Crushing and sorting device for electronic waste recycling

A sorting device, a technology for electronic waste, applied in the directions of magnetic separation, solid separation, sieve, etc., can solve the problems of difficult to clean, heavy labor, low work efficiency, etc., to improve crushing efficiency, high degree of automation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

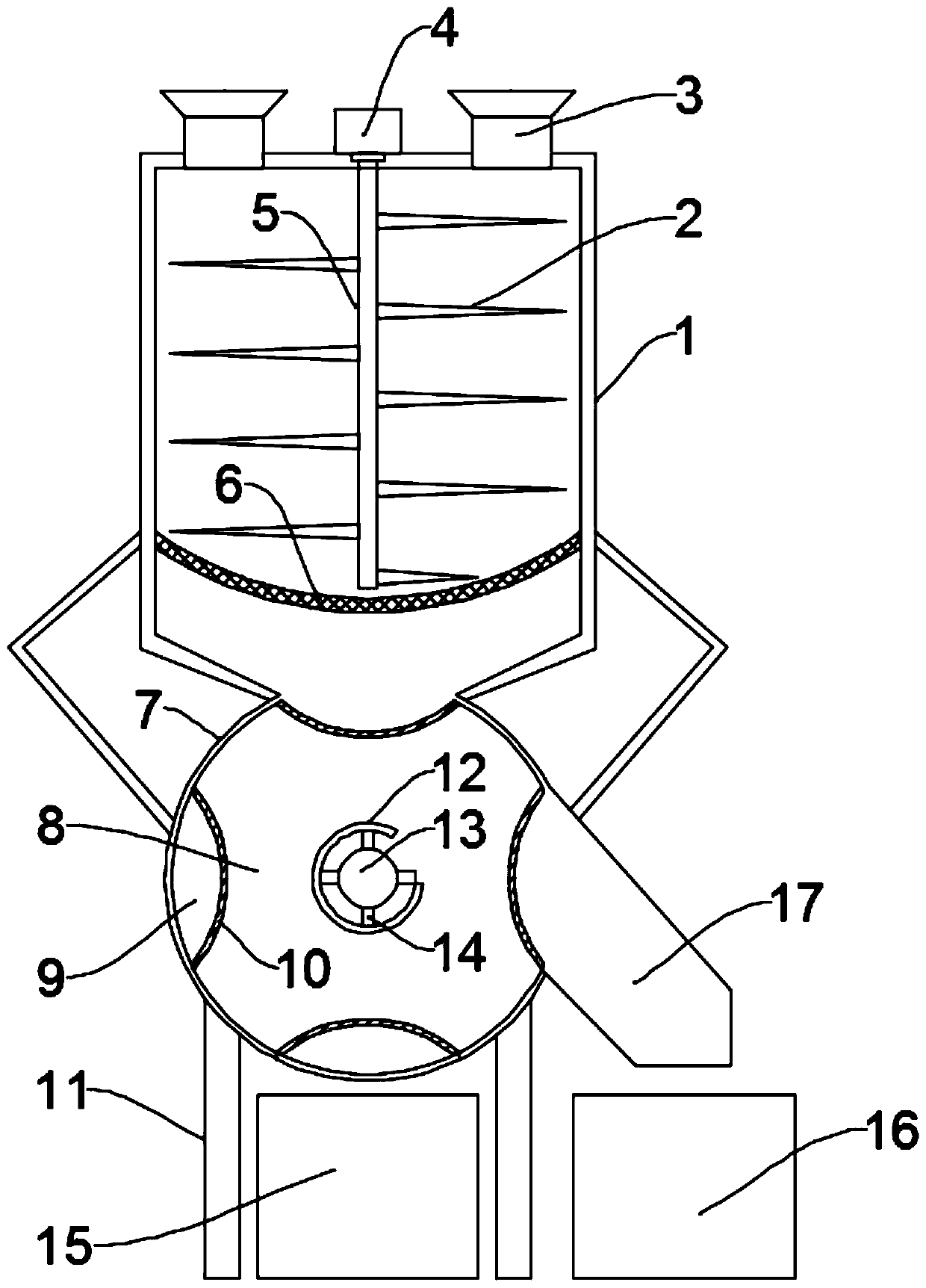

[0023] see figure 1 , in an embodiment of the present invention, a crushing and sorting device for recycling electronic waste includes a crushing mechanism and a sorting mechanism, the crushing mechanism is located above the sorting mechanism, and the crushing mechanism includes a crushing cylinder 1, a first motor 4, Rotating shaft 5, crushing knife 2 and metal screen 6, both sides of the top of the crushing cylinder 1 are provided with feed hoppers 3, the first motor 4 is installed in the middle of the top of the crushing cylinder 1, and the output shaft of the first motor 4 passes through the shaft coupling The device is fixedly connected with the rotating shaft 5, the rotating shaft 5 is located in the crushing cylinder 1, and a plurality of crushing knives 2 are welded and fixed on the rotating shaft 5 at equidistant intervals. Screen 6, the metal screen 6 is fixedly connected to the inner wall of the crushing cylinder 1, the sorting mechanism includes a sorting cylinder ...

Embodiment 2

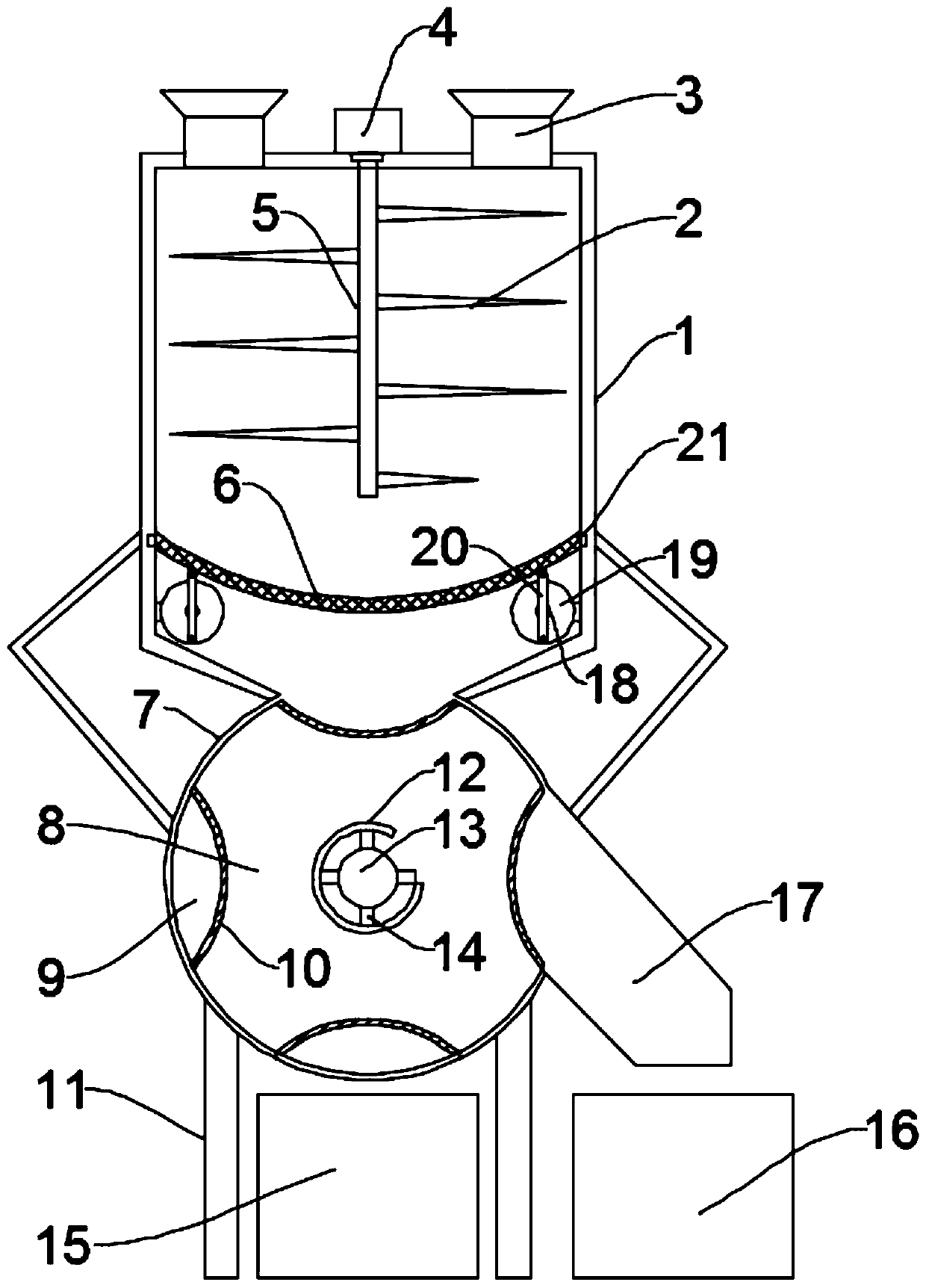

[0025] see figure 2 The difference between the embodiment of the present invention and embodiment 1 is that the metal screen 6 is slidably connected to the inner wall of the crushing cylinder 1 through a slider 21, and drive motors 18 are installed on both sides of the bottom of the metal screen 6 to drive The end of the output shaft of the motor 18 is equipped with a disc 19, the outer side of the front end of the disc 19 is hinged with a connecting rod 20, the other end of the connecting rod 20 is hinged with the bottom of the metal screen 6, the drive motor 18 is started, and the drive motor 18 drives the disc 19 Rotate, the disc 19 drives the metal screen 6 to move up and down through the connecting rod 20, the distance between the lowest point of the metal screen 6 and the bottom end of the rotating shaft 5 is greater than the diameter of the disc 19, ensuring that the metal screen 6 and the rotating shaft 5 do not interfere with each other, and the metal screen When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com