Method for preparation of ultrafine copper powder by waste circuit board copper dissolution-electrodeposition combined method

A technology for discarded circuit boards and ultrafine copper powder, which is applied in the field of electronic waste recycling, and can solve problems such as incomplete separation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

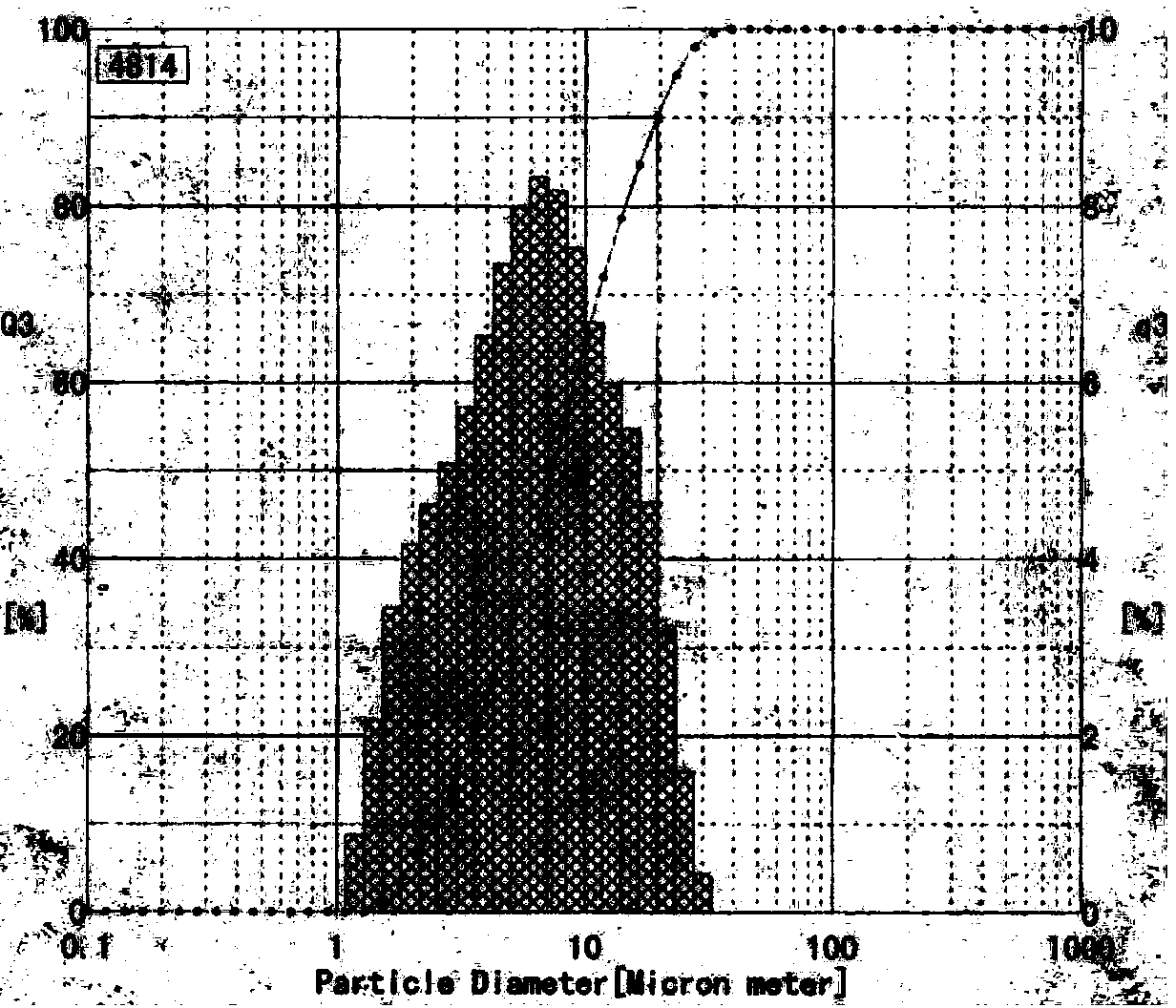

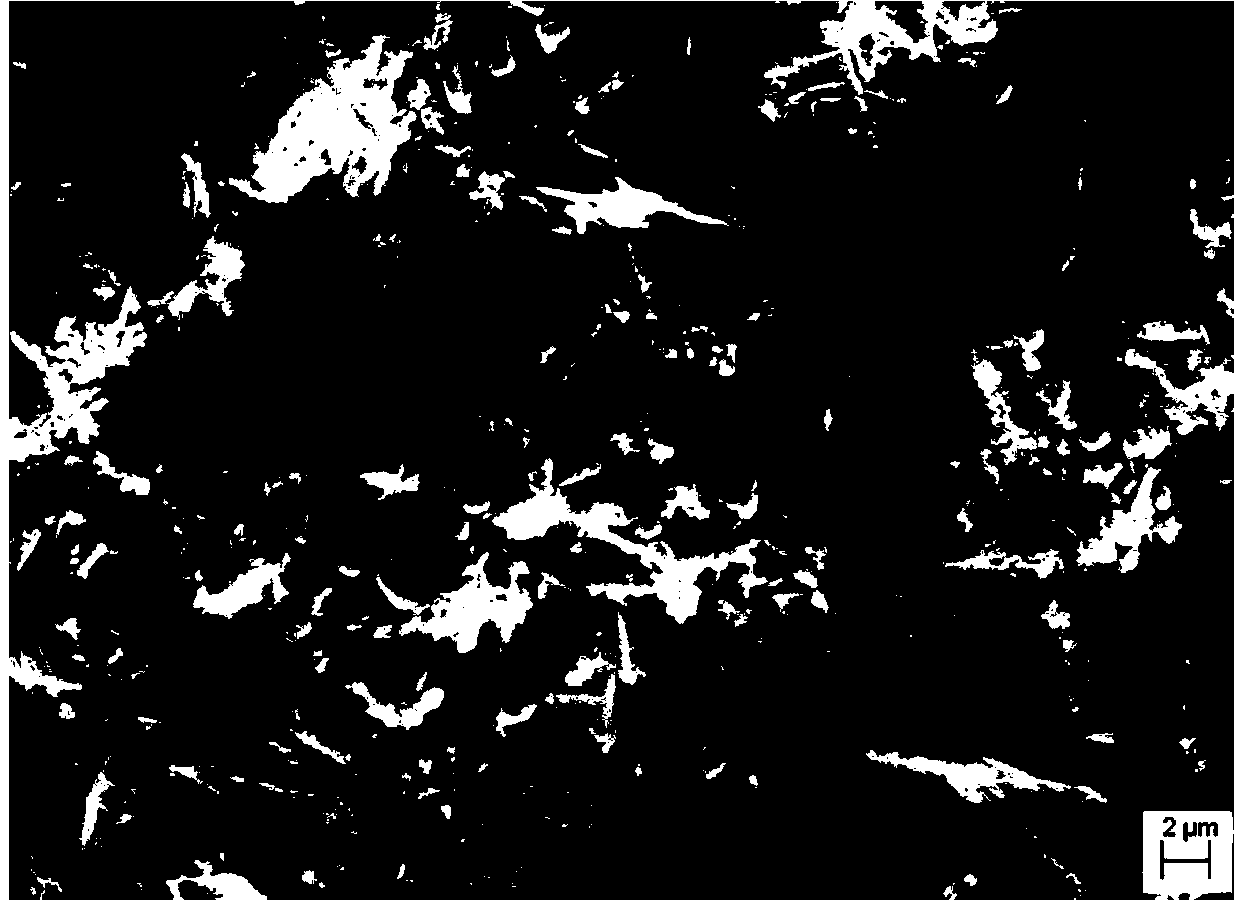

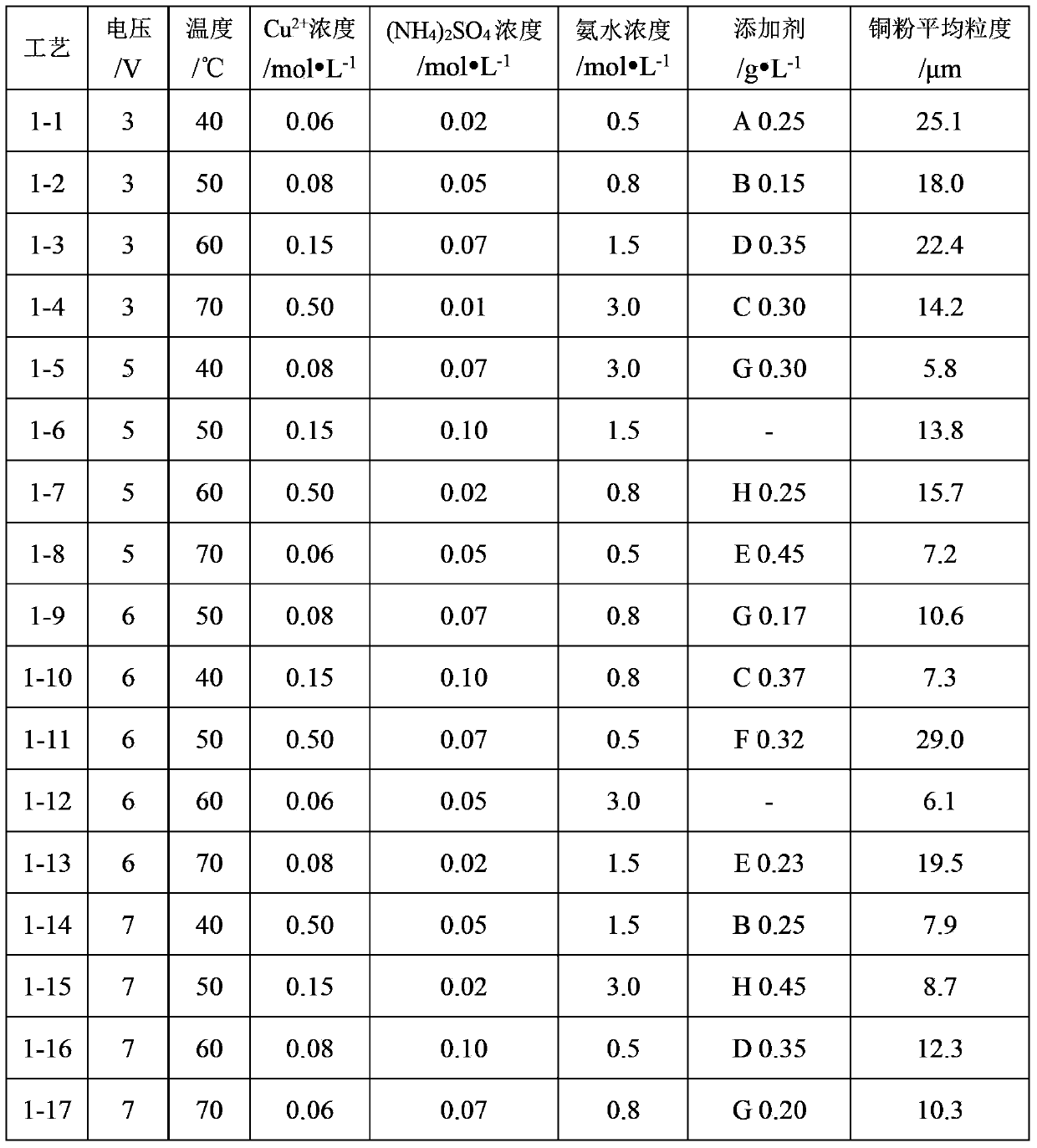

[0026] Put the prepared electrolyte into the electrolytic cell, put the discarded circuit board after the paint removal in the anode area, pass nitrogen gas through the cathode, the temperature of the electrolyte is 30-70°C, the magnetic stirring speed is 100-300r / min, DC electrolysis to obtain ultra-fine copper powder. The specific electrolysis conditions and the average particle size of the obtained copper powder are shown in Table 1 (the additives are Tween, sodium dodecylbenzenesulfonate, isooctylphenol polyoxyethylene ether, cetyltrimethylammonium bromide, sulfobeet alkali, lauryl amidopropyl hydroxysultaine, decyl glucoside and disodium edetate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com