Production of phosphoric acid by a two-stage crystallization process

A phosphoric acid, phosphate technology, applied in the direction of phosphoric acid, phosphorus oxyacid, phosphorus compound, etc., can solve problems such as increased production cost, high denaturation, poor filtration or filtration variability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

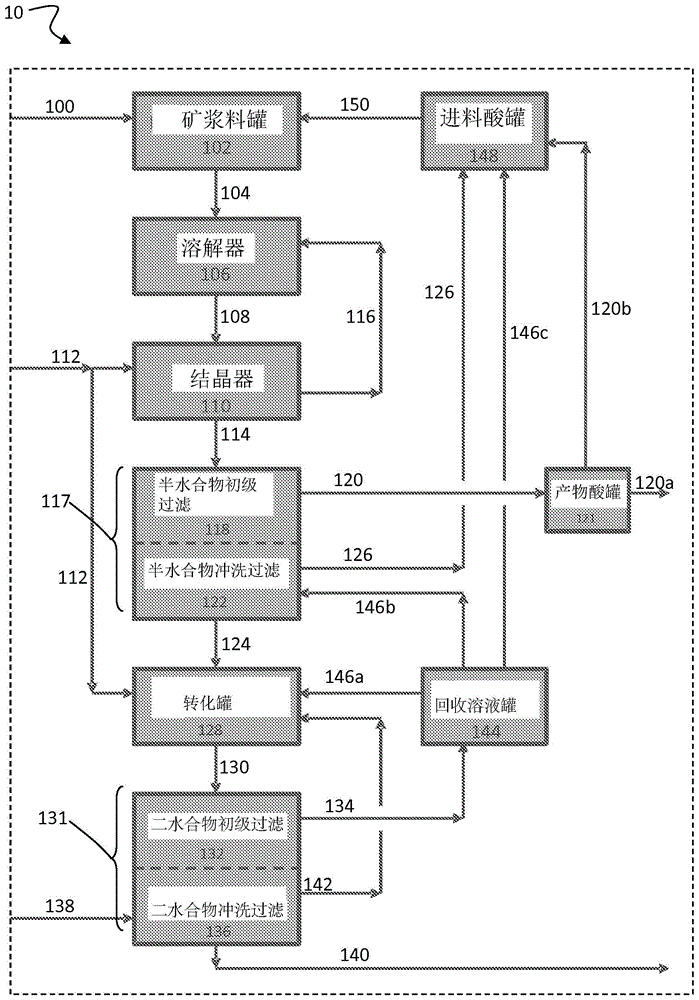

[0033] In an embodiment of the present invention, a hemihydrate / dihydrate process 10 for the production of phosphoric acid (hereinafter referred to as "HH-DH process 10") includes two stages of crystallization and filtration to achieve P 2 o 5 High recovery and high strength (or high concentration) product acid. Additionally, the process 10 includes a feed acid tank assembly 148, which includes one or more tanks in which product acid and other recycle streams are mixed before being introduced into the initial reactor or slurry tank as a single feed acid stream , measuring, and optionally adjusting, allowing better process controllability and process efficiency while reducing process variability and sampling error. The process 10 also includes a recovery solution tank assembly 144, which includes one or more tanks in which the recovery solution from the dihydrate filtration step 132 is directed back to the process 10 at various points as one or more recycle streams. Before it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com