Method for degrading polybrominated diphenyl ethers using surface active agent solubilization combined with UV technique

A technology of surfactants and polybrominated diphenyl ethers, applied in the field of degrading polybrominated diphenyl ethers, to achieve the effect of not easy to adsorb, easy to obtain, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

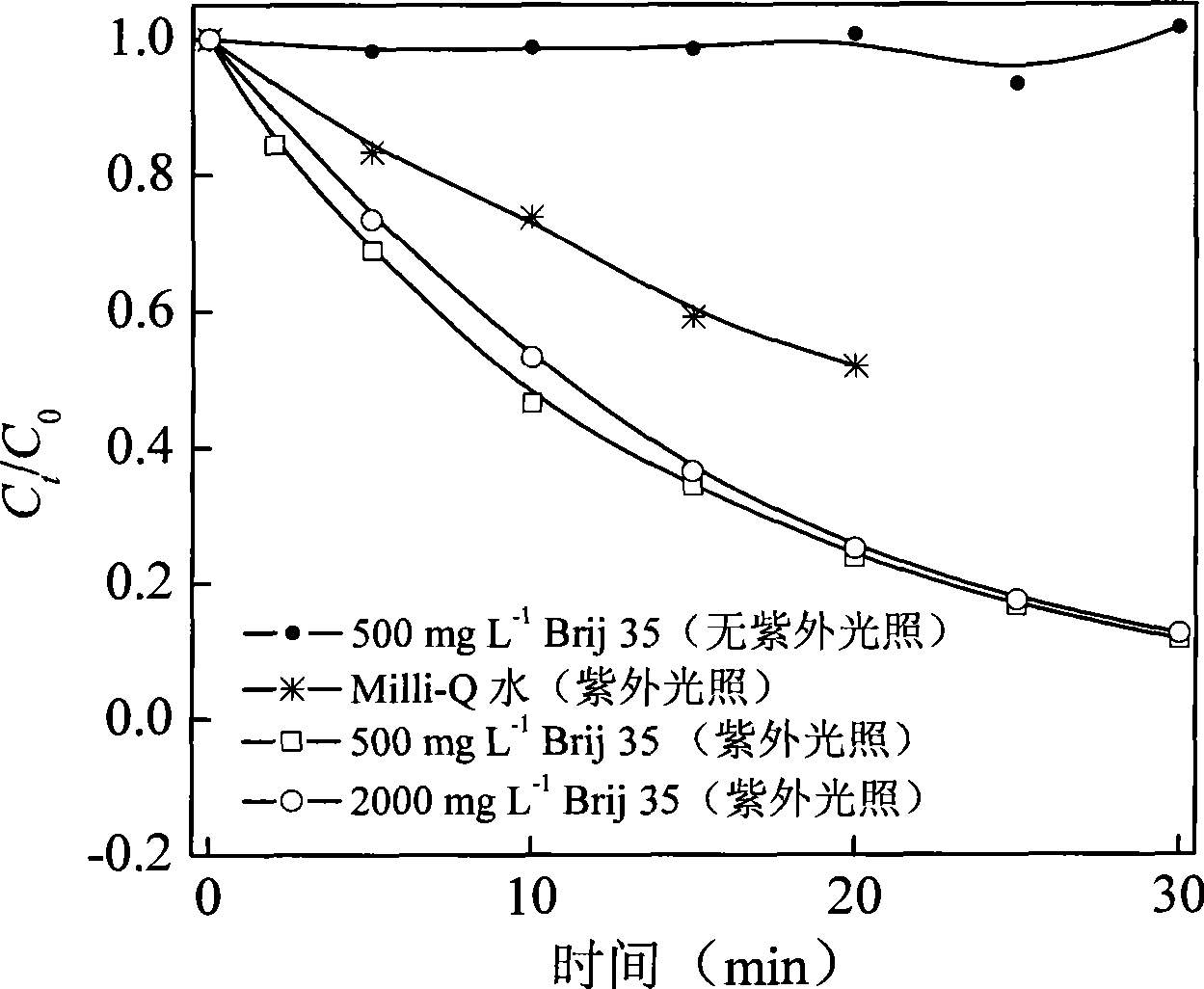

[0046] Example 1: Photolysis of BDE-99 in Brij 35 Micellar Solution

[0047] The Brij 35 used in the present invention was purchased from Amresco Company in the United States, and some of its physical and chemical properties are shown in Table 1. Brij 35 molecular monomer uses dodecyl chain as hydrophobic group, and polyoxyethylene ether chain with polymerization degree of 23 is hydrophilic group, and the concentration of surfactant is about 192mg L -1 form micelles.

[0048] Take 500 μL of BDE-99 solution (5 mg L dissolved in n-hexane) -1 ), put it into a 50mL brown volumetric flask, pass high-purity nitrogen (99.999%) to dry n-hexane gently, and make BDE-99 adhere to the bottom of the volumetric flask in solid form. Add 500 or 2000mg L -1 The Brij 35 solution reached the scale line of the volumetric flask; under the conditions of normal temperature and pressure and protected from light, the brown volumetric flask was solubilized in a water bath ultrasonic device, the outp...

Embodiment 2

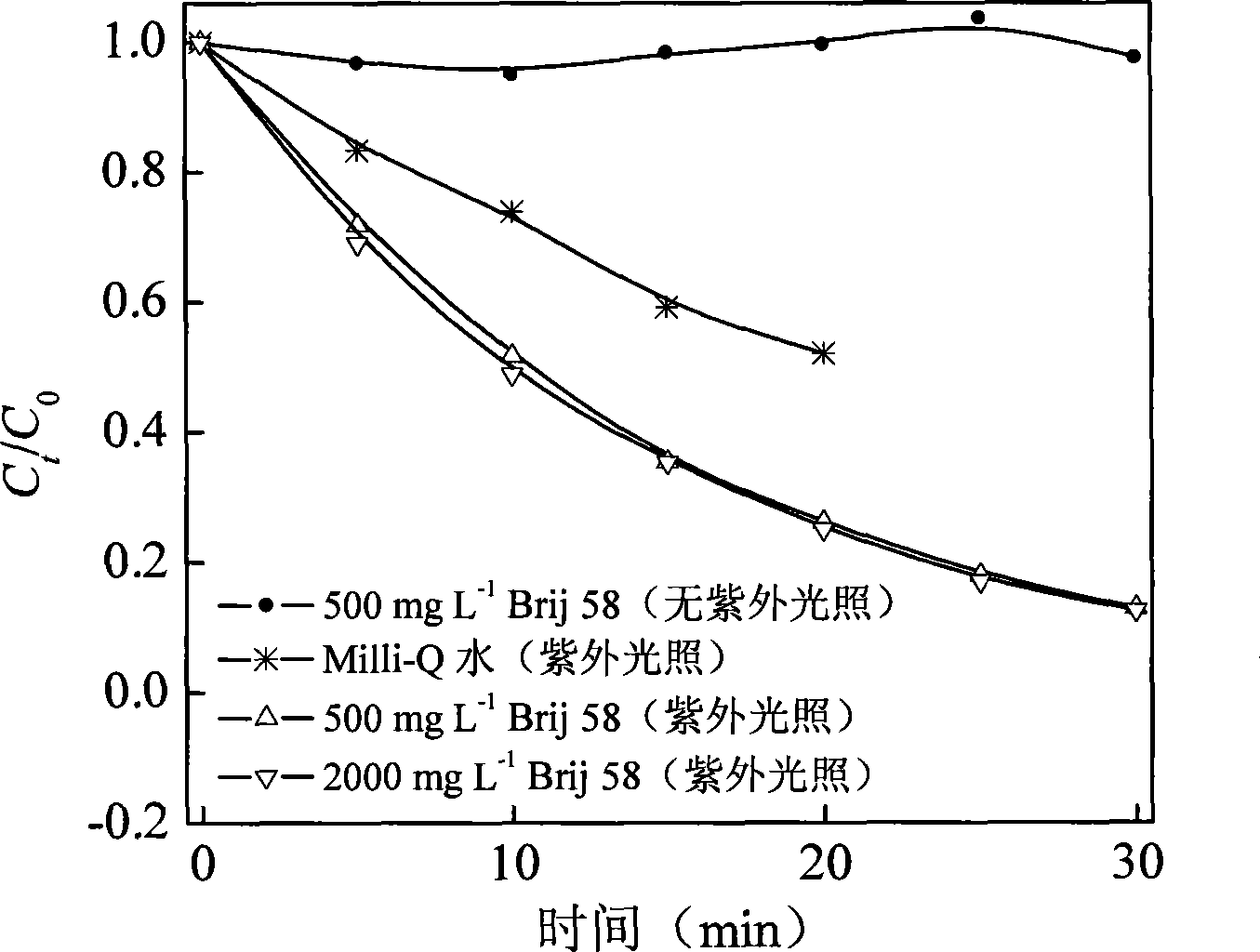

[0051] Example 2: Photolysis of BDE-99 in Brij 58 Micellar Solution

[0052] Brij 58 used in the present invention was purchased from Sigma Company in the United States, and some of its physical and chemical properties are shown in Table 1. Brij 58 molecular monomer uses hexadecyl chain as hydrophobic group, and polyoxyethylene ether chain with polymerization degree of 20 is hydrophilic group, and the concentration of surfactant is about 90mg L -1 form micelles.

[0053] Take 500 μL of BDE-99 solution (5 mg L dissolved in n-hexane) -1 ), put it into a 50mL brown volumetric flask, pass high-purity nitrogen (99.999%) to dry n-hexane gently, and make BDE-99 adhere to the bottom of the volumetric flask in solid form. Add 500 or 2000mg L -1 The Brij 58 solution reached the scale line of the volumetric flask. Under the conditions of normal temperature and pressure and protected from light, the brown volumetric flask was solubilized in a water bath ultrasonic device. The output po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com