Method for removing thermostable salt in amine liquid for desulphurization

A technology for desulfurizing amine solution and thermally stable salt, which is applied in separation methods, chemical instruments and methods, ion exchange column/bed methods, etc., and can solve the problems of difficult treatment of desulfurizers, fast accumulation of sulfate radicals, and large total amount. , to achieve the effect of balancing regeneration difficulties, balancing the exchange rate is slow, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

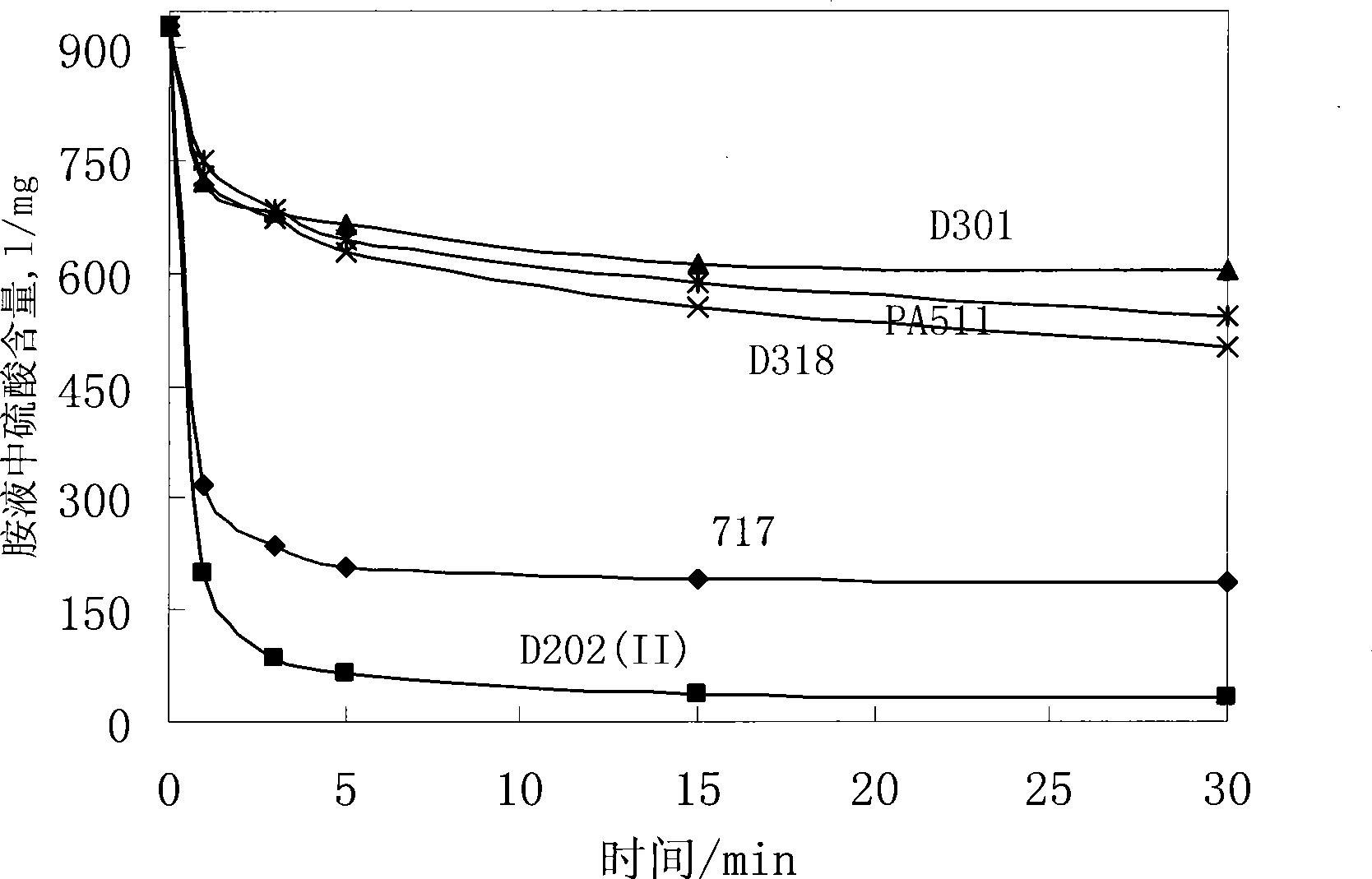

[0027] Add 25ml of fresh 717 (201×7) strong basic anion exchange resin that has been pretreated and transformed into OH type into five 200ml beakers respectively, and add 75ml of amine solution with a sulfate content of 12000mg / L for ion exchange test . The first beaker stops stirring after 1 minute, separates the resin and the amine solution, washes the resin 3 times with deionized water, collects the mixed amine solution and constant volume, analyzes the sulfate ion content, and calculates the total amount of sulfate radical remaining in the solution; then After 3 minutes, after 5 minutes, after 15 minutes, and after 30 minutes, the exchange test was performed sequentially. According to the content change of sulfate ion in the amine liquid, evaluate the exchange rate of sulfate ion on the resin.

[0028]According to the above method, measure the exchange rate of 202II type strongly basic anion exchange resin, D301 weakly basic anion exchange resin, D318 weakly basic anion e...

Embodiment 6~10

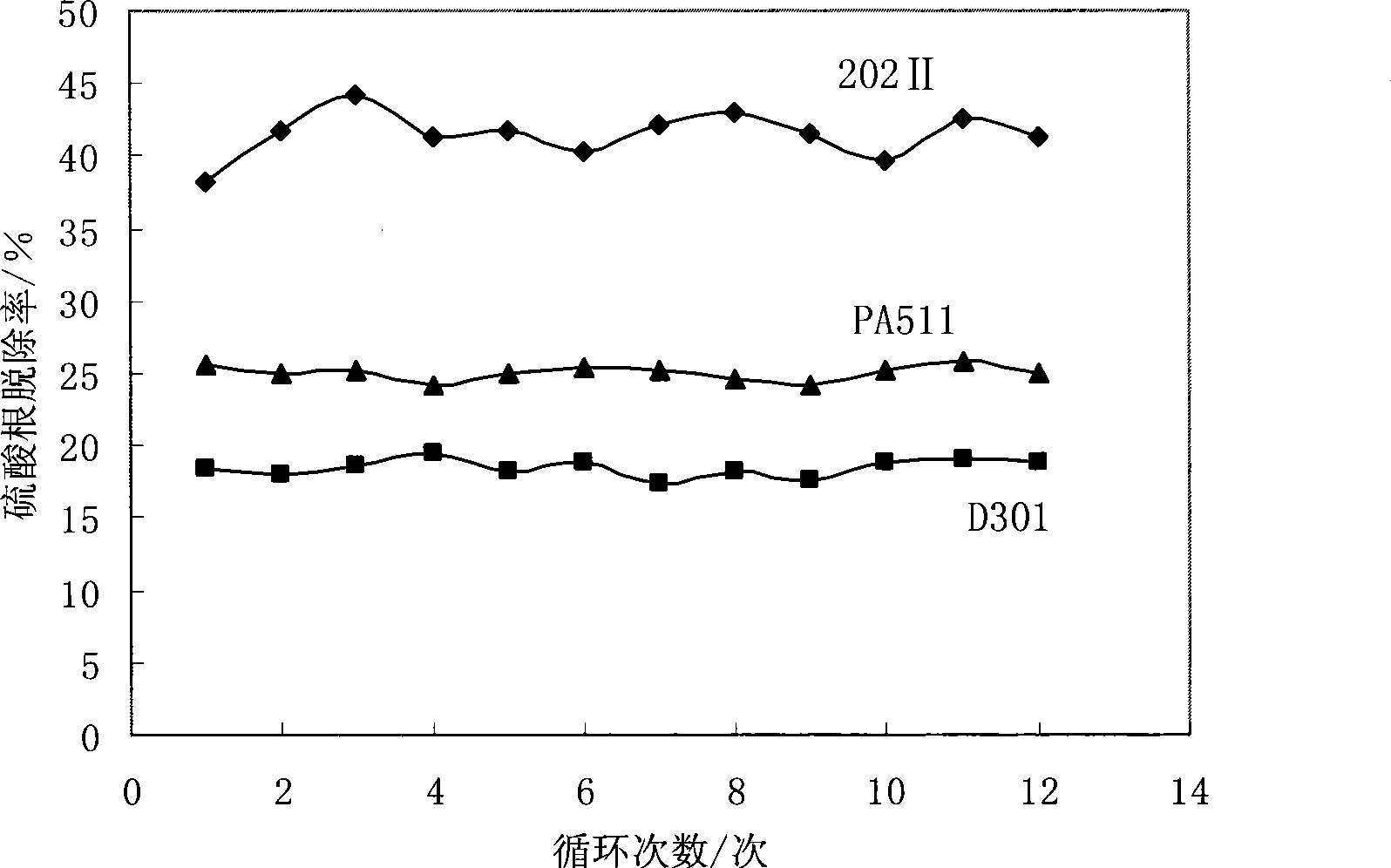

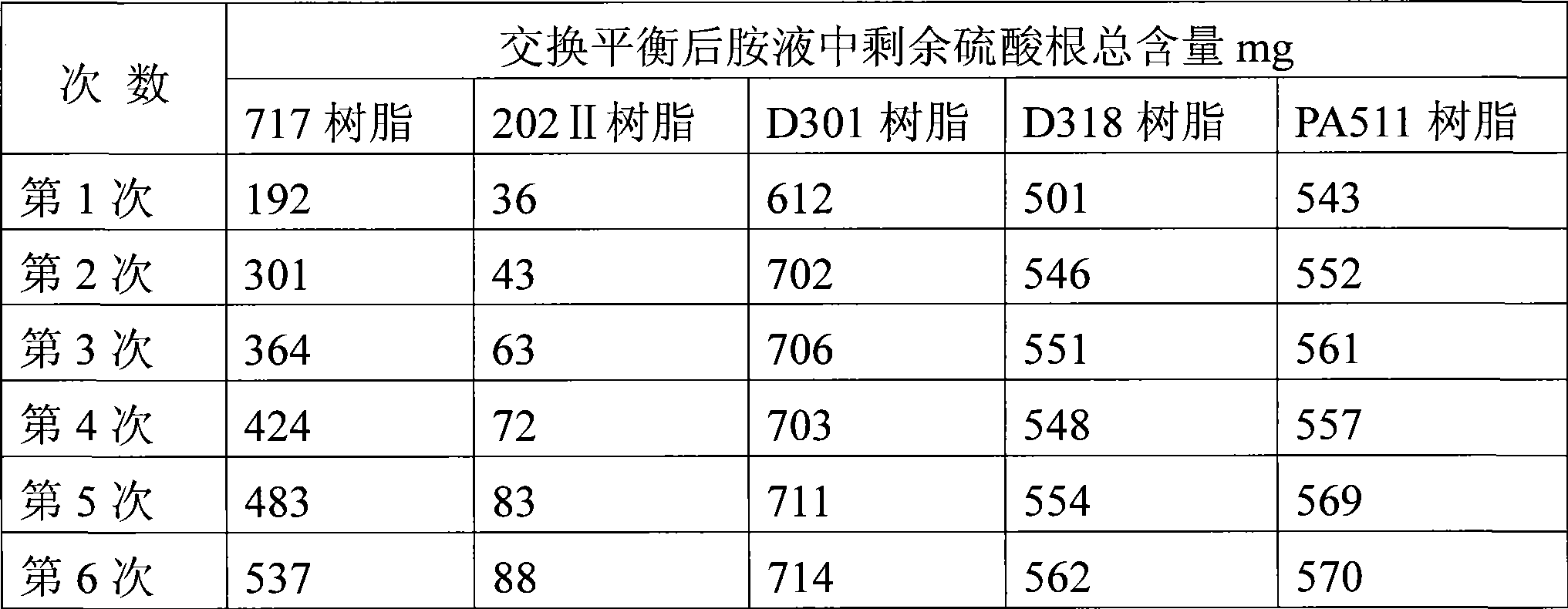

[0032] In the 200ml beaker, pack 25ml pre-treated 717 type strongly basic anion exchange resin, then add 75ml of amine solution with sulfate radical content of 12000mg / L, start stirring, carry out ion exchange test, control exchange time is 15 minutes, then Separate the resin and the amine solution, wash the separated resin three times with deionized water, collect the mixed amine solution and constant volume, analyze the sulfate content, and calculate the remaining total amount of sulfate in the amine solution. After the resin is rinsed, soak it with 75ml of 4% sodium hydroxide solution for 15 minutes, and then rinse it with deionized water until neutral. Repeat the above exchange test 6 times after regeneration to investigate the regeneration performance of the resin.

[0033] According to the above method, the regeneration performance of 202II strong base anion exchange resin, D301 weak base anion exchange resin, D318 weak base anion exchange resin and PA511 weak base anion...

Embodiment 11~13

[0038] Put 500ml D301 type weakly basic anion exchange resin in a plexiglass exchange column with a diameter of 70mm and a height of 210mm, and pump 1.5L of desulfurizer with a sulfate radical content of 70000mg / L within 5 minutes for ion exchange test, and collect and purify the mixed solution , analyze the sulfate content, and calculate the sulfate removal rate. The rinsed resin column is regenerated by pumping 1.5L of 4% sodium hydroxide solution countercurrently, and the alkali injection time is 10 minutes, and then rinsed with deionized water to neutrality, and enters the next purification cycle after the regeneration of the resin is completed.

[0039] According to the above method, the heat stable salt removal rate and stability of PA511 and 202II resins in the purification of desulfurizers were investigated in turn. The result is as figure 2 shown.

[0040] Depend on figure 2 It can be seen that the use of weak base resin D301 and strong base II resin can obtain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com