Clean production method and device of dinitrotoluene

A dinitrotoluene and clean production technology, which is applied in the direction of nitro compound preparation, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of large energy consumption, high recycling cost, and long time, so as to save resources, The effect of reducing reaction time and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

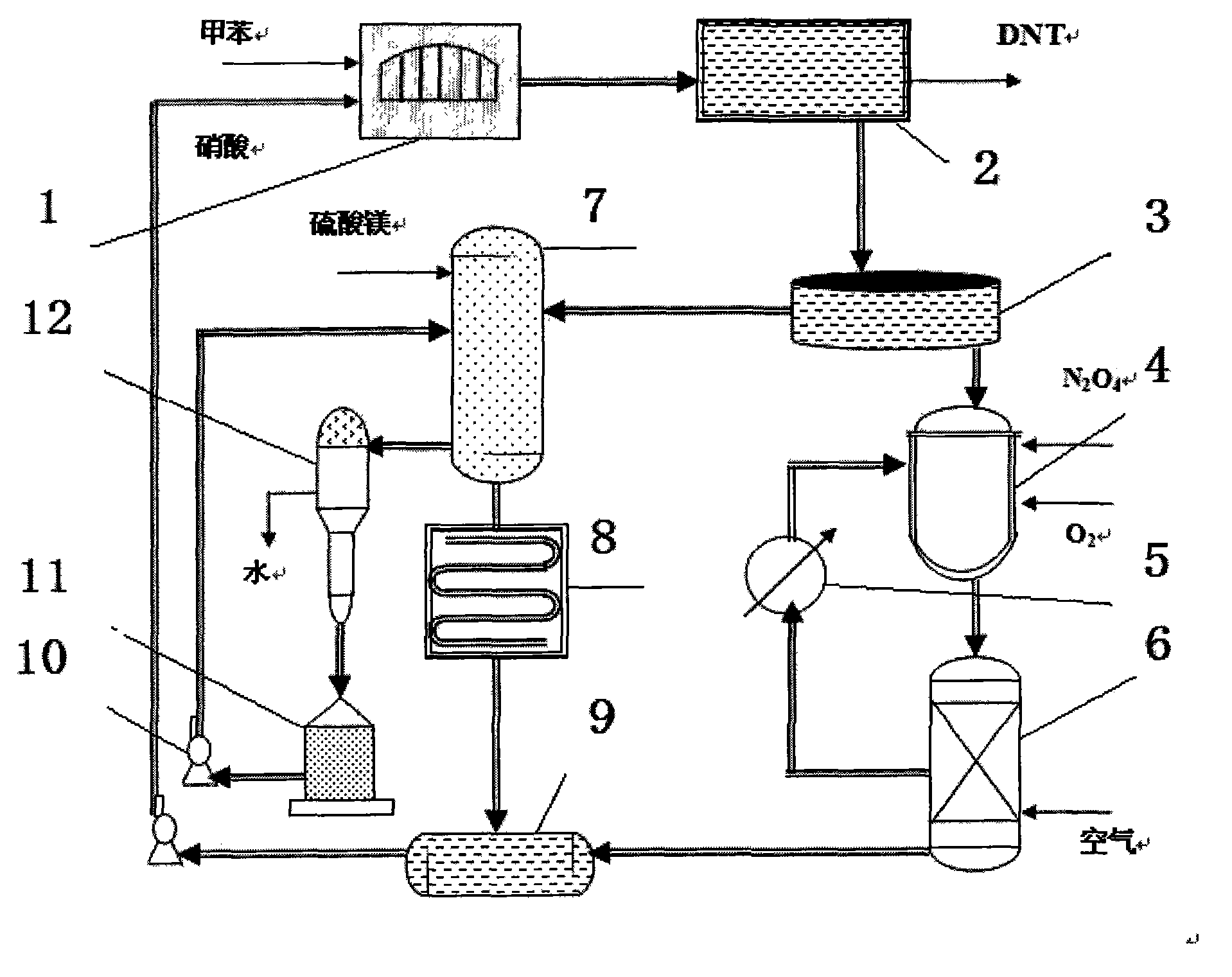

[0040] A kind of dinitrotoluene clean production method, concrete steps are as follows:

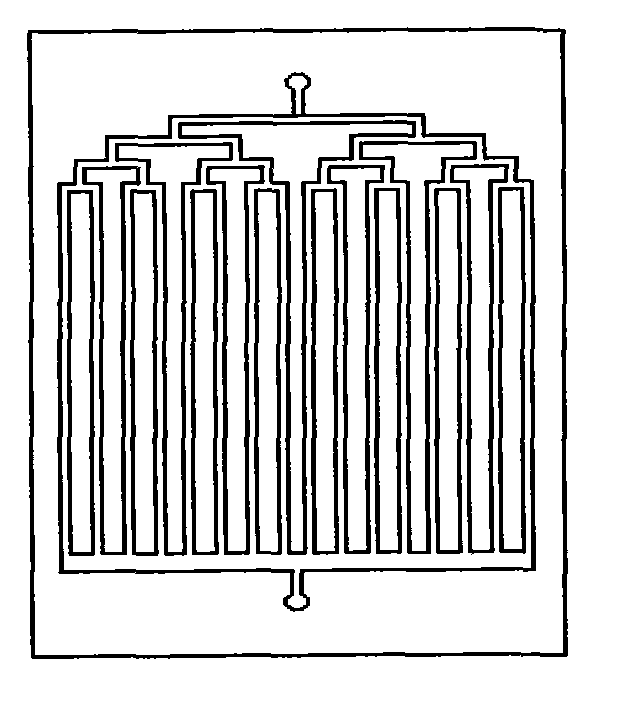

[0041] Step one, nitrification

[0042] With toluene and the nitric acid that concentration is 90% as raw material, under the condition that toluene and nitric acid feeding ratio are 1: 5, carry out nitration reaction by microreactor 1, microreactor 1 structure schematic diagram is as figure 2 As shown, the residence time of the material in the microreactor 1 is controlled at 8s, the reaction temperature is 58°C, and DNT and HNO are obtained after nitration 3 and H 2 0 mixed solution;

[0043] Step 2. Separation

[0044] The crude mixed solution of dinitrotoluene and dilute nitric acid obtained in step 1 is separated from dinitrotoluene and dilute nitric acid through a fiber bed liquid-liquid phase separator at 55° C. to obtain dinitrotoluene products and dilute nitric acid Nitric acid, the measured dinitrotoluene product purity is 94.6%, the yield is 92%, and the concentration of dilu...

Embodiment 2

[0052] A kind of dinitrotoluene clean production method, concrete steps are as follows:

[0053] Step one, nitrification

[0054] Toluene and concentration are the nitric acid of 93% as raw material, under the condition that toluene and nitric acid feed ratio are 1: 6, carry out nitration reaction by microreactor 1, the residence time of material in microreactor 1 is controlled at 10s, reaction Temperature: 60°C, DNT and HNO are obtained after nitration 3 and H 2 0 mixed solution;

[0055] Step 2. Separation

[0056] The crude mixed solution of dinitrotoluene and dilute nitric acid obtained in step 1 is separated from dinitrotoluene and dilute nitric acid through a fiber bed liquid-liquid phase separator at 57° C. to obtain dinitrotoluene products and dilute nitric acid Nitric acid, the measured dinitrotoluene product purity is 95.6%, the yield is 93%, and the concentration of dilute nitric acid produced is 88.51%;

[0057] Step 3. Concentrate or Concentrate

[0058] Con...

Embodiment 3

[0060] A kind of dinitrotoluene clean production method, concrete steps are as follows:

[0061] Step one, nitrification

[0062] With toluene and the nitric acid that concentration is 95% as raw material, under the condition that toluene and nitric acid feed ratio are 1: 7, carry out nitration reaction by microreactor 1, the residence time of material in microreactor 1 is controlled at 12s, reaction Temperature: 60°C, DNT and HN0 are obtained after nitration 3 and H 2 0 mixed solution;

[0063] Step 2. Separation

[0064] The crude mixed solution of dinitrotoluene and dilute nitric acid obtained in step 1 is separated from dinitrotoluene and dilute nitric acid through a fiber bed liquid-liquid phase separator at 58 ° C to obtain dinitrotoluene products and dilute nitric acid Nitric acid, the measured dinitrotoluene product purity is 91.2%, the yield is 91%, and the concentration of dilute nitric acid produced is 89.92%;

[0065] Step 3. Concentrate or Concentrate

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com