Zero-discharge treatment method of desulfurization waste water

A technology for desulfurization wastewater and treatment methods, which is applied in the field of wastewater treatment, can solve problems such as water body impact, and achieve the effect of reducing scaling tendency and avoiding scaling or corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

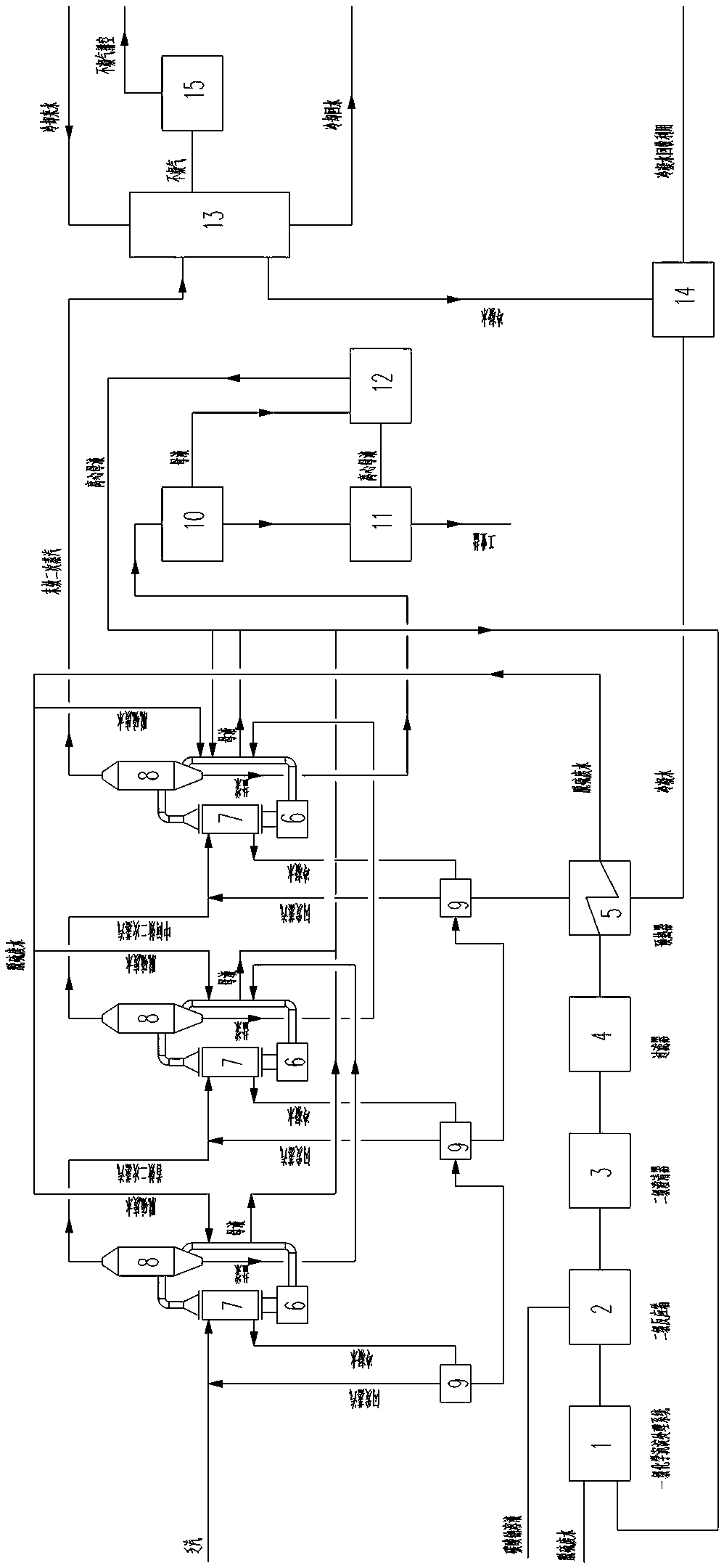

[0036] Such as figure 1 As shown, a zero-discharge treatment method for desulfurization wastewater includes the following steps: after the desulfurization wastewater is treated by a first-level chemical precipitation treatment system 1, sodium carbonate is added to the desulfurization wastewater for reaction, and then the desulfurization wastewater is precipitated and filtered. Evaporation by the multi-effect evaporator, the steam produced by evaporation is heat-exchanged to obtain condensed water, the salt slurry produced by evaporation enters the solid-liquid separation device for solid-liquid separation, and solid salt is obtained, and the scaling ions of the mother liquor in the multi-effect evaporator Before the concentration reaches the scaling concentration or the concentration of corrosion ions reaches the concentration of corrosion heat exchange tubes, part of the mother liquor in the multi-effect evaporator is introduced into the first-level chemical precipitation tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com