Preparation for modified MIL-53(Fe) metal organic framework and method for treating organic wastewater with activated persulfate thereof

A metal-organic framework and organic wastewater technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of easy deactivation of catalysts, insufficient active center sites, and reaction cycle Long and other problems, to achieve the effect of strong catalyst recyclability, easy operation, and improved degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of modified MIL-53(Fe) metal-organic framework and its catalytic activation of persulfate to treat golden orange G simulated wastewater, the specific operation steps are as follows:

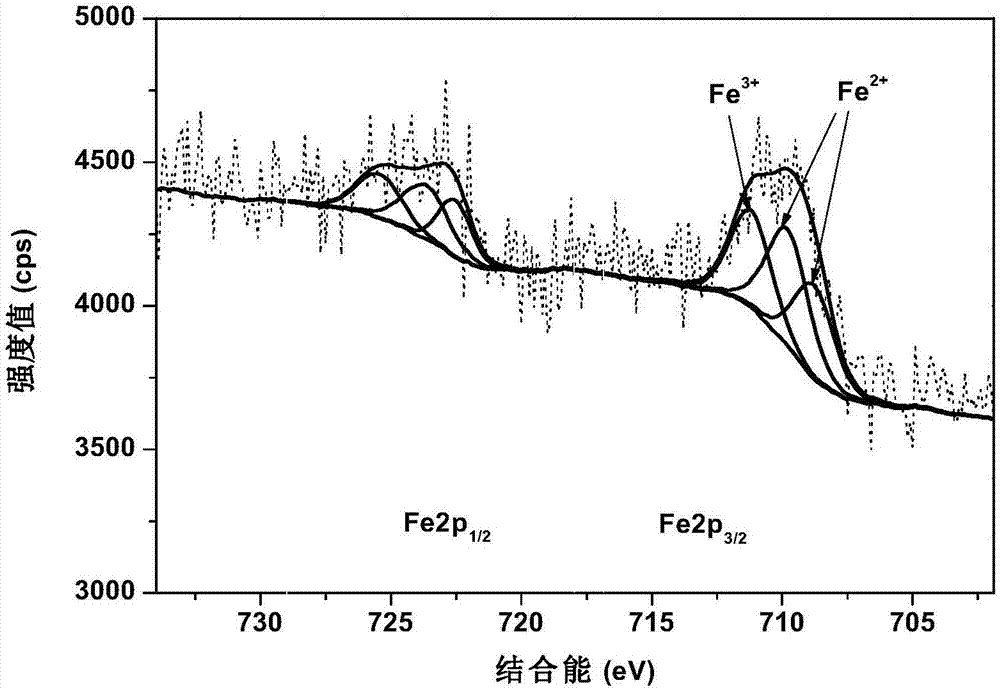

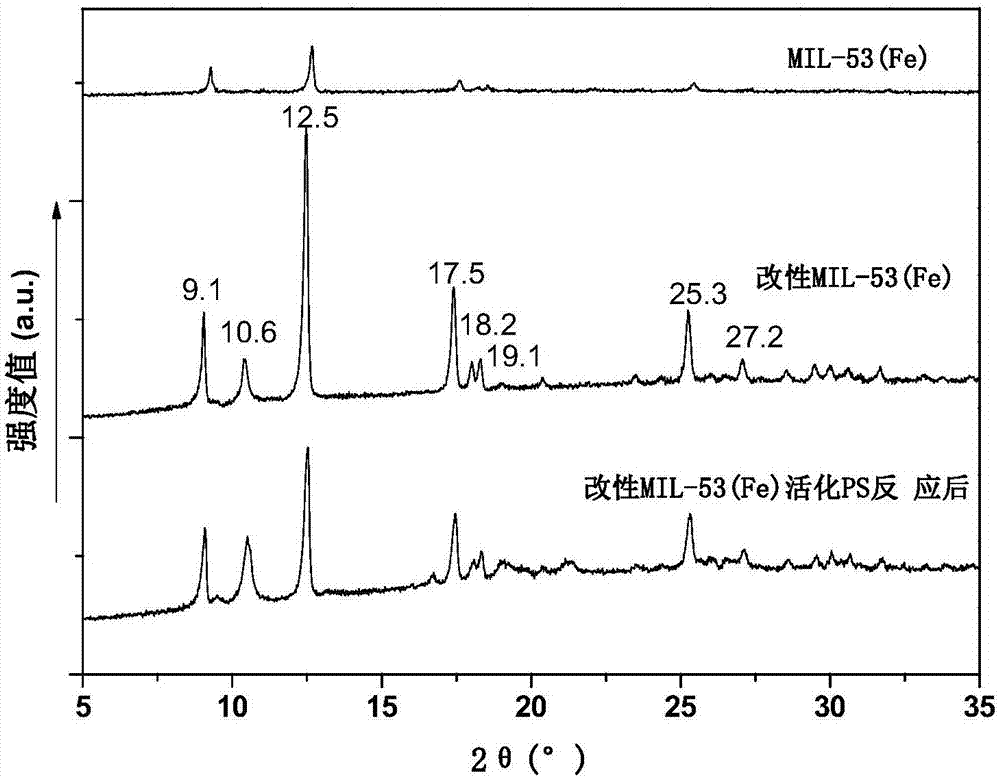

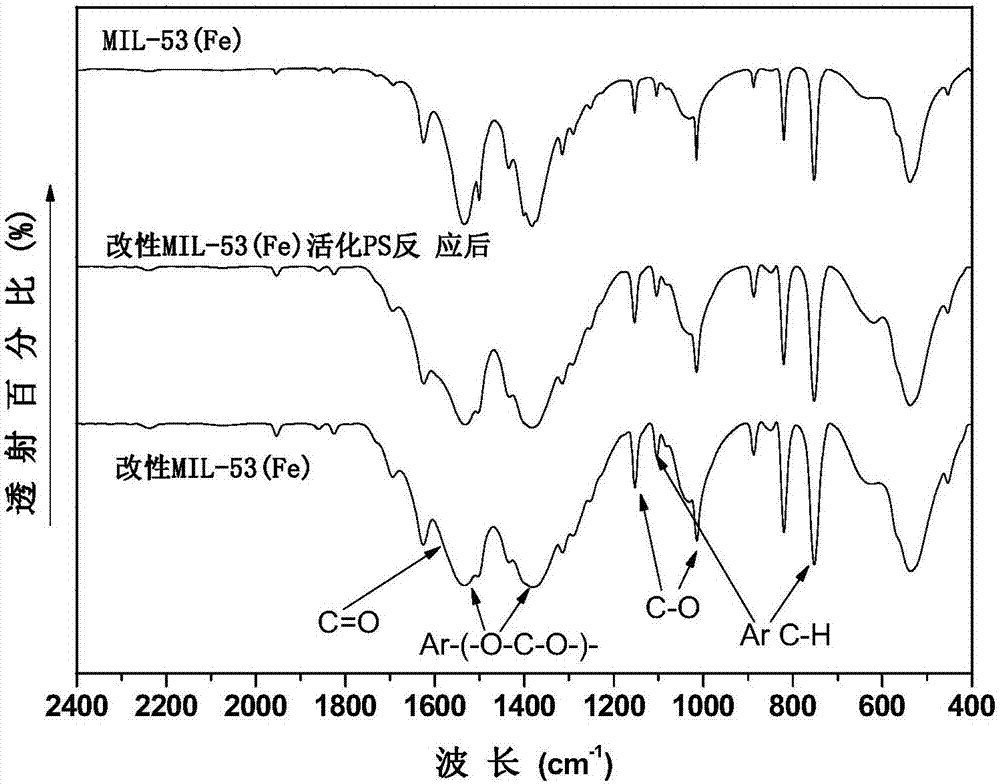

[0037] (1) Preparation Method 1 of Modified MIL-53(Fe) Metal Organic Framework: Weigh 0.995g (5mmol) FeCl 2 4H 2 O and 0.831g (5mmol) 1,4-BDC were poured into 25mL DMF and stirred for 20min to mix well. Pour the mixed solution into a 100mL polytetrafluoroethylene-lined reaction kettle, and place it in an electric thermostat blast drying oven preheated to 150°C. After 5 hours, the reactor was taken out and cooled to room temperature naturally. Separate the solid from the liquid by filtration or centrifugation, and wash the solid with methanol and then deionized water. Finally, the above solid was dried in an oven at 65° C. to obtain the modified MIL-53(Fe) metal-organic framework.

[0038] (2) Preparation method 2 of modified MIL-53(Fe) metal-organic framework: the diffe...

Embodiment 2

[0049] The material prepared under the conditions of the preparation method 1 of the modified MIL-53(Fe) metal organic framework in Example 1 is used as a catalyst, and sodium persulfate is used as an oxidant to simulate the initial COD of Jincheng G wastewater Cr 120mg / L, set four treatment groups, respectively: (1) add 1.0g / L modified MIL-53 (Fe) metal organic framework - 7.6g / L sodium persulfate - Jincheng G wastewater; (2) Add 1.0g / L modified MIL-53(Fe) metal organic framework—Golden Orange G wastewater; (3) Add 7.6g / L sodium persulfate—Golden Orange G wastewater; (4) Add 1.0g / L unmodified MIL-53(Fe)—7.6g / L Sodium Persulfate—Golden Orange G Wastewater. Take four 250mL Erlenmeyer flasks as reaction flasks, add the solutions set by the above three treatment groups to the reaction flasks respectively, and fully stir the reaction at 25°C, and take samples at 20min, 40min, 60min, 90min and 120min respectively Determination of wastewater COD Cr , the results are shown in Table...

Embodiment 3

[0054] Use a 250mL Erlenmeyer flask as a reaction flask to prepare COD Cr The golden orange G (OG) dye waste water that is 120mg / L, with the preparation method 1 of modified MIL-53 (Fe) metal-organic framework among the embodiment 1 as the material that the condition prepares is catalyst, and sodium persulfate is oxidizing agent, does not adjust Wastewater pH, set up five treatment groups: after adding 7.6g / L sodium persulfate, add catalyst 0.1g / L (treatment group 1), 0.3g / L (treatment group 2), 0.5g catalyst respectively to five groups of reaction flasks / L (Treatment Group 3), 1.0g / L (Treatment Group 4), 1.5g / L (Treatment Group 5), fully stirred at 25°C for reaction, and samples were taken at 20min, 40min, 60min, 90min and 150min respectively And measure the wastewater COD Cr , the results are shown in Table 3.

[0055] table 3

[0056]

[0057]

[0058] The results in Table 3 show that the amount of modified MIL-53 (Fe) metal-organic framework has a certain effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com