Preparation method of ultra-pure and ultrafine silver nanowire

A nanowire and ultra-fine silver technology, applied in the field of nanowire materials, can solve the problems that cannot meet the requirements of the display screen for transparent conductive films, the transparent conductive film has a large haze, and the purification effect is not good, so as to achieve the reduction of hydroxide radicals The effect of plasma concentration, low cost, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

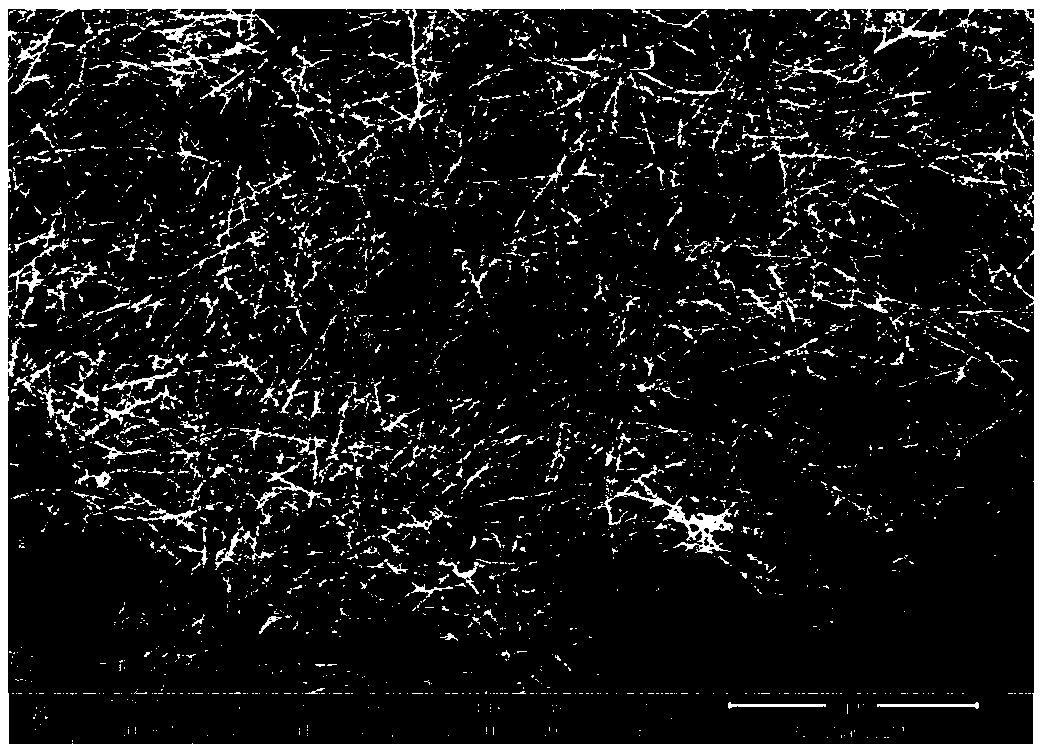

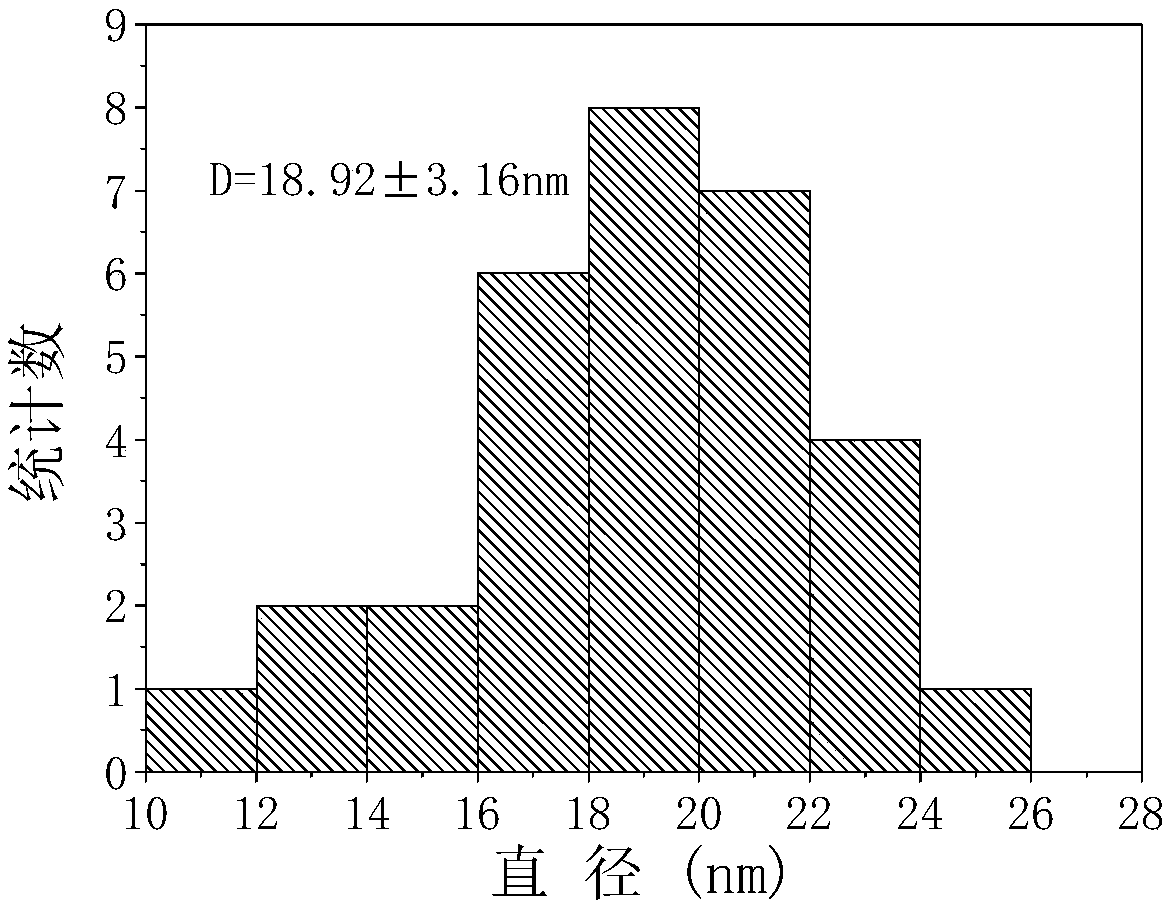

[0026] The method for preparing ultra-pure and ultra-fine silver nanowires of the present invention removes moisture in ethylene glycol by heating, regulates the size of the initial crystal nucleus, and after 30min-180min of heat preservation, nanowires with a diameter of 15nm-25nm can be obtained. Ultra-pure and ultra-fine silver nanowires with a mass percentage of 75%-95%.

[0027] Specifically include the following steps:

[0028] (1) Preparation of sodium bromide in ethylene glycol solution: Weigh a certain amount of sodium bromide and dissolve it in ethylene glycol, stir and dissolve on a heating plate at 100°C-150°C for 1min-180min, and the concentration is 1mM- 1000mM;

[0029] (2) Preparation of ethylene glycol solution of sodium chloride: Weigh a certain amount of sodium chloride and dissolve it in ethylene glycol, stir and dissolve on a heating plate at 100°C-150°C for 1min-180min, and the concentration is 1mM- 1000mM;

[0030] (3) Preparation of PVP ethylene glyc...

Embodiment 1

[0034] (1) Preparation of sodium bromide in ethylene glycol solution: weigh 0.4572g of sodium bromide and dissolve in 20mL of ethylene glycol, stir and dissolve on a heating plate at 130°C for 2h;

[0035] (2) Preparation of ethylene glycol solution of sodium chloride: Weigh 0.2466g of sodium chloride and dissolve in 20mL of ethylene glycol, stir and dissolve on a heating plate at 130°C for 2 hours;

[0036] (3) Preparation of PVP ethylene glycol solution: weigh 1.68g of PVP with a molecular weight of 360,000, dissolve it in 30mL of ethylene glycol, and stir and dissolve it on a heating plate at 130°C for 5 minutes;

[0037] (4) Preparation of ethylene glycol solution of silver nitrate: Weigh 15mL of ethylene glycol, stir on a heating plate at 130°C for 2 hours, cool to room temperature in a drying oven, weigh 0.6765g of silver nitrate, dissolve it in In the above-mentioned ethylene glycol, sonicate for 5 minutes in an ice-water bath at a temperature of 5°C in an ultrasonic in...

Embodiment 2

[0040] On the basis of Example 1, just change step (5) to take 116mL of ethylene glycol and pour it into a 250mL round bottom flask, stir and heat at 130°C in an oil bath for 120min, then add step (1)- (4) For the prepared solution, the molar ratio of silver nitrate, sodium bromide, sodium chloride and PVP is 10:1:1:10, the temperature is raised to 180°C, and the temperature is lowered to 160°C after the temperature stabilizes , and keep it warm for 60 minutes to obtain ultra-pure and ultra-fine silver nanowires with a diameter of 24 nm and a mass percentage of 89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com