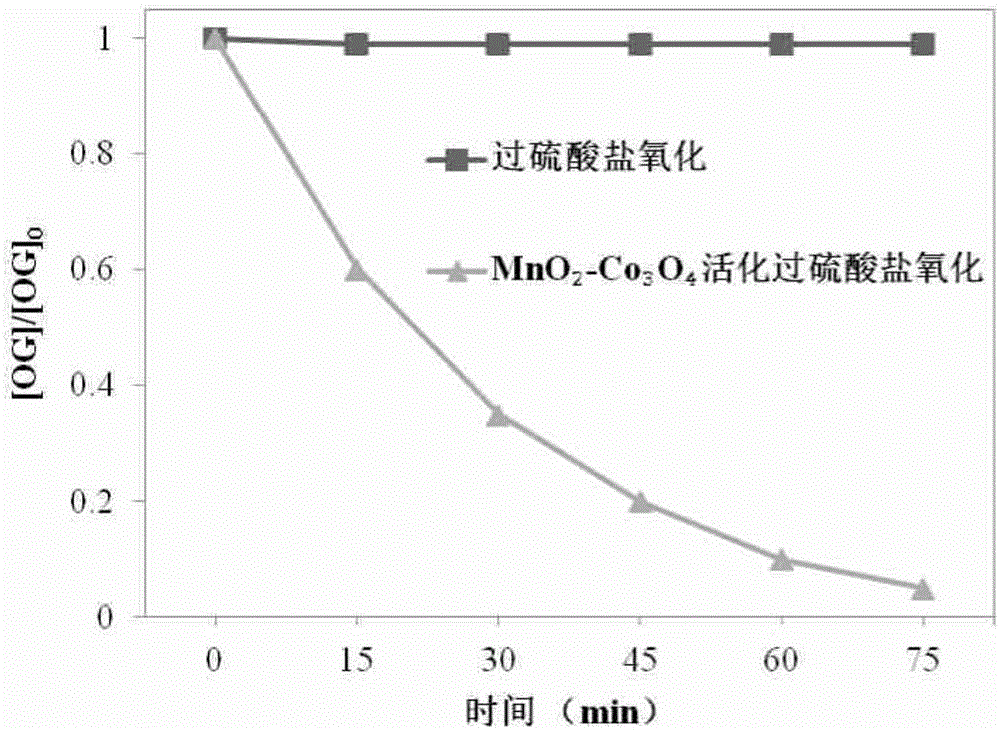

[0041] Take 500mL of the untreated water sample containing printing and dyeing wastewater, and the pH value is 7.0. Manganese-cobalt composite oxide (MnO 2 -Co 3 o 4 )2.0g / L (of which, MnO 2 -Co 3 o 4 The preparation is carried out according to the steps in the hydrothermal method (II), in the preparation of MnO 2 In the process of joining Co 3 o 4 Particles) persulfate 5mM, treatment of water samples for 75min, compared with single persulfate oxidation, the removal rate increased from 1% to 95%.

[0042] figure 2 It is the effect diagram of the removal of refractory organic matter in printing and dyeing wastewater in this example. The refractory organic matter is taken as orange G (OG). Indicates MnO 2 -Co 3 o 4 The removal rate curve of activated persulfate oxidative degradation of organic wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com