Method for treating magnesium sulfate wastewater by lime-base process

A technology of magnesium sulfate and lime method, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of complex process, environmental pollution, high operation requirements, etc., and achieve simple equipment and low operating cost Low, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

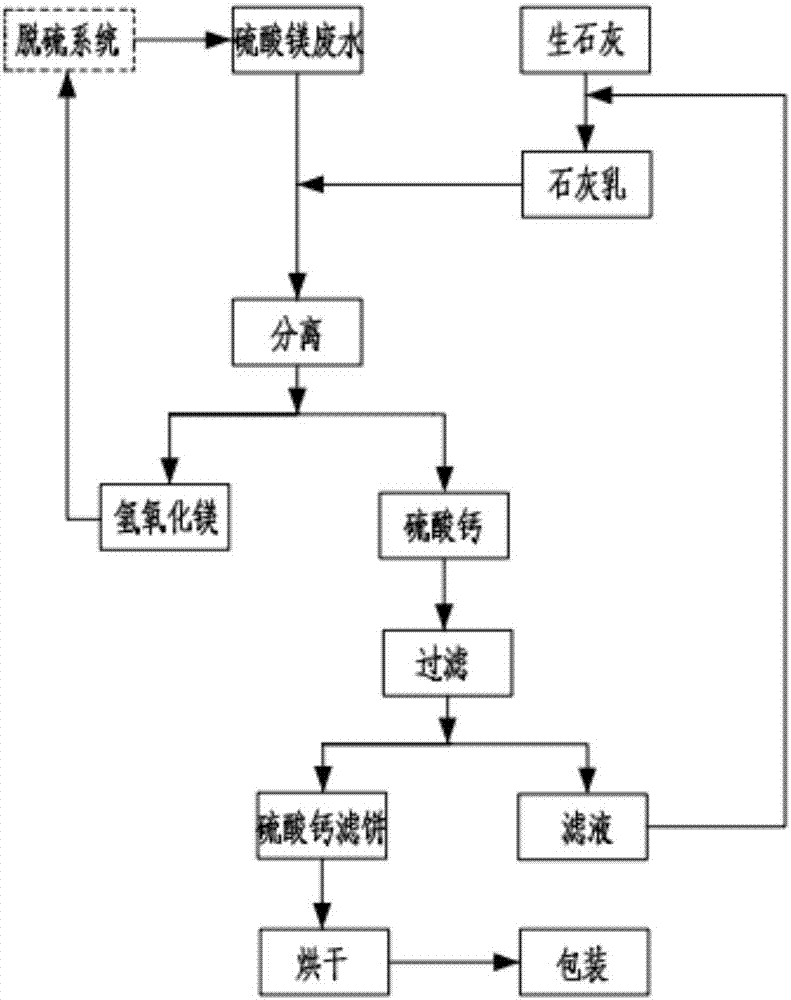

[0022] A method for treating magnesium sulfate wastewater by lime method, the steps are as follows:

[0023] Step 1: Digest the unslaked lime with a lime machine to obtain milk of lime;

[0024] Step 2: The magnesium sulfate wastewater containing 11.2% magnesium sulfate content from the boiler flue gas desulfurization system is 3 The flow rate of / h is added to the reactor, the reaction temperature is controlled to be 20°C, and then 5% milk of lime prepared in step 1 is added for reaction to obtain a slurry containing magnesium hydroxide and calcium sulfate dihydrate with a pH value of 9. material;

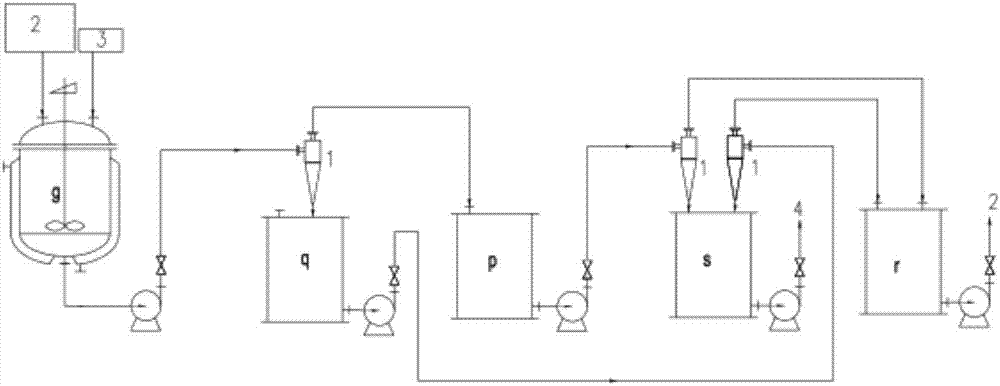

[0025] Step 3: Put the slurry that has been reacted in step 2 into the buffer of the equipment or directly pump it into the hydrocyclone for separation. The pressure at the inlet of the hydrocyclone is controlled at 0.12MPa, and the ratio of the discharge from the overflow port to the underflow port is as follows: The volume flow rate is controlled at 5:1. Most of the magnesium ...

Embodiment 2

[0031] A method for treating magnesium sulfate wastewater by lime method, the steps are as follows:

[0032] Step 1: Digest the unslaked lime with a lime machine to obtain milk of lime with a concentration of 15%;

[0033] Step 2: The magnesium sulfate wastewater containing 13.6% magnesium sulfate from the boiler flue gas desulfurization system is 3 Add the flow rate of / h in the reactor, control the reaction temperature to be 80°C, then add the milk of lime prepared in step 1 to react, and obtain a slurry containing magnesium hydroxide and calcium sulfate dihydrate with a pH value of 11.5;

[0034] Step 3: Put the slurry that has been reacted in step 2 into the buffer of the equipment or directly pump it into the hydrocyclone for separation. The pressure at the inlet of the hydrocyclone is controlled at 0.35MPa, and the ratio of the discharge from the overflow port to the underflow port is as follows: The volume flow rate is controlled at 10:1. Most of the magnesium hydroxid...

Embodiment 3

[0040] A method for treating magnesium sulfate wastewater by lime method, the steps are as follows:

[0041] Step 1: Digest the unslaked lime with a lime machine to obtain milk of lime;

[0042] Step 2: The magnesium sulfate wastewater containing 12.5% magnesium sulfate from the boiler flue gas desulfurization system is 3 Add the flow rate of / h into the reactor, control the reaction temperature to be 40°C, then add 10% milk of lime prepared in step 1 to react, and obtain a slurry containing magnesium hydroxide and calcium sulfate dihydrate with a pH value of 9.5 material;

[0043] Step 3: Put the slurry that has been reacted in step 2 into the buffer of the equipment or directly pump it into the hydrocyclone for separation. The pressure at the inlet of the hydrocyclone is controlled at 0.25MPa, and the ratio of the discharge from the overflow port to the underflow port is as follows: The volume flow rate is controlled at 7:1. Most of the magnesium hydroxide comes out of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com