Method for preparing building material by using phosphogypsum

A building material, phosphogypsum technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low strength and poor durability, achieve high strength, overcome poor water resistance, and realize functionalization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

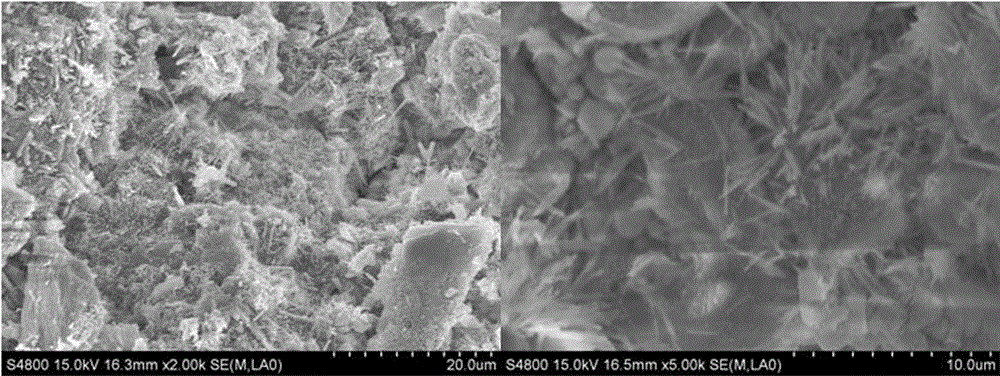

Image

Examples

Embodiment 1

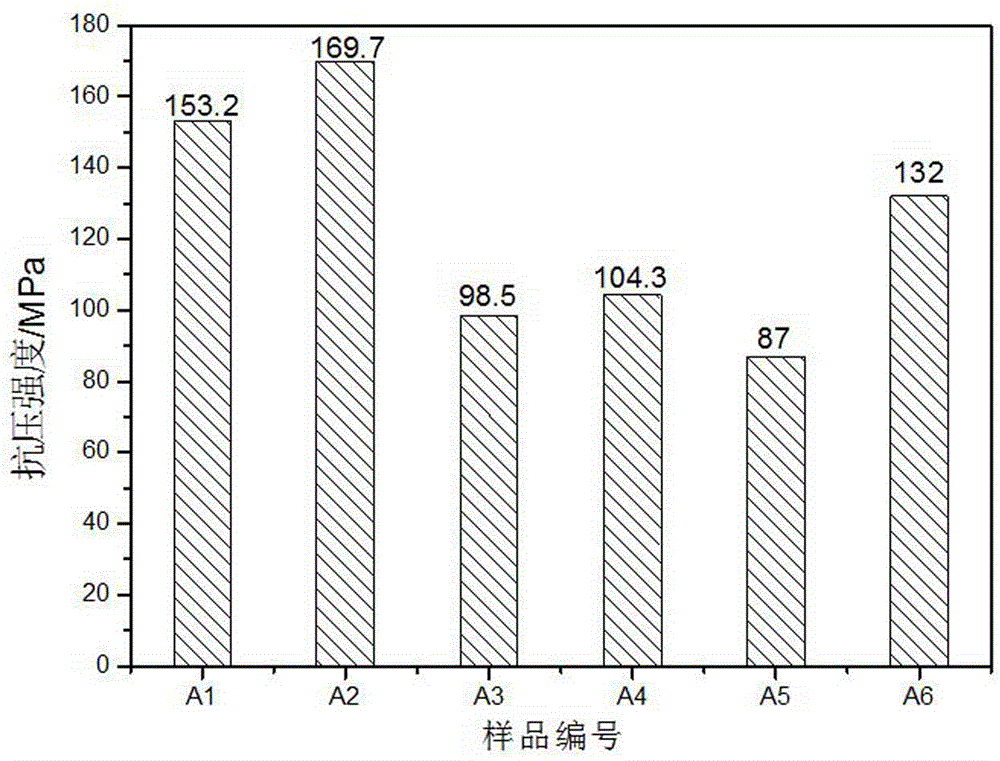

[0036] The specific surface area will be 450 m 2 / kg phosphogypsum 400g (40%), specific surface area 600 m 2 / kg water-quenched granulated blast furnace slag 300g (30%), specific surface area 380 m 2 / kgP·O4 50g (5%) of cement and 250g (25%) of river sand with a fineness modulus of 2.4 are dry mixed in a mixer for 3 minutes; then add 150g of water (15% of the dry mass of all solid materials) , an additional 1.5g of alkaline activator (accounting for 0.5% of the water-quenched granulated blast furnace slag powder) was added to the water, and wet mixed for 10 minutes; after standing for 15 minutes, the pressure was maintained at 40MPa for 30s to obtain a super-strong material body; Indoor natural conservation for 28 days to obtain ultra-high-strength building materials A 1 , after standing still for 1 hour, cured in saturated steam at 80°C for 9 hours, the super-high-strength building material A was obtained 2 , compressive strength see figure 2 .

Embodiment 2

[0038]Put 2500g of phosphogypsum with a moisture content of 8% and 2500g of water-quenched ferronickel slag into a 500×500mm standard ball mill for grinding for 58 minutes to obtain a specific surface area of 624 m 2 / kg of mixture, take 620g of mixture (dry phosphogypsum accounts for 29% of the total dry basis material, water-quenched ferronickel slag accounts for 32% of the total dry basis material), and the specific surface area is 380 m 2 / kg P·O4 2.5 cement 60g (accounting for 6.2% of the total dry basis material) and 320g of river sand with a fineness modulus of 2.4 (accounting for 32.8% of the total dry basis material) are dry mixed in the mixer for 4min; then add 150g of water (plus the water brought in by gypsum accounts for 17.9% of the total dry basis material), add an additional 1.8g of alkaline activator (accounting for 0.6% of the water-quenched ferronickel slag powder) in the water, wet mix for 8 minutes; stand for 30 minutes After holding the pressure at 45MP...

Embodiment 3

[0040] Put 2800g of phosphogypsum with a moisture content of 6% and 2200g of water-quenched manganese slag into a 500×500mm standard ball mill for grinding for 67 minutes to obtain a specific surface area of 650 m 2 / kg of mixture, take 670g of mixture (dry phosphogypsum accounts for 36.1% of the total dry basis material, water-quenched manganese slag accounts for 30.1% of the total dry basis material), and the specific surface area is 380 m 2 / kg P·O4 2.5 cement 90g (accounting for 9.2% of the total dry basis material) and 240g of machine-made sand with a fineness modulus of 3.2 (accounting for 24.6% of the total dry basis material) are dry mixed in the mixer for 3min; then add 140g of water (plus the water brought in by gypsum accounted for 16.6% of the total dry material), added an additional 1.4g of alkaline activator (accounting for 0.47% of the water-quenched manganese slag powder) to the water, wet mixed for 9 minutes; after standing for 30 minutes Hold the pressure a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com