Method for preparing anhydrous calcium sulfate to co-produce industrial hydrochloric acid by using pure alkali distilled waste liquid

A technology of anhydrous calcium sulfate and industrial hydrochloric acid, which is applied in the preparation of chloride, calcium/strontium/barium sulfate, chlorine/hydrogen chloride, etc., can solve the problems of low economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

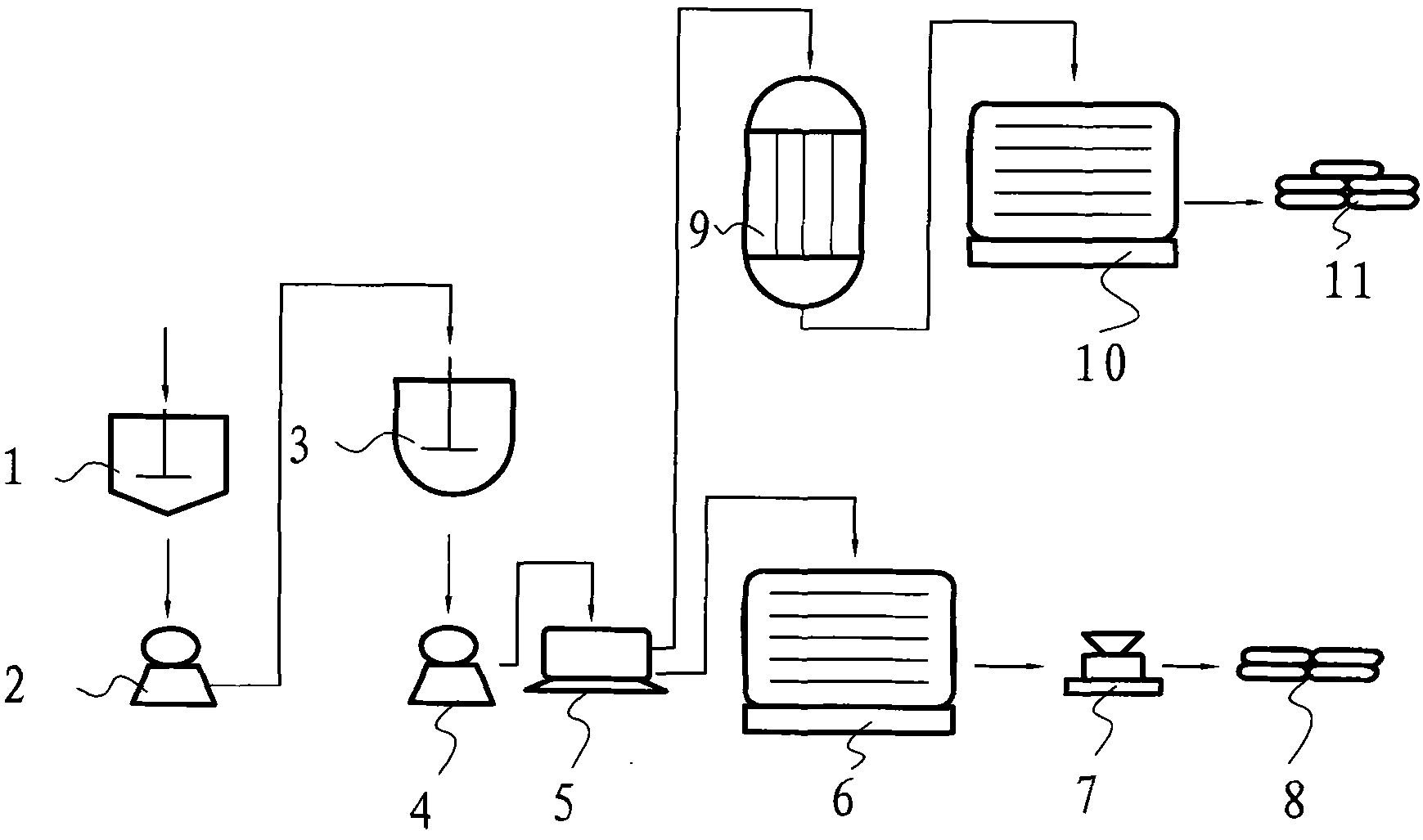

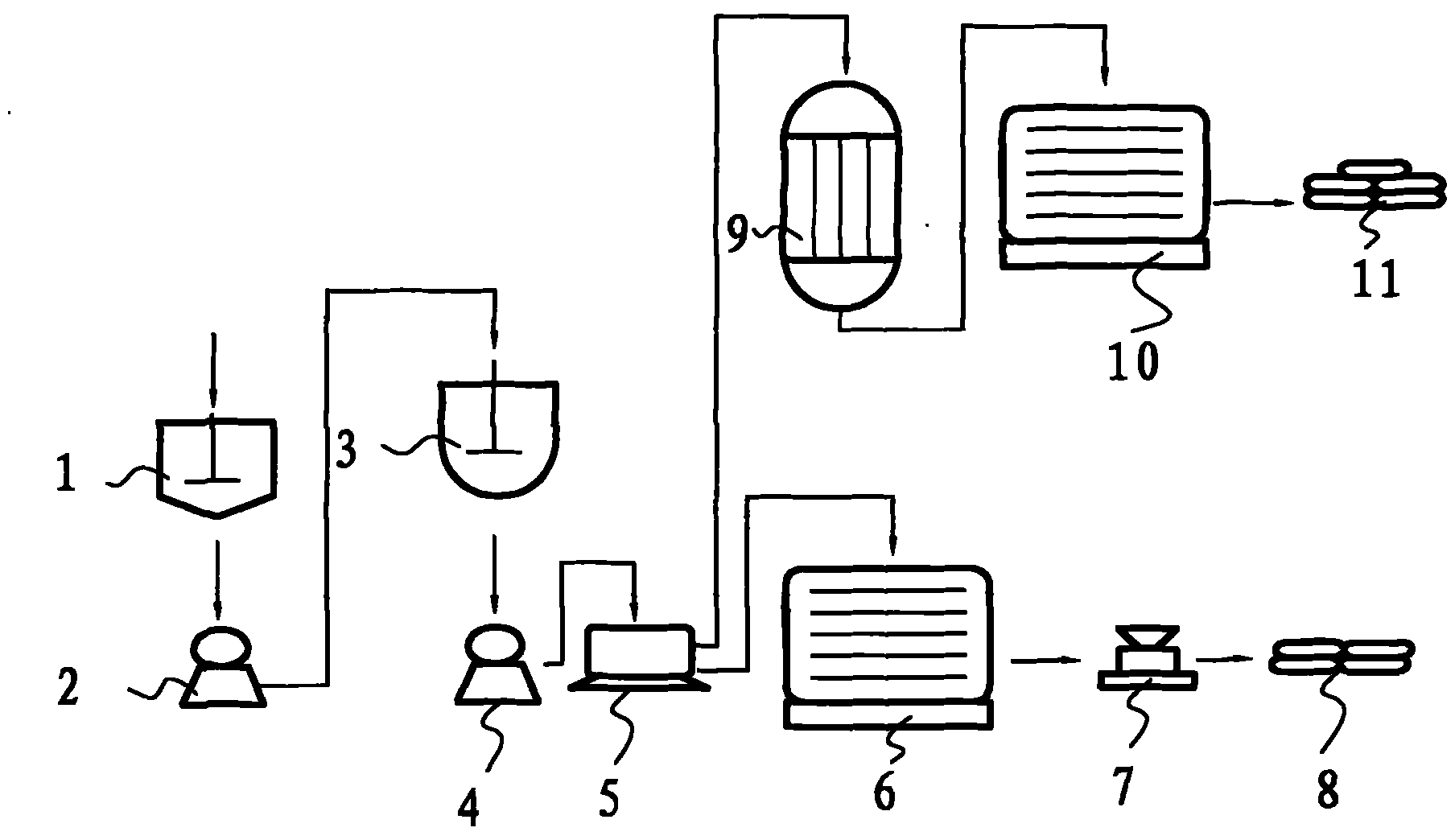

Embodiment 1

[0019] Prepare the method for anhydrous calcium sulfate co-production industrial hydrochloric acid with soda ash distillation waste liquid, 500kg soda ash distillation waste liquid containing calcium salt 12% and hydrochloric acid are put into purifier 1 according to the mass ratio of pure substance 1: 0.53 and carry out purification reaction, The reaction generates 33.60kg of calcium chloride-based solution, which is filtered with a suction filter-2, and the insoluble filter cake impurities are burned or buried, and the clarified calcium chloride filtrate plus the original solution adds up to 286.09kg of pure calcium chloride The clarified calcium chloride solution is put into the synthesizer 3 with sulfuric acid according to the mass ratio of pure substance 1: 0.68 to carry out the synthesis reaction, and the reaction generates a mixed solution of calcium sulfate dihydrate and hydrochloric acid, and the reaction product is filtered with a suction filter. Carry out suction fil...

Embodiment 2

[0021] The method for preparing anhydrous calcium sulfate co-production industrial hydrochloric acid with soda ash distillation waste liquid, puts the soda ash distillation waste liquid containing 13% of calcium salt and hydrochloric acid into purifier 1 according to the mass ratio of pure substance 1:0.73 for purification reaction, the reaction Generate 72.15kg of calcium chloride-based solution, use suction filter-2 to carry out suction filtration, burn or bury insoluble filter cake impurities, and clarify the calcium chloride filtrate plus 207.15kg of pure calcium chloride in the original solution to clarify Calcium chloride solution, then put into synthesizer 3 with sulfuric acid according to the mass ratio of pure substance 1: 0.88 to carry out synthesis reaction, the reaction generates the mixed solution of calcium sulfate dihydrate and hydrochloric acid, and the reaction product is carried out with suction filter 2 4 Suction filtration, the white filter cake obtained by ...

Embodiment 3

[0023] The method for preparing anhydrous calcium sulfate co-production industrial hydrochloric acid with soda ash distillation waste liquid, puts the soda ash distillation waste liquid containing 15% of calcium salt and hydrochloric acid into purifier 1 according to the mass ratio of pure substance 1:0.93 for purification reaction, the reaction Generate 106.06kg of calcium chloride-based solution, filter with suction filter 1-2, burn or bury the insoluble filter cake impurities, and add 141.06kg of pure calcium chloride in the clarified calcium chloride filtrate to the original solution to clarify Calcium chloride solution, then put into synthesizer 3 with sulfuric acid according to the mass ratio of pure substance 1: 1.08 to carry out synthesis reaction, the reaction generates the mixed solution of calcium sulfate dihydrate and hydrochloric acid, and the reaction product is carried out with suction filter 2 4 Suction filtration, the white filter cake obtained by suction filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com