Treatment process and device of industrial wastewater containing heavy metal ions

A technology for heavy metal ions and industrial wastewater, which is applied in the field of water treatment, can solve the problems of unstable discharge water quality, high concentration of heavy metal ions in effluent, and difficulty in achieving efficient and deep removal of wastewater containing heavy metal ions, so as to ensure water quality and stability and occupy an area The effect of small area and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] lab test

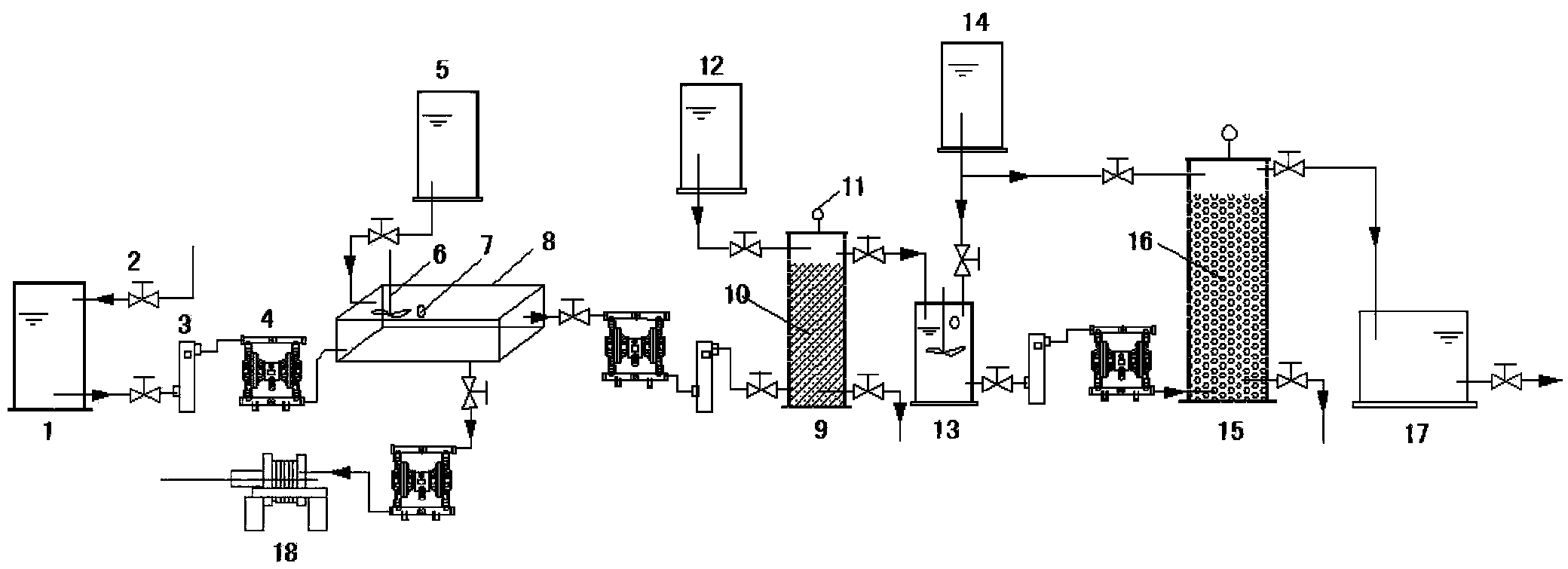

[0030] The device used: a lead-containing wastewater treatment device includes: raw water tank 1, valve 2, flow meter 3 is not provided in this embodiment, water pump 4, alkali tank 5, agitator 6, pH probe 7, reaction sedimentation tank 8, Filtration tower 9, filter material 10, pressure gauge 11 is not provided in this embodiment, tap water tank 12, intermediate pool 13, acid tank 14, adsorption tower 15, polymer hydrogel adsorption material 16, clean water tank 17, filter press 18 is not set in this embodiment.

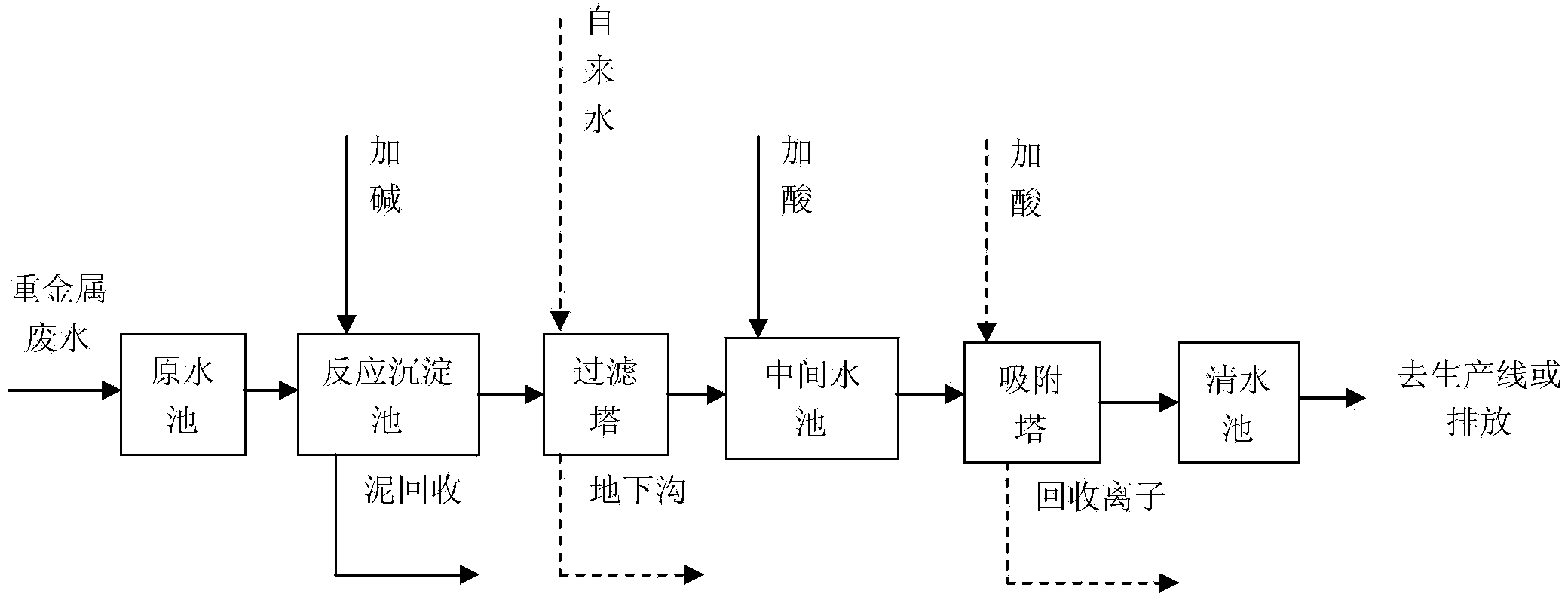

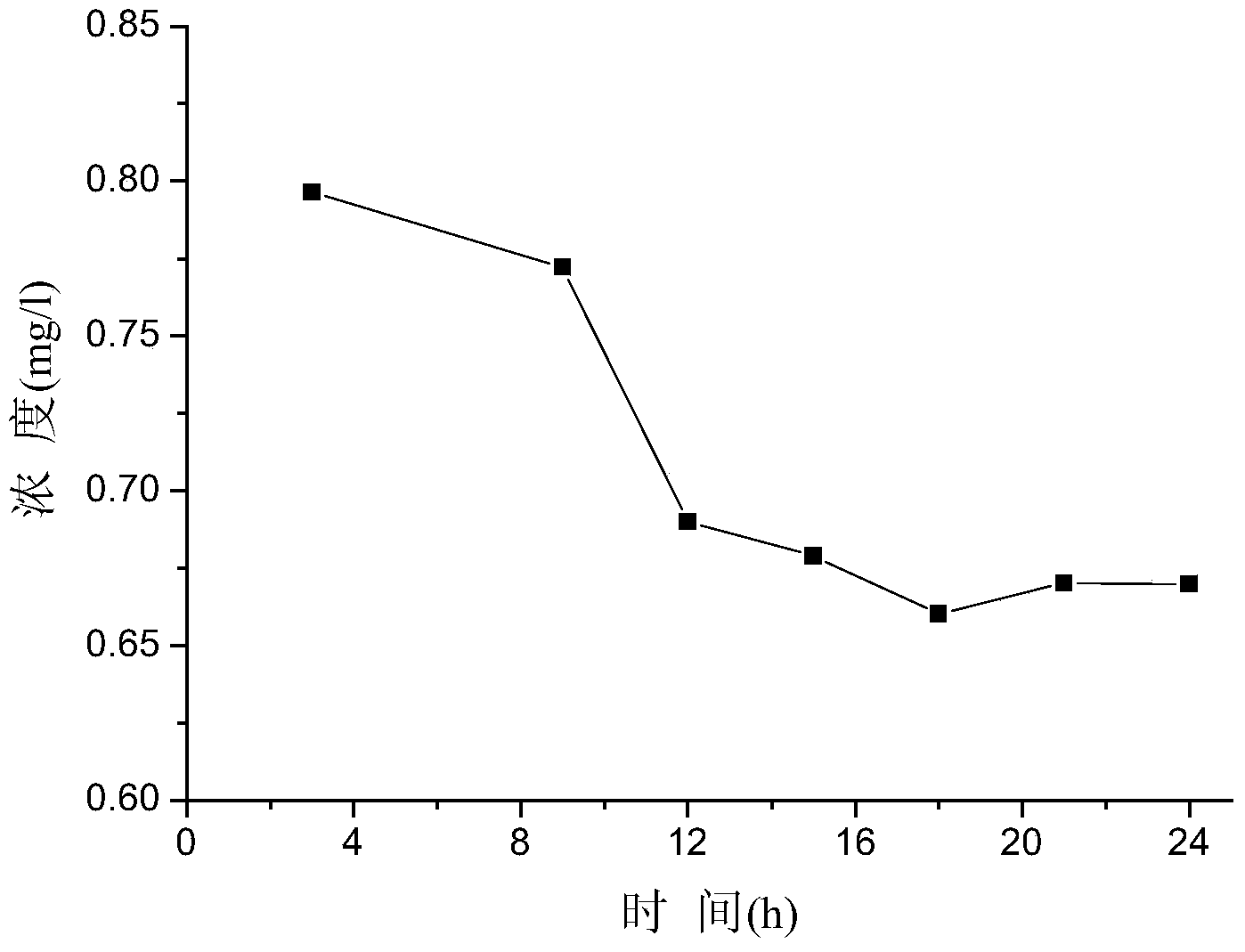

[0031] Influent lead ion concentration 10mg / l, pH is 2.0, and filter material 10 in this embodiment is followed by quartz sand, anthracite, cobblestone from top to bottom, and the aspect ratio of adsorption tower 15 is 5, according to figure 2 As shown in the process flow chart, the water samples of the clear water tank 17 are taken every 3 hours. After 24 hours of continuous treatment, the concentration of lead ions in the effluent is lower than...

Embodiment 2

[0033] lab test

[0034] The device used: a lead-containing wastewater treatment device includes: raw water tank 1, valve 2, flow meter 3 is not provided in this embodiment, water pump 4, alkali tank 5, agitator 6, pH probe 7, reaction sedimentation tank 8, Filtration tower 9, filter material 10, pressure gauge 11 is not provided in this embodiment, tap water tank 12, intermediate pool 13, acid tank 14, adsorption tower 15, polymer hydrogel adsorption material 16, clean water tank 17, filter press 18 is not set in this embodiment.

[0035] Influent lead ion concentration 100mg / l, pH is 2.0, and COD concentration is 70mg / l, filter material 10 is activated carbon, zeolite, cobblestone successively from top to bottom in this embodiment, and the aspect ratio of adsorption tower 15 is 6. According to figure 2 As shown in the process flow chart, water samples from the clear water tank 17 are taken every 2 hours. After 24 hours of continuous treatment, the concentration of lead io...

Embodiment 3

[0037] Pilot test of lead-containing wastewater plant

[0038] The device used: a lead-containing wastewater treatment device includes: raw water tank 1, valve 2, flow meter 3, water pump 4, alkali tank 5, agitator 6, pH probe 7, reaction sedimentation tank 8, filter tower 9, filter material 10. Pressure gauge 11, tap water barrel 12, intermediate pool 13, acid barrel 14, adsorption tower 15, hydrogel adsorption material 16, clear water pool 17, filter press 18.

[0039] In a certain electroplating factory, the concentration of lead ion in the influent is 5 mg / l, the pH is 2.5, the concentration of COD is 80 mg / l, and the concentration of SS is 90 mg / l. The filter material 10 in this embodiment is activated carbon and anthracite from top to bottom. , zeolite, the aspect ratio of adsorption tower 15 is 6, according to figure 2 As shown in the process flow chart, water samples from the clear water tank 17 are taken every 1 day. After continuous treatment for 7 days, the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com